- Offer Profile

- YASKAWA Electric is

one of the world’s leading manufacturers in the fields of drive technology,

industrial automation and robotics based in Kitakyushu, Japan. Founded in

1915, we see ourselves as a pioneer in these sectors, always striving to

optimise the productivity and efficiency of machines and industrial systems

with our innovations.

For over 100 years now, our products and solutions have been supporting automation in a wide variety of industrial processes including mining, mechanical engineering and toolmaking, as well as the automotive, packaging, wood processing, lift, textile and semiconductor industries.

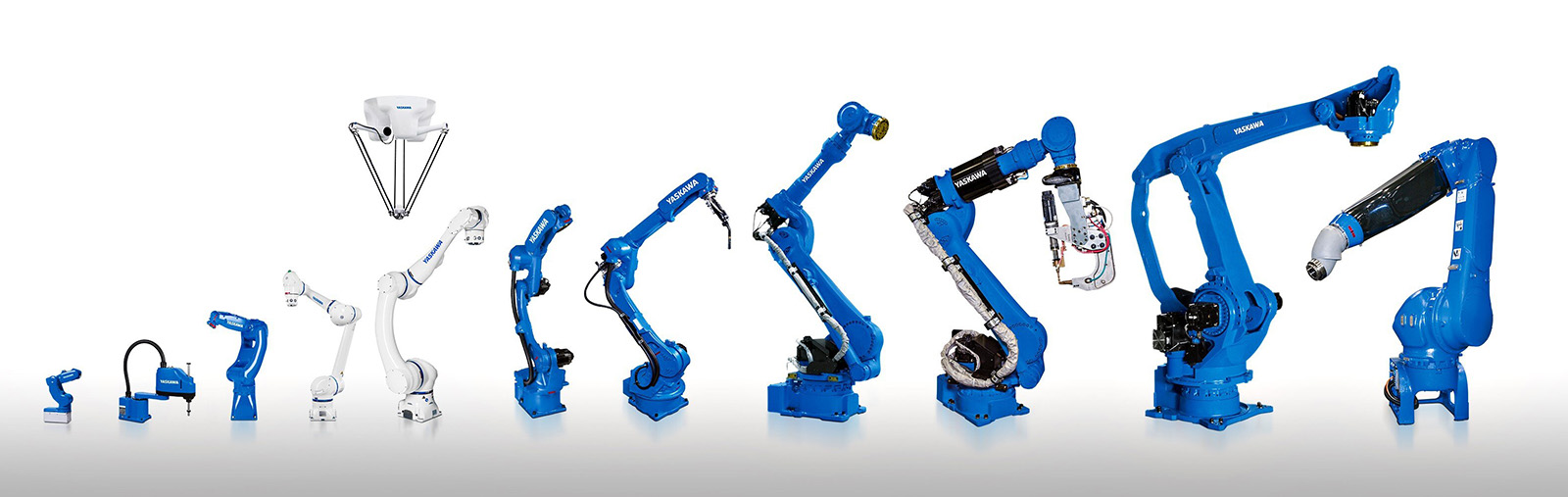

MOTOMAN robots

Collaborative Robots - HC Series

-

When you hear the term “industrial robots”, you may associate this with images of welding or painting processes at automobile plants. Now however, robots are used in many more fields and across applications including logistics, pharma and food manufacturing. In recent years, skilled labour shortages at manufacturing sites have become an increasing challenge globally so that automation, utilizing robots has become increasingly significant. In addition, the needs for the utilization of robots are diversifying these days as we assign multiple jobs to one robot, not just make it repeat a simple single task as before.

Nevertheless, there are still challenges for the small and mid-sized company to install robots as the working area for humans has to be separated from industrial robots by a safety fence, which requires sufficient space and additional installation costs. The Yaskawa human collaborative robot (HC10) is a new generation of robotics that is capable, affordable, versatile, simple to use and built with the industrial strength for which Yaskawa products are known. These robots are for customers looking for easy automation, a robot to automate tasks, that can work in close proximity to humans.

HC10DTP Classic: Perfect entry-level model for collaborative automation

-

The MOTOMAN HC10DTP Classic is the perfect cobot for entry-level collaborative automation.

It offers a payload of 10 kg, an absolute reach (center of rotation S/L axis to center of rotation R/T axis) of 1,379 mm and an effective reach (center of rotation S/L axis to working point P) of 1,200 mm.

Typical applications are collaborative, simple assistance tasks in handling and assembly, palletizing, loading/unloading of machine tools or quality inspection.

The MOTOMAN HC10DTP Classic can be operated and programmed using hand guiding, standard teach pendant or the intuitive Smart Pendant. For particularly efficient programming via hand guiding, it has Direct Teach buttons on the wrist that can be used to accept taught positions immediately without having to confirm them on the teach pendant. This reduces programming times and makes it suitable for both professional system integrators and newbies. Many safety functions, e.g. automatic retraction from a clamping situation, or simply pushing the robot away with resumption of movement, distinguish it as a professional collaborative robot.

The MOTOMAN HC10DTP Classic is switchable between safely monitored operation and full power and speed, with this mixed operation (hybrid robot) it achieves very good cycle times. Media cables for the supply of grippers or tools are pre-routed in the arm and are led out at the wrist, so that in many cases bulky external cable packages are not required.

- NUMBER OF AXES: 6

- PAYLOAD: 10 kg

- MAX. WORKING RANGE: 1,379 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 48 kg

- POWER SUPPLY: 1 kVA

- S AXIS: 130 °/s

- L AXIS: 130 °/s

- U AXIS: 180 °/s

- R AXIS: 180 °/s

- B AXIS: 250 °/s

- T AXIS: 250 °/s

- MOUNTING OPTIONS: Ceiling

HC10DTP: Powerful cobot for simple industrial applications in harsh environments

-

The MOTOMAN HC10DTP is a human-collaborative robot with a payload of 10 kg. It provides an absolute reach (S/L-Axis center of rotation to R/T-Axis center of rotation) of 1,379 mm and an effective reach (S/L-Axis center of rotation to Point P of) of 1,200 mm.

Specifications like high IP67 (dust/liquid proof) protection rating, food grade grease lubrication in all joints, and a a special drip proof coating allows the robot to be used in certain food related applications.

Further applications are collaborative, simple assistance tasks in handling and assembly, palletizing, loading/unloading of machine tools or quality inspection.

The MOTOMAN HC10DTP can be operated and programmed using hand guiding, standard teach pendant or the intuitive Smart Pendant. For particularly efficient programming via hand guiding, it has Direct Teach buttons on the wrist that can be used to accept taught positions immediately without having to confirm them on the teach pendant. This reduces programming times and makes it suitable for both professional system integrators and newbies. Many safety functions, e.g. automatic retraction from a clamping situation, or simply pushing the robot away with resumption of movement, distinguish it as a professional collaborative robot.

The MOTOMAN HC10DTP is switchable between safely monitored operation and full power and speed, with this mixed operation (hybrid robot) it achieves very good cycle times. Media cables for the supply of grippers or tools are pre-routed in the arm and are led out at the wrist, so that in many cases bulky external cable packages are not required.

- NUMBER OF AXES: 6

- PAYLOAD: 10 kg

- MAX. WORKING RANGE: 1,379 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 58 kg

- POWER SUPPLY: 1 kVA

- S AXIS: 130 °/s

- L AXIS: 130 °/s

- U AXIS: 180 °/s

- R AXIS: 180 °/s

- B AXIS: 250 °/s

- T AXIS: 250 °/s

HC10DTFP: Ideal cobot for sensitive environments

-

The MOTOMAN HC10DTFP is a 6-axis robot suitable for collaborative operation with a payload of up to 10 kg. It provides an absolute reach (S/L-Axis center of rotation to R/T-Axis center of rotation) of 1,379 mm and an effective reach (S/L-Axis center of rotation to Point P of) of 1,200 mm.

The MOTOMAN HC10DTFP has a chemical proof surface resisting acid or alcaline cleaning fluid. Complying to EN 60529-IP67, it is dust and waterproof protected to operate in harsh environments. Protection class IP67 for Food Grade Grease and ISO cleanroom class 5 allow these robots to be used in food related applications, as well as in Life Science Applications.

The MOTOMAN HC10DTFP can be operated and programmed using hand guiding, standard teach pendant or the intuitive Smart Pendant. For particularly efficient programming via hand guiding, it has Direct Teach buttons on the wrist that can be used to accept taught positions immediately without having to confirm them on the teach pendant. This reduces programming times and makes it suitable for both professional system integrators and newbies. Many safety functions, e.g. automatic retraction from a clamping situation, or simply pushing the robot away with resumption of movement, distinguish it as a professional collaborative robot.

It is switchable between safely monitored operation and full power and speed, with this mixed operation (hybrid robot) it achieves very good cycle times. Media cables for the supply of grippers or tools are pre-routed in the arm and are led out at the wrist, so that in many cases bulky external cable packages are not required.

The HC10DTFP can be supplied with both the YRC1000 robot controller and the YRC1000micro compact controller.

