- Offer Profile

- "We are only caretakers of

the world and its resources that we pass on to our children"

(Our slogan)

Wasserkraft Volk AG does the complete design and manufacturing of hydro power stations for the customers. The WKV AG, as the one and only specialized company worldwide, has the know-how for producing the four turbine types (Pelton, Francis, Turgo and Crossflow), as well as synchronous alternators and the complete control system all really made in Germany in our own factoty.

Turbines and Power Plants

- Natural conditions of water courses is significantly

different. Therefore, every order demands an exclusive solution. WKV uses

four different turbine types to transform hydraulic force into electrical

energy:

- WKV Pelton turbines

- WKV Francis turbines

- WKV Turgo turbines

- WKV Crossflow turbines.

Each of these turbine types is suitable for a specific operation area: Different output ratings, various head values, highly unsteady watercourses or high content of floating refuse. In addition, you get WKV speed controllers, WKV water level controllers and WKV switchboards. Everything with well-proven technology “made by WKV AG”.

WKV offers much more than the adaptation of turbine and alternator to the site conditions. For example, a complete range of specific runner speeds allows a perfect alignment to synchronous alternator speeds.

Common for all products: The first-class quality. In our test laboratory, we have proved this beyond doubt and so far achieved highest efficiencies.

Since the company was founded, a big part of our profit has been re-invested into research and development. This makes us the forerunner in the global minihydro industry. We keep our technological lead only by continuous development.Do not buy your turbine plant at a discounter – trust in the specialist!

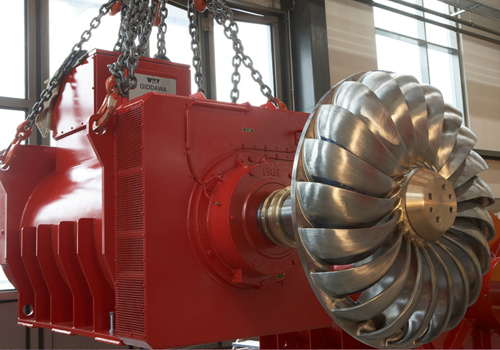

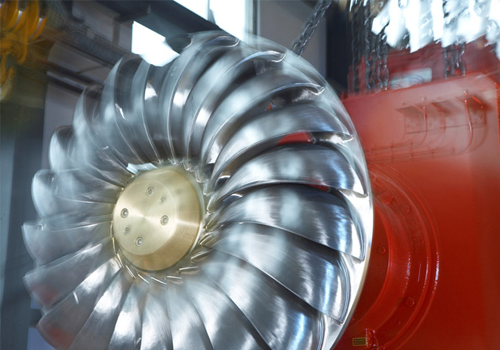

WKV Pelton turbines

- If all good things come from (far) above

Characteristics of WKV Pelton turbines:- Head range from 60 m up to more than 1,500 m

- Capacity up to about 35 MW Single- double-, three-, four-, five- or six-jet designs available

- Horizontal or vertical shaft arrangements

- Jet deflectors for outstanding dynamic performance

- 2 or 4 bearing gen-set arrangements

- Well suited to sites with significant fluctuations in the water flow

- Developed for use in demanding applications with water containing debris

- Optimized jet and runner designs for highest efficiencies

- Spear valve controlled either electrically or hydraulically

- Runner made from high grade, extremely wear resistant, stainless steel

- Maintenance free WKV shaft seal design

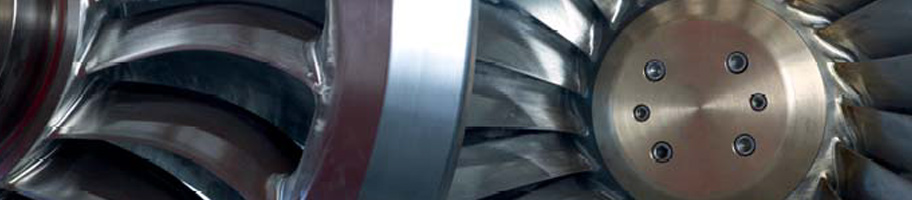

WKV Francis Turbine

- The all-in-one solution. WKV Francis turbines

Characteristics of WKV Francis turbines:- Head range up to far more than 300 m

- Capacity up to about 35 MW

- Excellent peak efficiency

- High efficiency also at partial water flow

- Compact design and low maintenance requirements by rigorous selection of best suited materials and proper design