- NUMBER OF AXES: 6

- PAYLOAD: 10 kg

- MAX. WORKING RANGE: 1,379 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 58 kg

- POWER SUPPLY: 1 kVA

- S AXIS: 130 °/s

- L AXIS: 130 °/s

- U AXIS: 180 °/s

- R AXIS: 180 °/s

- B AXIS: 250 °/s

- T AXIS: 250 °/s

HC20DTP: Powerful cobot with high reach

-

The MOTOMAN HC20DTP is a human-collaborative robot with a superior payload of 20 kg. It provides an absolute reach (S/L-Axis center of rotation to R/T-Axis center of rotation) of 1,900 mm and an effective reach (S/L-Axis center of rotation to Point P of) of 1,700 mm.

This robot is perfect for collaborative fenceless Palletizing and Handling installations, combining safe operation and high speed.

Specifications like high IP67 (dust/liquid proof) protection rating, food grade grease lubrication in all joints, and a a special drip proof coating allows the robot to be used in certain food related applications.

The MOTOMAN HC20DTP can be operated and programmed using hand guiding, standard teach pendant or the intuitive Smart Pendant. For particularly efficient programming via hand guiding, it has Direct Teach buttons on the wrist that can be used to accept taught positions immediately without having to confirm them on the teach pendant. This reduces programming times and makes it suitable for both professional system integrators and newbies. Many safety functions, e.g. automatic retraction from a clamping situation, or simply pushing the robot away with resumption of movement, distinguish it as a professional collaborative robot.

The MOTOMAN HC20DTP is switchable between safely monitored operation and full power and speed, with this mixed operation (hybrid robot) it achieves very good cycle times. Media cables for the supply of grippers or tools are pre-routed in the arm and are led out at the wrist, so that in many cases bulky external cable packages are not required.

- NUMBER OF AXES: 6

- PAYLOAD: 20 kg

- MAX. WORKING RANGE: 1,900 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 140 kg

- POWER SUPPLY: 1.5 kVA

- S AXIS: 80 °/s

- L AXIS: 80 °/s

- U AXIS: 120 °/s

- R AXIS: 130 °/s

- B AXIS:

180 °/s

- T AXIS: 180 °/s

HC30PL: Collaborative robot with high payload

-

The MOTOMAN HC30PL is a human-collaborative robot with a superior payload of 30 kg. It provides a reach (S/L-Axis center of rotation to R/T-Axis center of rotation) of 1,700 mm.

This cobot is perfect for collaborative fenceless Palletizing installations, combining safe operation and high speed.

Specifications like high IP67 (dust/liquid proof) protection rating, food grade grease lubrication in all joints, and a a special drip proof coating allows the cobot to be used in certain food related applications.

The MOTOMAN HC30PL can be operated and programmed using hand guiding, standard teach pendant or the intuitive Smart Pendant. For particularly efficient programming via hand guiding, it has Direct Teach buttons on the wrist that can be used to accept taught positions immediately without having to confirm them on the teach pendant. This reduces programming times and makes it suitable for both professional system integrators and newbies. Many safety functions, e.g. automatic retraction from a clamping situation, or simply pushing the cobot away with resumption of movement, distinguish it as a professional collaborative robot.

The MOTOMAN HC30PL is switchable between safely monitored operation and full power and speed, with this mixed operation (hybrid robot) it achieves very good cycle times. Media cables for the supply of grippers or tools are pre-routed in the arm and are led out at the wrist, so that in many cases bulky external cable packages are not required.

NUMBER OF AXES: 6

PAYLOAD: 30 kg

MAX. WORKING RANGE: 1,700 mm

REPEATABILITY: 0.05 mm

WEIGHT: 140 kg

POWER SUPPLY: 1.5 kVA

S AXIS: 80 °/s

L AXIS: 80 °/s

U AXIS: 120 °/s

R AXIS: 130 °/s

B AXIS: 180 °/s

T AXIS: 180 °/s

MOUNTING OPTIONS: Floor

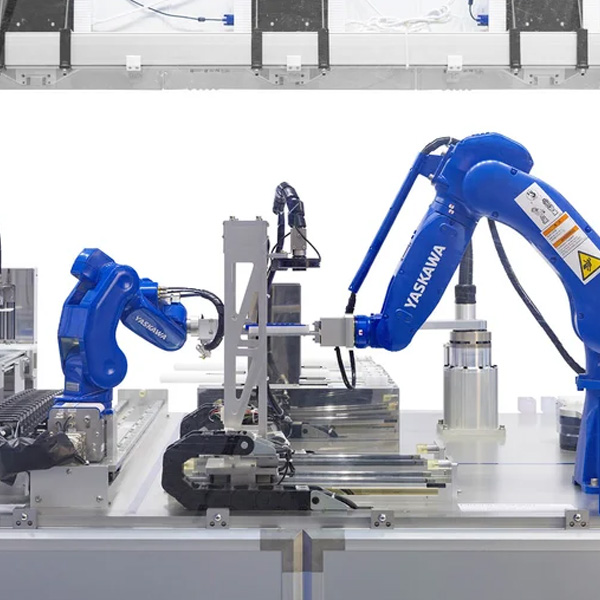

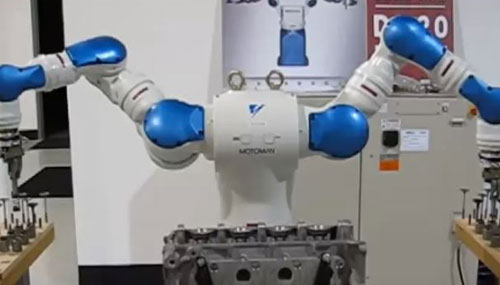

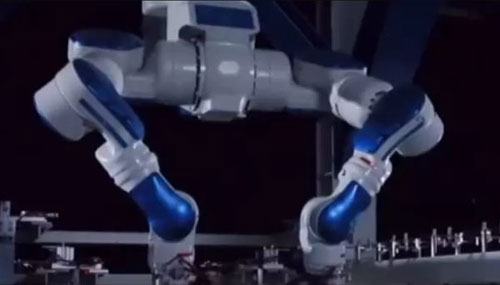

Handling & Assembly Robots - SDA Series

- The MOTOMAN SDA models are slim and agile 15-axis dual-arm robots with "human-like" flexibility of movement and fast acceleration.

This makes it the ideal solution for a variety of operations such as assembly, part transfer, machine tending, packaging and other handling tasks. The CSDA10F model is designed for clean room use.

The SDA models have payloads ranging from 5 kg to 40 kg and working envelopes ranging from 845 mm to 1,323 mm. Both robot arms can work together synchronously or perform different tasks simultaneously. Due to its small footprint it can operate in confined spaces, saving valuable floor space.

SDA5F

- The MOTOMAN SDA5F has a payload of 5 kg (per arm) and a reach of 845 mm.

Technical Details- Number of axes 15

- Payload 5 kg

- Max working range 845 mm

- Repeatability 0.06 mm

- Weight 110 kg

- Power supply 1.4 kVA

- S Axis 180 °/sec

- L Axis 80 °/sec

- U Axis 120 °/sec

- R Axis 130 °/sec

- B Axis 180 °/sec

- T Axis 180 °/sec

- Mounting options Ceiling, Wall, Floor

CSDA10F

- The MOTOMAN CSDA10F has a payload of 10 kg (per arm) and a reach of 720 mm and is designed for clean room/laboratory use. Technical Details

- Number of axes 15

- Payload 10 kg

- Max working range 720 mm

- Repeatability 0.1 mm

- Weight 220 kg

- Power supply 2 kVA

- S Axis 130 °/sec

- L Axis 170 °/sec

- U Axis 170 °/sec

- R Axis 200 °/sec

- B Axis 200 °/sec

- T Axis 400 °/sec

- Mounting options Floor

SDA10F

- The MOTOMAN SDA10F has a payload of 10 kg (per arm) and a reach of 845 mm.

Technical Details- Number of axes 15

- Payload 10 kg

- Max working range 720 mm

- Repeatability 0.1 mm

- Weight 220 kg

- Power supply 2 kVA

- S Axis 130 °/sec

- L Axis 170 °/sec

- U Axis 170 °/sec

- R Axis 200 °/sec

- B Axis 200 °/sec

- T Axis 400 °/sec

- Mounting options Floor

SDA20F

- The MOTOMAN SDA20F provides a payload of 20 kg (per arm) and a reach of 1,323 mm.

It is also available with protection class IP65/67 to operate in harsh environments.

Technical Details- Number of axes 15

- Payload 20 kg

- Max working range 1,323 mm

- Repeatability 0.1 mm

- Weight 380 kg

- Power supply 4.4 kVA

- S Axis 125 °/sec

- L Axis 130 °/sec

- U Axis 170 °/sec

- R Axis 170 °/sec

- B Axis 200 °/sec

- T Axis 400 °/sec

- Mounting options Floor

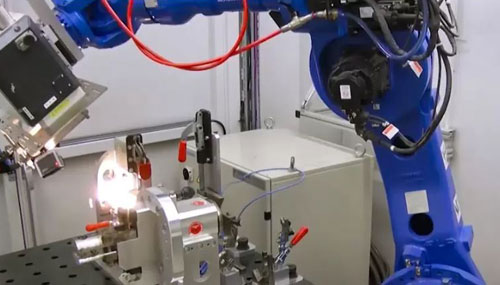

Welding and Cutting Robots - AR Series

-

The MOTOMAN AR Series Robots provide outstanding speed and accuracy for all kinds of demanding arc welding and thermal cutting applications, supporting all kind of welding and cutting methods and equipment.