- 2 or 4 bearing gen-set arrangements

- Bearings rated moderately for more than 100,000 hours of operation

- Guide vane controlled electrically or hydraulically

- Runner made of high-quality and abrasion-proof stainless steel

WKV Turgo turbines

- Effectiveness over a wide range. WKV Turgo turbines

Characteristics of WKV Turgo turbines:- Closes the gap between Francis, Crossflow and Pelton turbines

- Head range 50 ... 300 m

- Output up to 10,000 kW

- Single or double jet design

- Jet deflectors for outstanding dynamic performance (important on long pipelines)

- Significantly less sensitive to contamination than Francis turbines

- Flat efficiency curve shows high efficiency also at partial water flow

- Geometry of stream and runner are optimized for efficiency in WKV’s own laboratory

- The high specific speed allows using the Turgo principle instead of multi-jet Pelton turbines or instead of Francis turbines at lower partial load efficiencies

- Spear valve controlled electrically or hydraulically

- Runner made of extremely wear-resistant stainless steel – not indestructible, but close to it!

- Maintenance-free WKV shaft sealing system

WKV Crossflow turbines

- The economic solution. The PATENTED WKV Crossflow

turbine

Characteristics of WKV Crossflow turbines:- Most modern, PATENTED design

- Head range 5 m up to 150 m

- Capacity up to 3,000 kW

- A split vane construction allows an almost constant efficiency from 100% down to 17% of rated water discharge

- Significant improvements achieved and PATENTED by targeted research and development in WKV’s own test laboratories

- Outstanding runner's stiffness

- Guide vanes with replaceable stainless steel shafts

- Guide vanes controlled electrically or hydraulically

- Easily accessible inspection ports and hatches with low number of bolts

- Proven bearing arrangement, designed by WKV, rated for more than 100,000 operating hours

- Very economic solution where other turbines prove to be too expensive

Energy Conversion & Controls

Switchgears and process controls

- Set out and manage - Switchboards ”Made in

Simonswald“

WKV designs and manufactures the complete set of switchboards and controls in-house, and thus provides a single-point overall responsibility. Each unit is individually adapted to the client’s standards and local regulations.

Your advantages:

- Clear and precise arrangements, quick turnaround on design issues, short deliveries

- Factory testing and inspection of the complete switchboards and control equipment in our own test facilities

- Erection and commissioning by competent staff

- Only first-class components are used

WKV supplies a complete line of equipment from low voltage equipment to the feeder at medium or high voltage level.

- Conventional control panels

- PLC based controls

- Remote control (SCADA)

- Annunciation and display equipment

- Low voltage switchboards up to 3 500 A

- Medium voltage switchboards up to 36 kV

- High voltage switchboards

- Transformers

- Allocation metering towards mains operators

- Complete wiring inside the power plant

WKV control systems

- A reliable arrangement.

Digital/analogue speed governor type SRE 2000

This WKV development is unique in the world of controls as it combines the advantages of both digital and analogue controls.- Direct display of the main control parameters

- Dynamic PID controls with the option for external disturbance application ensure stability even in the case of long penstocks or unstable grids

- Modular 19” rack design for easy implementation and replacement of components

- Protection against external faults, all I/O circuits are protected against external short-circuiting and reverse polarity

- Easy adjustment of all main parameters by use of a simple screw driver, no programming, no software or terminal, no laptop required

- No pick-ups required for speed sensing

- Designed for operation with PLC based controls or a remote control system

- Suited for speed control, output control, discharge or level control, as well as for double-regulated units (injector/deflector or guide vanes/runner blades)

- Durable and user-friendly design and technology

- WKV offers a lifelong guarantee for supply of spare parts and services. All control units are backwards-compatible!

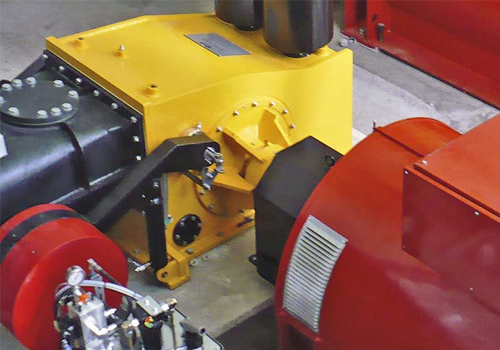

Hydraulic devices for speed control and parallel operation with mains

-

- WKV offers a complete range of hydraulic power units for control applications. This includes simple actuators for operation on a grid (level or discharge control) as well as the most complex applications involving isolated network or grid-parallel operation.