With a full range portfolio of working ranges between 700 and 3,124 mm reach, often in combination with our positioners, tracks and gantries, AR Series Robots can weld any kind or dimension of workpieces.

AR900

- The smallest MOTOMAN arc welding robot AR900 provides high path accuracy and great stability.

With a payload of up to 7 kg and a working range of 927 mm this robot enables welding of small workpieces with high-quality results.

Technical Details- Number of axes 6

- Payload 7 kg

- Max working range 927 mm

- Repeatability 0.1 mm

- Weight 34 kg

- Power supply 1 kVA

- S Axis 375 °/sec

- L Axis 315 °/sec

- U Axis 410 °/sec

- R Axis 550 °/sec

- B Axis 550 °/sec

- T Axis 1000 °/sec

- Mounting options Ceiling, Wall, Floor

AR700

- The compact MOTOMAN AR700 arc welding robot provides high path accuracy and great stability.

With a payload of up to 8 kg and a working range of 727 mm this robot enables accurate welding of small workpieces with high-quality results.

Technical Details- Number of axes 6

- Payload 7 kg

- Max working range 927 mm

- Repeatability 0.1 mm

- Weight 34 kg

- Power supply 1 kVA

- S Axis 375 °/sec

- L Axis 315 °/sec

- U Axis 410 °/sec

- R Axis 550 °/sec

- B Axis 550 °/sec

- T Axis 1000 °/sec

- Mounting options Ceiling, Wall, Floor

AR1440

- The six-axis MOTOMAN AR1440 robot provides high performance to achieve optimal results in extremely difficult conditions.

With a high payload of up to 12 kg and a wide working range of 1,440 mm this robot supports welding of bulky workpieces and mounting a broad variety of heavy welding and cutting equipment.

Technical Details- Number of axes 6

- Payload 12 kg

- Max working range 1,440 mm

- Repeatability 0.02 mm

- Weight 150 kg

- Power supply 1.5 kVA

- S Axis 260 °/sec

- L Axis 230 °/sec

- U Axis 260 °/sec

- R Axis 470 °/sec

- B Axis 470 °/sec

- T Axis 700 °/sec

- Mounting options Ceiling, Wall, Floor

AR2010

- The 6-axis robot MOTOMAN AR2010 of our AR-series, thanks to its high path accuracy, is an optimal robot for arc welding applications.

With a payload of up to 12 kg and a wide working range of 2010 mm this robot supports welding of bulky workpieces.

Technical Details- Number of axes 6

- Payload 12 kg

- Max working range 2,010 mm

- Repeatability 0.03 mm

- Weight 260 kg

- Power supply 2 kVA

- S Axis 210 °/sec

- L Axis 210 °/sec

- U Axis 220 °/sec

- R Axis 435 °/sec

- B Axis 435 °/sec

- T Axis 700 °/sec

- Mounting options Floor, Wall, Ceiling

AR3120

- The six-axis robot MOTOMAN AR3120 provides the widest motion range of our AR-series and high path accuracy for optimum results of arc welding applications.

With a payload of up to 20 kg and a motion range of 3,124 mm, this robot supports welding of bulky workpieces.

Technical Details- Number of axes 6

- Payload 20 kg

- Max working range 3124 mm

- Repeatability 0.07 mm

- Weight 560 kg

- Power supply 2 kVA

- S Axis 190 °/sec

- L Axis 190 °/sec

- U Axis 190 °/sec

- R Axis 400 °/sec

- B Axis 430 °/sec

- T Axis 630 °/sec

- Mounting options Ceiling, Wall, Floor

AR1730

-

- The powerful six-axis MOTOMAN AR1730 robot provides high performance to achieve optimal results in extremely difficult conditions.

- With a high payload of up to 25 kg and a wide working range of 1,730 mm this robot supports welding of bulky workpieces and mounting a broad variety of heavy welding and cutting equipment.

Technical Details- Number of axes 6

- Payload 20 kg

- Max working range 3124 mm

- Repeatability 0.07 mm

- Weight 560 kg

- Power supply 2 kVA

- S Axis 190 °/sec

- L Axis 190 °/sec

- U Axis 190 °/sec

- R Axis 400 °/sec

- B Axis 430 °/sec

- T Axis 630 °/sec

- Mounting options Ceiling, Wall, Floor

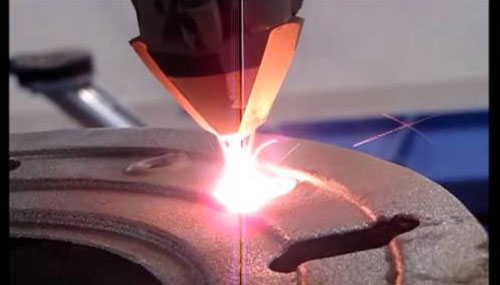

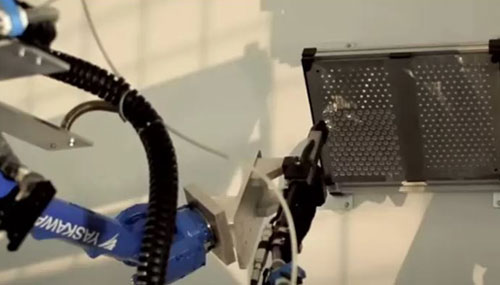

Welding and Cutting Robots - GA Series

-

The MOTOMAN GA robot is an highly accurate robot model for high-precision laser applications such as laser cutting, (remote) laser welding or cladding.

Due to high payload, the robot can manipulate even large laser heads with excellent performance - circles, curves and linear paths.

GA50: 6-axis robot for high precision Laser Welding, Cutting & Cladding

-

The MOTOMAN GA50 robot is designed for applications that require high precision and path accuracy, such as 3D laser welding or cutting. It provides a payload of 50 kg and a high reach of 2,038 mm, which allows processing of large workpieces using common laser heads.

In combination with the advanced Sigma-7 servo drive technology and tolerance-optimized precision gearboxes, this manipulator achieves very high positioning and path accuracy paired with high mechanical stiffness.

The MOTOMAN YRC1000 high-performance robot controller offers a wide range of path-related programming functions, interfaces and communication options for integrating the robot.

- NUMBER OF AXES: 6

- PAYLOAD: 50 kg

- MAX. WORKING RANGE: 2,038 mm

- REPEATABILITY: 0.01 mm

- WEIGHT: 855 kg

- POWER SUPPLY: 4.5 kVA

- S AXIS: 150 °/s

- L AXIS: 150 °/s

- U AXIS: 150 °/s

- R AXIS: 250 °/s

- B AXIS: 250 °/s

- T AXIS: 250 °/s

- MOUNTING OPTIONS: Floor

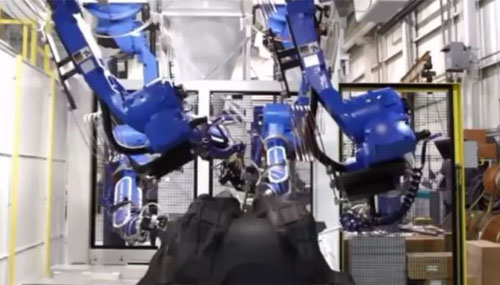

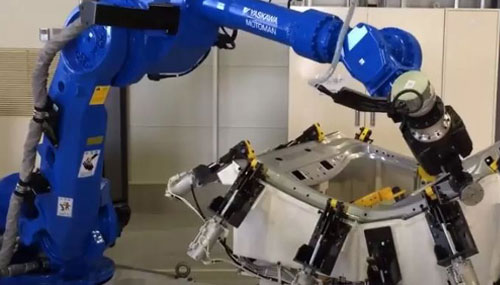

High Performance Spot Welding & Handling Robots: SP Series

-

The MOTOMAN SP Series are highly flexible and powerful spot welding robots, which are also suitable for handling applications. Their slim design enables a small footprint, allowing them to be positioned in confined spaces, and impresses with a higher maximum motion range.

With payloads from 80 to 250 kg, the MOTOMAN SP Series is ideal for a wide range of common spot-welding guns and technologies, including in particular servo-controlled welding guns with robotic gun balancing.

SP80: Compact Spot Welding & Handling Robot

-

The MOTOMAN SP80 is the smallest spot welding and handling robot of the MOTOMAN SP series. It provides 80 kg payload (including C-adapter) and 2236 mm working range for servo-controlled lightweight welding guns.

This robot is suitable for compact spot welding lines in car body construction with high robot density, for economical welding of small subassemblies, and for space-saving installation on a positioner.

The MOTOMAN SP80 is controlled by the compact and powerful MOTOMAN YRC1000 controller and features the latest Yaskawa Sigma-7 servo drive technology which offers high dynamics and energy efficiency, and enables outstanding cycle times.

- Extra slim design

- Large working range

- NUMBER OF AXES: 6

- PAYLOAD: 80 kg

- MAX. WORKING RANGE: 2,236 mm

- REPEATABILITY: 0.03 mm

- WEIGHT: 630 kg

- POWER SUPPLY: 4 kVA

- S AXIS: 170 °/s

- L AXIS: 140 °/s

- U AXIS: 160 °/s

- R AXIS: 230 °/s

- B AXIS: 230 °/s

- T AXIS: 350 °/s

- MOUNTING OPTIONS: Ceiling, Wall, Floor

SP100: Compact Spot Welding & Handling Robot

-

The MOTOMAN SP100 is a compact spot welding and handling robot providing 100 kg payload (including C-adapter) and 2236 mm working range for servo-controlled lightweight welding guns.

This robot is suitable for compact spot welding lines in car body construction with high robot density, for economical welding of small subassemblies, and for space-saving installation on a positioner.

The MOTOMAN SP100 is controlled by the compact and powerful MOTOMAN YRC1000 controller and features the latest Yaskawa Sigma-7 servo drive technology which offers high dynamics and energy efficiency, and enables outstanding cycle times.

- NUMBER OF AXES: 6

- PAYLOAD: 100 kg

- MAX. WORKING RANGE: 2,236 mm

- REPEATABILITY: 0.03 mm

- WEIGHT: 660 kg

- POWER SUPPLY: 5 kVA

- S AXIS: 140 °/s

- L AXIS: 110 °/s

- U AXIS: 127 °/s

- R AXIS: 175 °/s

- B AXIS: 175 °/s

- T AXIS: 255 °/s

- MOUNTING OPTIONS: Floor

SP165-105: Compact Spot Welding & Handling Robot with High Reach

-

The MOTOMAN SP165-105 is a spot welding and handling robot with a long reach of over 3 meters. This robot is perfect for handling tasks related to spot welding, e.g. workpiece handling with stationary welding gun. It can be used for a wide range of common spot welding guns and technologies, especially also for servo-controlled welding guns with robotassisted gun balance.

Its slim design does not require mechanical counterweight compensation and allows low moving masses as well as higher accelerations and speeds. The stable wrist is particularly suitable for small and fast positioning movements, as are common in spot welding applications.

The MOTOMAN SP165-105 is controlled by the compact and powerful MOTOMAN YRC1000 controller and features the latest Yaskawa Sigma7 servo drive technology, is state-of-the-art in terms of dynamics and energy efficiency, and enables outstanding cycle times.

- Versatile application possibilities

- Long reach but small footprint

- High dynamics and repeatability

- High energy efficiency

- NUMBER OF AXES: 6

- PAYLOAD: 105 kg

- MAX. WORKING RANGE: 3,058 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 1,090 kg

- POWER SUPPLY: 5 kVA

- S AXIS: 125 °/s

- L AXIS: 113 °/s

- U AXIS: 125 °/s

- R AXIS: 182 °/s

- B AXIS: 175 °/s

- T AXIS: 265 °/s

- MOUNTING OPTIONS: Floor

SP150R: Shelf-mounted Spot Welding & Handling Robot

-

The MOTOMAN SP150R is a powerful 6-axis shelf-mounted spot welding and handling robot. Combined with its long reach of over 3 meters, it has a significantly extended working space below its installation level. It is used where the robot is mounted in an elevated position and needs to work downwards, e.g. on a steel structure.

With its maximum payload of 150 kg (including C-adapter), it is suitable for a wide range of common spot-welding guns and grippers, especially also for servo-controlled welding guns as an integrated 7th axis with robot-supported gun compensation.

The MOTOMAN SP150R is controlled by the compact and powerful MOTOMAN YRC1000 controller and features the latest Yaskawa Sigma7 servo drive technology, is state-of-the-art in terms of dynamics and energy efficiency, and enables outstanding cycle times.

- Possibility of mounting on elevated position

- Versatile application possibilities & small footprint

- High dynamics and repeatability

- High energy efficiency

- NUMBER OF AXES: 6

- PAYLOAD: 150 kg

- MAX. WORKING RANGE: 3,140 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 1,760 kg

- POWER SUPPLY: 5 kVA

- S AXIS: 105 °/s

- L AXIS: 105 °/s

- U AXIS: 105 °/s

- R AXIS: 175 °/s

- B AXIS: 150 °/s

- T AXIS: 240 °/s

- MOUNTING OPTIONS: Shelf-Mounted

SP165: Compact Spot Welding & Handling Robot

-

The MOTOMAN SP165 is a high-performance standard spot welding and handling robot with 165 kg payload (including C-adapter). It is suitable for a wide range of common spot-welding guns and technologies, especially also for servo-controlled welding guns with robot-assisted gun alignment.

Its slim design does not require a mechanical counterbalance and allows low moving masses as well as higher accelerations and speeds. The stable wrist is particularly suitable for small and fast positioning movements, as are common in spot welding applications.

The MOTOMAN SP165 is controlled by the compact and powerful MOTOMAN YRC1000 controller and features the latest Yaskawa Sigma7 servo drive technology, is state-of-the-art in terms of dynamics and energy efficiency, and enables outstanding cycle times.

- Versatile application possibilities

- Slim design enables small footprint

- High dynamics and repeatability

- High energy efficiency

- NUMBER OF AXES: 6

- PAYLOAD: 165 kg

- MAX. WORKING RANGE: 2,702 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 1,020 kg

- POWER SUPPLY: 5 kVA

- S AXIS: 125 °/s

- L AXIS: 115 °/s

- U AXIS: 125 °/s

- R AXIS: 182 °/s

- B AXIS: 175 °/s

- T AXIS: 265 °/s

- MOUNTING OPTIONS: Floor

SP185R: Compact Spot Welding & Handling Robot with High Reach

-

The MOTOMAN SP185R is a powerful 6-axis shelf-mounted spot welding and handling robot. Combined with its long reach of over 3 meters, it has a significantly extended working space below its installation level. It is used where the robot is mounted in an elevated position and needs to work downwards, e.g. on a steel structure.

With its maximum payload of 185 kg (including C-adapter), it is suitable for a wide range of common spot-welding guns and grippers, especially also for servo-controlled welding guns as an integrated 7th axis with robot-supported gun compensation.

The MOTOMAN SP185R is controlled by the compact and powerful MOTOMAN YRC1000 controller and features the latest Yaskawa Sigma7 servo drive technology, is state-of-the-art in terms of dynamics and energy efficiency, and enables outstanding cycle times.

- Possibility of mounting on elevated position

- Versatile application possibilities & small footprint

- NUMBER OF AXES: 6

- PAYLOAD: 185 kg

- MAX. WORKING RANGE: 3,140 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 1,830 kg

- POWER SUPPLY: 5 kVA

- S AXIS: 90 °/s

- L AXIS: 85 °/s

- U AXIS: 85 °/s

- R AXIS: 120 °/s

- B AXIS: 120 °/s

- T AXIS: 190 °/s

- MOUNTING OPTIONS: Shelf-Mounted

SP210: Spot Welding Robot with High Payload

-

The MOTOMAN SP210 is a powerful spot welding and handling robot with a payload of 210 kg (including C-adapter). It is suitable for a wide range of common spot-welding guns and technologies, especially also for servo-controlled welding guns with robot-assisted gun alignment.

Its slim design does not require a mechanical counterbalance balancer and allows low moving masses as well as higher accelerations and

speeds. The stable wrist is particularly suitable for small and fast positioning movements, as are common in spot welding applications.The MOTOMAN SP210 is controlled by the compact and powerful MOTOMAN YRC1000 controller and features the latest Yaskawa Sigma7 servo drive technology, is state-of-the-art in terms of dynamics and energy efficiency, and enables outstanding cycle times.

- Versatile application possibilities

- High payload & small footprint

- High repeatability

- Versatile application possibilities

- NUMBER OF AXES: 6

- PAYLOAD: 210 kg

- MAX. WORKING RANGE: 2,702 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 1,080 kg

- POWER SUPPLY: 3 kVA

- S AXIS: 120 °/s

- L AXIS: 97 °/s

- U AXIS: 113 °/s

- R AXIS: 145 °/s

- B AXIS: 145 °/s

- T AXIS: 220 °/s

- MOUNTING OPTIONS: Floor

SP235: Spot Welding Robot with High Payload

-

The MOTOMAN SP235 is a powerful spot welding and handling robot with a payload of 235 kg (including C-adapter). It is suitable for a wide range of common spot-welding guns and technologies, especially also for servo-controlled welding guns with robot-assisted gun alignment.

Its slim design does not require a mechanical counterbalance balancer and allows low moving masses as well as higher accelerations and

speeds. The stable wrist is particularly suitable for small and fast positioning movements, as are common in spot welding applications.The MOTOMAN SP235 is controlled by the compact and powerful MOTOMAN YRC1000 controller and features the latest Yaskawa Sigma7 servo drive technology, is state-of-the-art in terms of dynamics and energy efficiency, and enables outstanding cycle times.