- Designed for decades of continous operation – only the best components are used

- Low-pressure hydraulics for extended life service

- Energy-saving designs

- Typically no high-pressure accumulators that need severe maintenance

- WKV manufactures the complete range of governors in-house – another benefit for you!

Mechanical governors and their maintenance

- For some applications mechanical governors may provide

significant advantages.

WKV offers a full line of such governors manufactured in-house:

- Robust and well-proven technology

- Completely without electronics – best suited for applications in remote locations

WKV level control for grid-parallel operation

-

- Designed to ensure best possible use of the available water flows and most economical operation!

- PLC controlled operation to achieve optimum efficiency for multi-jet impulse turbines as well as for twin-cell Crossflow turbines

- Intake water level indicator

- Surge-protected water level sensors provide safe operation even under adverse environmental conditions

- User friendly setpoint adjustment.

Electronic load controller

-

- Designed for small units up to 800 kW supplying isolated loads as well as for the emergency power supply of grid-connected units.

- Excellent frequency-accuracy even during load acceptance or rejection

- Heavy duty industrial grade electronics especially designed for extreme ambient conditions

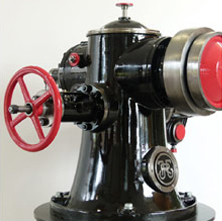

´JAHNS speed controllers

- Dated models of JAHNS speed controllers are prepared for proper operation for coming decades. We use only original documentation and original replacement parts.

The robust and durable performance of these speed controllers works completely without electric energy and is so far suitable for small power plants that shall be operated in islated mode. A refurbishment costs just a fractional amount of a new controller.

Of course, we will also deliver brandnew original JAHNS speed controllers if needed!

Synchronous Alternators

Basics

- Background: Why WKV High Efficiency Alternators provide a

better solution

The basics are unchangeable. The physical laws are permanent. So, it’s vital always to make the best out of them!- A highly skilled and talented team of engineers, designers and technicians at WKV AG is marching towards efficient and innovative solutions. Besides optimizing the alternators magnetically and electro-dynamically, our main focus is to provide a perfect fit to the requirements of our customers in terms of electrical and mechanical characteristics.

- Sophisticated production technology and our know how guarantee highest quality products and reliably on-time delivery.

- Deliberated magnetic and mechanical design in connection with using only first-class material are granting highest efficiencies.

- We are combining most modern production technology with solid input of manual work, because: Quality can just be planned, but finally it has to be realistic in production!

- When taking your choice for alternators for hydro power and other prime movers, trust on the expertise and innovation of specialists - trust WKV!

Mechanic Design

-

General design

The alternators consist of the main internal-pole generator and the external-pole exciter machine. The entire design is configured for highest reliability, quality and durability.

Stator and bearing housings The stator housing is a solid welded construction. The stator core is made up of low-loss laminations, pressed together by means of pressure plates to form a compact unit.

The stator insulation system is based on temperature class “H” materials for low voltage alternators and class “F” for medium voltage alternators, according to EN 60034-1 / VDE 0530-1. The winding overhangs and connections are supported by fastening elements and firmly linked by mechanical means to guard against loads caused by electro-dynamic forces. An auxiliary exciter winding located in the main stator slots provides power to the automatic voltage regulator. The exciter machine stator is fixed in the non-drive end bearing housing.

The bearing housings are also made of rigidly welded construction with integrated machine feet, in order to ensure a perfectly stiff fixing to the foundation.

Electric Design

- Electric operation principle

The auxiliary winding, via the AVR’s control circuit, feeds electrical energy to the exciter winding of the exciter machine. This eliminates the need of additional auxiliary exciter machines or the often used current transformer assemblies. Power supply to the AVR of course is performed also in case of short circuit at the power terminals, so that a sufficiently high short circuit current is produced for granting selectivity of the power plant.

The exciter power, transformed to the 3-phase rotor winding of the exciter machine, is converted to DC power by means of a rotating diode bridge consisting of generously sized diodes and protective elements and then supplied to the rotor of the main generator. Permanent magnets that are located in the stator of the exciter machine ensure the self-excitation of the system.

The voltage control of the main generator at fluctuating loads is performed by changing the exciter current in the stator winding of the exciter machine via the power section of the automatic voltage regulator.