- Versatile application possibilities

- High payload & small footprint

- High repeatability

- High energy efficiency

- NUMBER OF AXES: 6

- PAYLOAD: 235 kg

- MAX. WORKING RANGE: 2,710 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 1,345 kg

- POWER SUPPLY: 5 kVA

- S AXIS: 100 °/s

- L AXIS: 90 °/s

- U AXIS: 97 °/s

- R AXIS: 120 °/s

- B AXIS: 120 °/s

- T AXIS: 190 °/s

- MOUNTING OPTIONS:

Floor

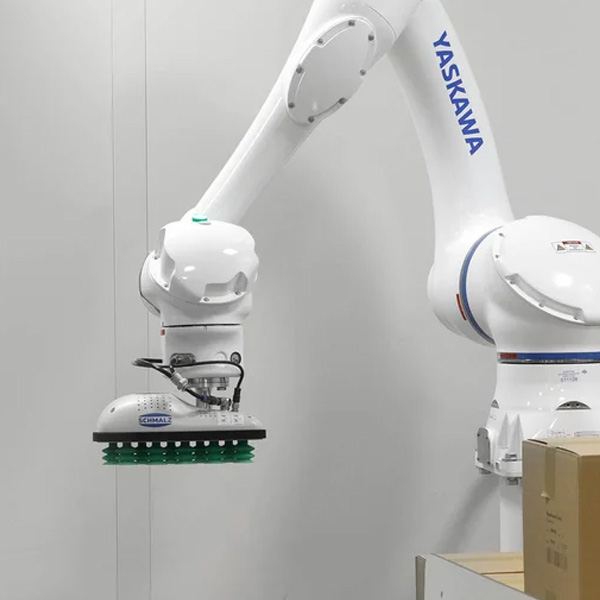

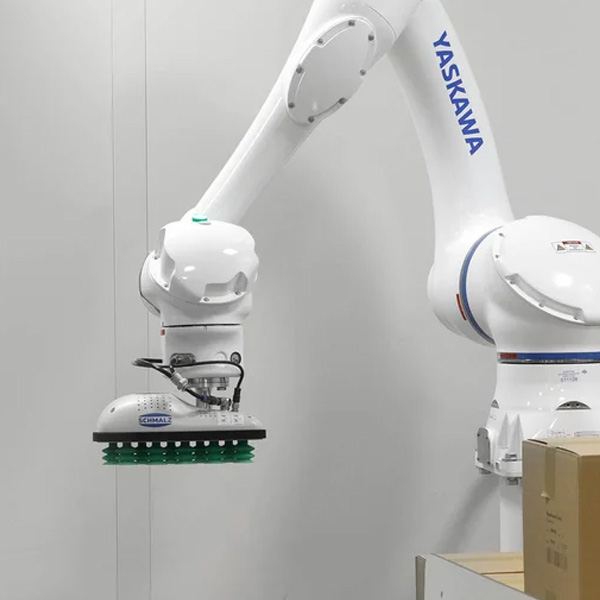

Palletizing and Depalletizing with Motoman Robots

- Palletizing is the act of stacking products onto a wooden (or plastic) shipping pallet for transport. Depalletizing is the unloading of these products at the destination. Palletizing is a relatively simple application for a robot to accomplish, as it involves minimal variation. Depalletizing is more complex and typically involves machine vision and sophisticated end effectors.

Yaskawa Motoman offers manufacturers a wide range of robotic solutions for palletizing and depalletizing. When using flexible robotics with 2D and 3D vision systems, specialized software and tooling enable you to customize your shipping and receiving without sacrificing speed and accuracy. Palletizing Robots - PL Series

- The versatile and powerful MOTOMAN PL robots provide high performance in box palletising, case palletising and many further logistical tasks for end-of-line or distribution center automation.

Offering extensive reaches this robots also enable high palletizing loads.

The interal wiring from the base to the U-axis maximizes system reliability.

PL80: Slim & flexible 5-axis Palletizing Robot

-

The MOTOMAN PL80 robot easily palletizes loads weighing up to 80 kg and has enormous axis speeds to ensure high palletizing cycles. Thanks to its kinematics, the small palletizing and handling robot of the Motoman PL series is ideally suited for box, carton and pack palletizing, for example in the growing logistics and e-commerce market. Very high palletizing cycles are required here. The MOTOMAN PL80 meets these requirements with over 800 cycles per hour.

Furthermore, the MOTOMAN PL80 also impresses with its low overall height, slim design and small footprint, in areas of application where space is often at a premium. Despite its very compact and slim design, the manipulator has sufficient horizontal and vertical reach for versatile applications, for example in end-of-line palletizing.

- NUMBER OF AXES: 5

- PAYLOAD: 80 kg

- MAX. WORKING RANGE: 2,061 mm

- REPEATABILITY: 0.03 mm

- WEIGHT: 565 kg

- POWER SUPPLY: 4.5 kVA

- S AXIS: 180 °/s

- L AXIS: 180 °/s

- U AXIS: 180 °/s

- B AXIS: 180 °/s

- T AXIS: 500 °/s

- MOUNTING OPTIONS: Floor

PL190-100: High Performance Palletizing & Handling

-

With over 2000 cycles per hour, the fast and powerful 4-axis MOTOMAN PL190-100 robot offers top performance for box, carton and bag palletizing for end-of-line packaging and logistics applications.

The optimized kinematic structure of this robot provides better stability and higher max. payload capacity of 100 kg.

The superior working range with a maximum reach of 3,159 mm and an achievable stacking height of over 2,600 mm is perfect for all kinds of palletizing tasks.

NUMBER OF AXES: 4

PAYLOAD: 100 kg

MAX. WORKING RANGE: 3,159 mm

REPEATABILITY: 0.05 mm

WEIGHT: 1,680 kg

POWER SUPPLY: 9.5 kVA

S AXIS: 140 °/s

L AXIS: 145 °/s

U AXIS: 145 °/s

T AXIS: 420 °/s

MOUNTING OPTIONS: Floor

PL190: High Performance Palletizing & Handling

-

With over 1700 cycles per hour, the fast and powerful 4-axis MOTOMAN PL190 robot offers top performance for box, carton and bag palletizing for end-of-line packaging and logistics applications.

The optimized kinematic structure of this robot provides even better stability and higher max. payload capacity of 190 kg compared to the predecessor model.

The superior working range with a maximum reach of 3,159 mm and an achievable stacking height of over 2,600 mm is perfect for all kinds of palletizing tasks.

- NUMBER OF AXES: 4

- PAYLOAD: 190 kg

- MAX. WORKING RANGE: 3,159 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 1,680 kg

- POWER SUPPLY: 9.5 kVA

- S AXIS: 140 °/s

- L AXIS: 145 °/s

- U AXIS: 145 °/s

- T AXIS: 420 °/s

- MOUNTING OPTIONS: Floor

PL320

-

With over 1400 cycles per hour, the fast and powerful 4-axis MOTOMAN PL320 robot offers top performance for box, carton and bag palletizing for end-of-line packaging and logistics applications.

The optimized kinematic structure of this robot provides even better stability and higher max. payload capacity of 320 kg compared to the predecessor model.

The superior working range with a maximum reach of 3,159 mm and an achievable stacking height of over 2,600 mm is perfect for all kinds of palletizing tasks.

- PAYLOAD: 320 kg

- MAX. WORKING RANGE: 3,159 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 1,680 kg

- POWER SUPPLY: 9.5 kVA

- S AXIS: 120 °/s

- L AXIS: 110 °/s

- U AXIS: 100 °/s

- T AXIS: 300 °/s

- MOUNTING OPTIONS: Floor

PL500: Palletizing / Depalletizing Robot for Heavy Loads up to 500 kg

-

The versatile and powerful 4-axis MOTOMAN PL500 offers top performance in palletizing and depalletizing applications and many other logistical applications for end-of-line packaging and automation solutions in distribution centers.

With its impressive 500kg payload capability, this robot is capable to handle large stones and machine parts or complete product layers or even complete loaded pallets.

- NUMBER OF AXES: 4

- PAYLOAD: 500 kg

- MAX. WORKING RANGE: 3,159 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 2,390 kg

- POWER SUPPLY: 8 kVA

- S AXIS: 85 °/s

- L AXIS: 85 °/s

- U AXIS: 85 °/s

- T AXIS: 195 °/s

- MOUNTING OPTIONS: Floor

PL800: Powerful Palletizing & Handling

-

The MOTOMAN PL800 is the most powerful 4-axis robot of the PL-series with a payload of 800 kg. This palletizer offers high performance for box, carton and pack palletizing in versatile end-of-line packaging and logistics applications.

Its large working range with a maximum reach of 3159 mm and an achievable stacking height of over 2624 mm allows versatile use across all palletizing applications.

- NUMBER OF AXES: 4

- PAYLOAD: 800 kg

- MAX. WORKING RANGE: 3,159 mm

- REPEATABILITY: 0.05 mm

- WEIGHT: 2,560 kg

- POWER SUPPLY: 8 kVA

- S AXIS: 65 °/s

- L AXIS: 65 °/s

- U AXIS: 65 °/s

- T AXIS: 125 °/s

- MOUNTING OPTIONS: Floor

Mounting & Handling & Packaging Robots - SG Series

-

With their high performance, SG Series SCARA robots enable extremely fast and precise operation for small part pick & place and part sortation. SG Series robots are easily deployable as production needs change.

SG400: High speed SCARA robot with 400 mm reach

- The robust MOTOMAN SG400 scara-robot features a wide motion range of 400 mm due to its compact design.

It has a maximum payload of 3 kg and is particularly suitable for application when high speed and accuracy is required, for example picking and packing, dispensing and feeding.

Technical Details- Number of axes 4

- Payload 3 kg

- Max working range 400 mm

- Repeatability 0.01 mm

- Weight 14kg

- Power supply 1 kVA

- S Axis 740 °/sec

- L Axis 800 °/sec

- U Axis 1200 °/sec

- R Axis 3000 °/sec

- Mounting Options Floor

SG650

- The robust MOTOMAN SG650 scara-robot features a wide motion range of 650 mm due to its compact design.

It has a maximum payload of 6 kg and is particularly suitable for application when high speed and accuracy is required, for example picking and packing, dispensing and feeding.

Technical Details- Number of axes 4

- Payload 6 kg

- Max working range 650 mm

- Repeatability 0.01 mm

- Weight 19 kg

- Power supply 1 kVA

- S Axis 450 °/sec

- L Axis 730 °/sec

- U Axis 1300 °/sec

- R Axis 2500 °/sec

- Mounting Options Floor

Mounting & Handling & Packaging Robots - MPP Series

- The MOTOMAN MPP 4-axis high-speed robot with a parallel kinematic system combines the speed of the Delta design with a high payload capacity and a large working envelope. This robot was developed for order picking, high-speed picking and other handling applications and is primarily used in the food and solar industries.

The MPP models feature a maximum payload of 3 kg and a working envelope of 1,300 mm

Due to the high torque of the fourth axis, known as the wrist axis, the MOTOMAN MPP models are impressive because of their ability to move at unprecedented speeds.

MPP3H

- The MOTOMAN MPP3H has a maximum payload of 3 kg and a working envelope of 1300 mm. ISO 5 at 50% and 100% speed.

Technical Details- Number of axes 4

- Payload 3 kg

- Max working range 1300 mm

- Repeatability 0.01 mm

- Weight 115 kg

- Power supply 1.5 kVA

- Mounting Options Floor

MPP3S

- The MOTOMAN MPP3S high-speed robot features a payload of 3 kg, a reach of 800 mm and 185 cycles per minute. ISO 4 at 50% speed, ISO 5 at 100% speed.

Technical Details- Number of axes 4

- Payload 3 kg

- Max working range 800 mm

- Repeatability 0.01 mm

- Weight 95 kg

- Power supply 1.5 kVA

- Mounting Options Ceiling

Mounting & Handling & Packaging Robots - MPK Series

- The MOTOMAN MPK high-speed robot provides superior performance for food handling, order picking, packaging and other high-speed handling applications—especially in environments where cleanliness and hygiene are extremely important.

The MPK models have payloads ranging from 2 kg to 5 kg and working envelopes from 900 mm to 1,893 mm.

Some models feature the IP67 code and are also wash-down ready.

MPK2F

- The MOTOMAN MPK2F 5-axis robot, with a payload of 2 kg and a reach of 900 mm, increases productivity by up to 133 picks per minute for superior performance in food handling, order picking and packaging applications. (IP67 protection code)

Technical Details- Number of axes 5

- Payload 2 kg

- Max working range 900 mm

- Repeatability 0.05 mm

- Weight 72 kg

- Power supply 2 kVA

- S Axis 320 °/sec

- L Axis 330 °/sec

- U Axis 330 °/sec

- B Axis 380 °/sec

- T Axis 2,000 °/sec

- Mounting Options Ceiling, Wall, Floor

MPK2F-5

- The MOTOMAN MPK2F-5 5-axis robot has a payload of 5 kg and a reach of 900 mm for superior performance in food handling, order picking and packaging applications. (IP67 protection code)

Technical Details- Number of axes 5

- Payload 5 kg

- Max working range 900 mm

- Repeatability 0.5 mm

- Weight 72 kg

- Power supply 1.5 kVA

- S Axis 320 °/sec

- L Axis 330 °/sec

- U Axis 330 °/sec

- B Axis 380 °/sec

- T Axis 2,000 °/sec

- Mounting Options Ceiling, Wall, Floor

Mounting & Handling & Packaging Robots - GP Series

- The Motoman GP series are compact and high speed handling robots which provide payloads of 7 to 600 kg.

Easy set-up and maintenance and a wrist structure with great environment resistance improve efficiency in installation, operation and maintenance of equipment.

GP4: Small and agile 6-axis Handling Robot with 4 kg Payload

-

The agile MOTOMAN GP4 is the smallest 6-axis robot in Yaskawa’s GP-series model range and offers high performance for a wide range of applications, such as flexible handling, machine tending and assembly applications, with axis speeds of up to 1000/s and a payload of up to 4 kg.

Providing an outstanding repeatability of ±0.01 mm, it is ideally suited for use in the electronics sector as well as for high precision assembly and quality testing applications.

The high IP67 protection class allows it to be used for CNC machine tending even under harsh environmental conditions, and it’s small footprint and compact design allows installation even in the tightest spaces.

- NUMBER OF AXES: 6

- PAYLOAD: 4 kg

- MAX. WORKING RANGE: 550 mm

- REPEATABILITY: 0.01 mm

- WEIGHT: 28 kg

- POWER SUPPLY: 1 kVA

- S AXIS: 465 °/s

- L AXIS: 465 °/s

- U AXIS: 525 °/s

- R AXIS: 565 °/s

- B AXIS: 565 °/s

- T AXIS: 1,000 °/s

- MOUNTING OPTIONS: Ceiling, Wall, Floor

GP4 FGG

-

The MOTOMAN GP4 FGG is a compact and agile 6-axis robot with 4 kg payload, 550 mm reach and outstanding repeatability of +/- 0.01 mm.

Due to latest Sigma-7 Servo Technology, the MOTOMAN GP4 FGG provides excellent axis speeds and accelerations. Specifications like high IP65/67 (dust/liquid proof) protection rating, food grade grease lubrication in all joints, and a a special drip proof coating allows the robot to be used in certain food related applications.

It’s small footprint and compact design allows installation even in the tightest spaces.

- NUMBER OF AXES: 6

- PAYLOAD: 4 kg

- MAX. WORKING RANGE: 550 mm

- REPEATABILITY: 0.01 mm

- WEIGHT: 28 kg

- POWER SUPPLY: 1 kVA

- S AXIS: 465 °/s

- L AXIS: 465 °/s

- U AXIS: 525 °/s

- R AXIS: 565 °/s

- B AXIS: 565 °/s

- T AXIS: 1,000 °/s

- MOUNTING OPTIONS: Ceiling, Wall, Floor

GP7

- The MOTOMAN GP7 is a compact and high speed handling robot which provides a payload of 7 kg and protection class IP67 to operate in harsh environments.

Easy set-up and maintenance and a wrist structure with great environment resistance improve efficiency in installation, operation and maintenance of equipment.

Anti-Corrosive painting of the GP7 ACC allows the robot to be used in environments with corrosive atmosphere such as acids, alkali and vapors.- Number of axes 6

- Payload 7 kg

- Max working range 927 mm

- Repeatability 0.0´1 mm

- Weight 34 kg

- Power supply 1 kVA

- S Axis 375 °/sec

- L Axis 315 °/sec

- U Axis 410 °/sec

- R Axis 550 °/sec

- B Axis 550 °/sec

- T Axis 2,000 °/sec

- Mounting Options Ceiling, Wall, Floor

GP7 FGG

- The MOTOMAN GP7 FGG is a compact and high speed handling robot which provides a payload of 7 kg.

Food grade grease allows this robot to be used in food related applications in secondary and tertiary packaging.

Its drip proof design assures smooth disposal of a liquid on the robot surface.- Number of axes 6

- Payload 7 kg

- Max working range 927 mm

- Repeatability 0.01 mm

- Weight 34 kg

- Power supply 1 kVA

- S Axis 375 °/sec

- L Axis 315 °/sec

- U Axis 410 °/sec

- R Axis 550 °/sec

- B Axis 550 °/sec

- T Axis 2,000 °/sec

- Mounting Options Ceiling, Wall, Floor

GP8 FGG

- The MOTOMAN GP8 FGG is a compact and high speed handling robot which provides a payload of 8 kg.

Food grade grease allows this robot to be used in food related applications in secondary and tertiary packaging.

Its drip proof design assures smooth disposal of a liquid on the robot surface.

Technical Details- Number of axes 6

- Payload 8 kg

- Max working range 727 mm

- Repeatability 0.0´1 mm

- Weight 32 kg

- Power supply 1 kVA

- S Axis 455 °/sec

- L Axis 385 °/sec

- U Axis 520 °/sec

- R Axis 550 °/sec

- B Axis 550 °/sec

- Mounting Options Ceiling, Wall, Floor

GP8

-

The MOTOMAN GP8, one of our most successful robot models ever, is an extremely agile, compact and universal robot with 8 kg payload, 727 mm reach and superior repeatability of +/- 0.01 mm. Our customers appreciate the performance of the GP8 in all kind of handling, assembly, pick&place and quality testing applications.

High IP 67 rating (dust and liquid protection) is standard, allowing the robot to work in harsh environments. The optional anti-corrosive coating (ACC) of the GP8 protects the robot in corrosive atmosphere such as acids, alkali and vapors. A GP8 food grade grease version and CR5 cleanroom class version is also available.

- NUMBER OF AXES: 6

- PAYLOAD: 8 kg

- MAX. WORKING RANGE: 727 mm

- REPEATABILITY: 0.01 mm

- WEIGHT: 35 kg

- POWER SUPPLY: 1 kVA

- S AXIS: 455 °/s

- L AXIS: 385 °/s

- U AXIS: 520 °/s

- R AXIS: 550 °/s

- B AXIS: 550 °/s

- T AXIS: 1,000 °/s

- MOUNTING OPTIONS: Ceiling, Wall, Floor

GP8 FGG: Agile 6-Axis Robot for Food Handling Applications

-

The MOTOMAN GP8 FGG is a compact and high speed handling robot which provides a payload of 8 kg.

Food grade grease allows this robot to be used in food related applications in secondary and tertiary packaging.

Its drip proof design assures smooth disposal of a liquid on the robot surface.

- NUMBER OF AXES: 6

- PAYLOAD: 8 kg

- MAX. WORKING RANGE: 727 mm

- REPEATABILITY: 0.01 mm

- WEIGHT: 35 kg

- POWER SUPPLY: 1 kVA

- S AXIS: 455 °/s

- L AXIS: 385 °/s

- U AXIS: 520 °/s

- R AXIS: 550 °/s

- B AXIS: 550 °/s

- MOUNTING OPTIONS: Ceiling, Wall, Floor

GP8 FGG HS: Food handling in hygienic environments

-

he MOTOMAN GP8 FGG HS (Food Grade Grease Hygienic Surface) is a very fast and precise 6-axis industrial robot with a payload of up to 8 kg especially for the food industry. With a reach of 727 mm and a high repeatability of ± 0.01 mm, it is ideally suited for universal handling or packaging tasks. Its modern, smooth, slim and award-winning industrial design minimizes the space required at the installation site.

The MOTOMAN GP8 FGG HS is designed with the high IP67 protection class as standard, is equipped with food-grade grease for tasks in the food industry and has an easy-to-wash surface with special anti-corrosive coating for use under aggressive environmental conditions.

- Hygienic surface

- Optimized for food handling

- Low interference contours due to optimized design

- Fast and flexible

- NUMBER OF AXES: 6

- PAYLOAD: 8 kg

- MAX. WORKING RANGE: 727 mm

- REPEATABILITY: 0.01 mm

- WEIGHT: 35 kg

- POWER SUPPLY: 1 kVA

- S AXIS: 455 °/s

- L AXIS: 385 °/s

- U AXIS: 520 °/s

- R AXIS: 550 °/s

- B AXIS: 550 °/s

- T AXIS: 1,000 °/s

- MOUNTING OPTIONS: Ceiling, Wall, Floor

GP8L: Fast and compact handling robot with high reach

-

The MOTOMAN GP8L is a 6-axis general-purpose industrial robot providing 8 kg payload and a long reach of 1,636 mm.

With its slim design and compact, narrow wrist, it is particularly suitable for applications where space is at a premium, such as loading/unloading containers in packaging technology or logistics.

Automation around machine tools and injection molding machines can also be excellently implemented with this robot.

With numerous functions, interfaces and communication options of the YRC1000/YRC1000micro controllers, the MOTOMAN GP8L is open to a full range of different technologies, including modern sensor systems and image processing systems, which can be combined very well.

- NUMBER OF AXES: 6

- PAYLOAD: 8 kg

- MAX. WORKING RANGE: 1,636 mm

- REPEATABILITY: 0.02 mm

- WEIGHT: 155 kg

- POWER SUPPLY: 1.5 kVA

- S AXIS: 260 °/s

- L AXIS: 230 °/s

- U AXIS: 260 °/s

- R AXIS: 470 °/s

- B AXIS: 550 °/s

- T AXIS: 1,000 °/s

- MOUNTING OPTIONS: Ceiling, Wall, Floor

GP12

- The MOTOMAN GP12 is a compact and flexible handling robot which provides a payload of 12 kg.

Easy set-up and maintenance and a wrist structure with great environment resistance improve efficiency in installation, operation and maintenance of equipment.

This robot is also available with protection class IP65/67 to operate in harsh environments.- Number of axes 6

- Payload 12 kg

- Max working range 1140 mm

- Repeatability 0.02 mm

- Weight 150 kg

- Power supply 1.5 kVA

- S Axis 260 °/sec

- L Axis 230 °/sec

- U Axis 260 °/sec

- R Axis 470 °/sec

- B Axis 470 °/sec

- T Axis 700 °/sec

- Mounting Options Ceiling, Wall, Floor

GP12 FGG

- The MOTOMAN GP12 FGG is a compact and flexible handling robot which provides a payload of 12 kg.

Food grade grease allows this robot to be used in food related applications in secondary and tertiary packaging.

Its drip proof design assures smooth disposal of a liquid on the robots surface.- Number of axes 6

- Payload 12 kg

- Max working range 1140 mm

- Repeatability 0.02 mm

- Weight 155 kg

- Power supply 1.5 kVA

- S Axis 260 °/sec

- L Axis 230 °/sec

- U Axis 260 °/sec

- R Axis 470 °/sec

- B Axis 470 °/sec

- T Axis 700 °/sec

- Mounting Options Ceiling, Wall, Floor

GP25-12

- The flexible MOTOMAN GP25-12 handling robot provides a payload of 12 kg and a maximum reach of 2,010 mm.

- Number of axes 6

- Payload 12 kg

- Max working range 2,010 mm

- Repeatability 0.03 mm

- Weight 260 kg

- Power supply 2 kVA

- S Axis 210 °/sec

- L Axis 210 °/sec

- U Axis 220 °/sec

- R Axis 435 °/sec

- B Axis 700 °/sec

- T Axis 700 °/sec

- Mounting Options Ceiling, Wall, Floor

GP20: Fast & precise handling robot with 20 kg payload

-

The MOTOMAN GP20 is a fast and precise 6-axis industrial robot with a payload of up to 20 kg.

With a reach of 1,802 mm and a high repeatability of ± 0.02 mm, it can be used for a variety of applications, such as machine tending, material handling, packaging and assembly of small to medium-sized workpieces.

Its robust, modern and slim industrial design enables high moment of inertia und very low wrist vibration.

With numerous functions of the MOTOMAN YRC1000 controller, the MOTOMAN GP20 has a wide range of possible applications.

- NUMBER OF AXES: 6

- PAYLOAD: 20 kg

- MAX. WORKING RANGE: 1,802 mm

- REPEATABILITY: 0.02 mm

- WEIGHT: 250 kg

- POWER SUPPLY: 2 kVA

- S AXIS: 210 °/s

- L AXIS: 210 °/s

- U AXIS: 265 °/s

- R AXIS: 420 °/s

- B AXIS: 420 °/s

- T AXIS: 720 °/s

- MOUNTING OPTIONS: Ceiling, Wall, Floor

GP20HL

-

The six-axis MOTOMAN GP20HL robot combines a unique long reach of 3.124 mm with a payload capability of 20kg, by keeping an excellent repeatability precision of less than +/- 0.07 mm.

The GP20HL combines precision, world-leading path performance, speed and functionality. Equipped with latest generation Sigma-7 Servo drive & control technology, the GP20HL achieves best cycle times avoiding vibrations.

Typical applications for this robot include handling of very large and flat workpieces, interior car body sealing or the spray application of glue on carpets or insulating material.

- NUMBER OF AXES: 6

- PAYLOAD: 20 kg

- MAX. WORKING RANGE: 3,124 mm

- REPEATABILITY: 0.07 mm

- WEIGHT: 560 kg

- POWER SUPPLY: 4 kVA

- S AXIS: 180 °/s

- L AXIS: 180 °/s

- U AXIS: 180 °/s

- R AXIS: 400 °/s

- B AXIS: 430 °/s

- T AXIS: 630 °/s

- MOUNTING OPTIONS: Ceiling, Wall, Floor

GP25

- The MOTOMAN GP25 is a compact and flexible handling robot which provides a payload of 25 kg.

Easy set-up and maintenance and a wrist structure with great environment resistance improve efficiency in installation, operation and maintenance of equipment.

This robot is also available with protection class IP65/67 to operate in harsh environments.- Number of axes 6

- Payload 20 kg

- Max working range 3,124 mm

- Repeatability 0.07 mm

- Weight 560 kg

- Power supply 4 kVA

- S Axis 180 °/sec

- L Axis 180 °/sec

- U Axis 180 °/sec

- R Axis 400 °/sec

- B Axis 430 °/sec

- T Axis 630 °/sec

- Mounting Options Ceiling, Wall, Floor

GP25 FGG

- The MOTOMAN GP25 FGG is a compact and flexible handling robot which provides a payload of 25 kg.

Food grade grease allows this robot to be used in food-related applications in secondary and tertiary packaging.

Its drip-proof design assures smooth disposal of a liquid on the robot surface.- Number of axes 6

- Payload 25 kg

- Max working range 1730 mm

- Repeatability 0.02 mm

- Weight 265 kg

- Power supply 2 kVA

- S Axis 210 °/sec

- L Axis 210 °/sec

- U Axis 265 °/sec

- R Axis 420 °/sec

- B Axis 420 °/sec

- T Axis 885 °/sec

- Mounting Options Ceiling, Wall, Floor

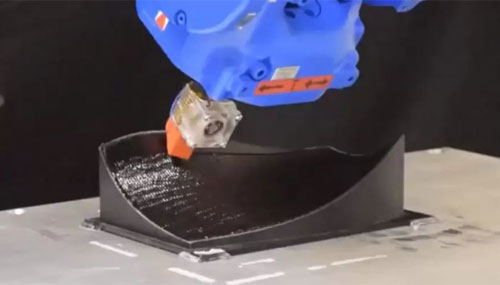

GP35L: Multi-Purpose Handling Robot with 2.5 m Reach

-

The MOTOMAN GP35L is a highly versatile 6-axis industrial robot with a 35 kg payload, extended reach (2.538 mm), and outstanding repeatability of +/- 0.07 mm.

The GP35L robot is offering a perfectly tuned payload/speed/wrist allowable moment combination, for impressive speed and acceleration performance. The small footprint, slim arm design allows for minimum installation space and minimize interference with peripheral devices.

A version with high IP65/67 (dust & liquid protection) is available, for operation in harsh environments.

The GP35L is perfect for a wide range of applications, perfect for machine tending, material handling, material removal, assembly, additive manufacturing or dispensing.

- Number of axes 6

- Payload 35 kg

- Max working range 2538 mm

- Repeatability 0.07 mm

- Weight 600 kg

- Power supply 4 kVA

- S Axis 180 °/sec

- L Axis 140 °/sec

- U Axis 178 °/sec

- R Axis 250 °/sec

- B Axis 250 °/sec

- T Axis 360 °/sec

- Mounting Options Ceiling, Wall, Floor

GP50 FGG

- The powerful and flexible MOTOMAN GP50 FGG handling robot provides a payload of 50 kg.

Food grade grease allows this robot to be used in food-related applications in secondary and tertiary packaging.

Its drip-proof design assures smooth disposal of a liquid on the robot surface.- Number of axes 6

- Payload 50 kg

- Max working range 2061 mm

- Repeatability 0.03 mm

- Weight 585 kg

- Power supply 4 kVA

- S Axis 180 °/sec

- L Axis 178 °/sec

- U Axis 178 °/sec

- R Axis 470 °/sec

- B Axis 150 °/sec

- T Axis 200 °/sec

- Mounting Options Ceiling, Wall, Floor

GP50: Multi-Purpose Handling robot with 50 kg Payload

-

The MOTOMAN GP50 is a highly versatile 6-axis industrial robot with 50 kg payload, 2.061 mm reach, and an outstanding repeatability of +/- 0.03 mm.

The GP50 robot is offering a perfectly tuned payload / speed / wrist allowable moment combination, for impressive speed and acceleration performance. The small footprint, slim arm design allows for minimum installation space and minimizes interference with peripheral devices.

A version with high IP65/67 (dust & liquid protection) is available, for operation in harsh environments.

The GP50 is perfect for a wide range of applications, including machine tending, material handling, material removal, assembly, additive manufacturing, dispensing and grinding/polishing.

- NUMBER OF AXES: 6

- PAYLOAD: 50 kg

- MAX. WORKING RANGE: 2,061 mm

- REPEATABILITY: 0.03 mm

- WEIGHT: 570 kg

- POWER SUPPLY: 4 kVA

- S AXIS: 180 °/s

- L AXIS: 187 °/s

- U AXIS: 187 °/s

- R AXIS: 250 °/s

- B AXIS: 250 °/s

- T AXIS: 360 °/s

- MOUNTING OPTIONS: Ceiling, Wall, Floor

GP50 FGG: 6-axis Robot with 50 kg Payload for the Food Industry

-

The GP50 FGG is a highly versatile 6-axis robot with 50 kg payload, 2.051 mm reach and outstanding repeatability of +/- 0.03 mm. Specifications like high IP65/67 (dust/liquid proof) protection rating, food grade grease lubrication in all joints, and a a special drip proof coating allows the robot to be used in certain food related applications.

High transfer rates are achievable with the fast and efficient GP50 FGG robot, which offers a perfectly tuned combination of payload / speed / wrist allowable moment. Designed with the latest YASKAWA Sigma7-Servo Motor Generation, the GP50 FGG benefits from improved acceleration/deceleration control. The small footprint and slim arm design allows for minimum installation space and minimizes interference with peripheral devices.

NUMBER OF AXES: 6

PAYLOAD: 50 kg

MAX. WORKING RANGE: 2,061 mm

REPEATABILITY: 0.03 mm

WEIGHT: 585 kg

POWER SUPPLY: 4 kVA

S AXIS: 180 °/s

L AXIS: 178 °/s

U AXIS: 178 °/s

R AXIS: 150 °/s

B AXIS: 150 °/s

T AXIS: 200 °/s

MOUNTING OPTIONS: Ceiling, Wall, Floor

GP88: Multi-Purpose Handling Robot with 88 kg Payload

-

The GP88 is a compact 6-axis industrial robot with 88 kg payload, 2236 mm reach and excellent repeatability of +/- 0.03 mm. Equipped to handle high payloads for heavy part processing, the powerful six-axis GP88 robot increases productivity for a wide selection of tasks. While high moment and inertia ratings support large and heavy applications, exceptionally quick axis speeds and acceleration capabilities reduce cycle time. The compact design enables high-density robot placement in workcells. Pre-wired with sognal and pneumatic lines, the high-speed GP88 offers simple installation, easy operation and minimal maintenance for increased production output.

A version with high IP67 (sust and liquid proof) protection class is available for jobs in harsh environments.

The GP88 is perfect for a wide range of applications, including machine tending, material handling, material removal, assembly, additive manufacturing, dispensing and grinding/polishing.

- NUMBER OF AXES: 6

- PAYLOAD: 88 kg

- MAX. WORKING RANGE: 2,236 mm

- REPEATABILITY: 0.03 mm

- WEIGHT: 630 kg

- POWER SUPPLY: 4 kVA

- S AXIS: 170 °/s

- L AXIS: 140 °/s

- U AXIS: 160 °/s

- R AXIS: 230 °/s

- B AXIS: 230 °/s

- T AXIS: 350 °/s

- MOUNTING OPTIONS: Ceiling, Wall, Floor

GP110: Multi-Purpose Handling Robot with 88 kg Payload

-

The GP110 is a compact 6-axis industrial robot with 110 kg payload, 2236 mm reach and excellent repeatability of +/- 0.03 mm. Equipped to handle high payloads for heavy part processing, the powerful six-axis GP110 robot increases productivity for a wide selection of tasks. While high moment and inertia ratings support large and heavy applications, exceptionally quick axis speeds and acceleration capabilities reduce cycle time. The compact design enables high-density robot placement in workcells. Pre-wired with sognal and pneumatic lines, the high-speed GP110 offers simple installation, easy operation and minimal maintenance for increased production output.

A version with high IP67 (sust and liquid proof) protection class is available for jobs in harsh environments.

The GP110 is perfect for a wide range of applications, including machine tending, material handling, material removal, assembly, additive manufacturing, dispensing and grinding/polishing.

NUMBER OF AXES: 6

PAYLOAD: 110 kg

MAX. WORKING RANGE: 2,236 mm

REPEATABILITY: 0.03 mm

WEIGHT: 660 kg

POWER SUPPLY: 5 kVA

S AXIS: 140 °/s

L AXIS: 110 °/s

U AXIS: 130 °/s

R AXIS: 175 °/s

B AXIS: 175 °/s

T AXIS: 255 °/s

MOUNTING OPTIONS: Floor

GP180-120: Long Reach Handling Robot woth 120 kg Payload

-

The MOTOMAN GP180-120 handling robot provides a very long reach of more than 3 meters, a max. payload of 120 kg and an excellent repeatability precision of +/- 0,05 mm.

The GP180-120 is a long-arm version of the GP180, providing fast and accurate performance to boost productivity for high-payload handling applications. Featuring a wide work envelope, this robot uses a streamlined upper arm for easy access to parts in confined spaces. While the wide wrist motion range reduces interference with fixtures, the reduced interference design enables close proximity placement of robots. A heavy mechanical balancer is not required any more, and latest high performance Sigma7 servo drive technology is leading to fast axis speeds and powerful acceleration. A wrist with high moment and inertia ratings enables the GP180-120 robot to efficiently handle larger and heavier payloads for superior performance. In combination with a robot track, this robot is a perfect solution to feed large panels between different machines or workcells.

The GP180-120 is perfect for a wide variety of applications, such as Material Handling of larger parts/panels, (Remote) Laser Welding, Spot Welding, Press Tending.

- Number of axes 6

- Payload 120 kg

- Max working range 3058 mm

- Repeatability 0.05 mm

- Weight 1090 kg

- Power supply5 kVA

- S Axis 125 °/sec

- L Axis 115 °/sec

- U Axis 125 °/sec

- R Axis 182 °/sec

- B Axis 175 °/sec

- T Axis 265 °/sec

- Mounting Options Floor

GP120RL: Long-arm shelf-mounted robot with 4m reach

-

The flexible, shelf-mounted MOTOMAN GP120RL robot provides a superb reach of 4 meters (!), a payload of 120 kg and an outstanding repeatability of better than +/- 0.2 mm. A streamlined upper arm provides easy access to parts in confined spaces. As being a shelf-type robot, the motion range is extended for working below the robot base level, allowing to the robot to be installed on a raised steel structure to save floor space.

The MOTOMAN GP120RL is the ideal candidate for (multi) machine tending from above, press brake tending and loading/unloading long or flat panels to machines with large loading areas. In many applications, this robot helps avoiding installation of robot tracks or gantries.

Our customers are preferring this robot for Machine Tending (large CNC and Injection Moulding Machines), Wood & Furniture Handling and Packaging, Press Tending and Handling Applications in Automotive and Agricultural or Construction Machinery.

- Number of axes 6

- Payload 120 kg

- Max working range 4004 mm

- Repeatability 0.2 mm

- Weight 1830 kg

- Power supply 2 kVA

- S Axis 90 °/sec

- L Axis 85 °/sec

- U Axis 85 °/sec

- R Axis 175 °/sec

- B Axis 150 °/sec

- T Axis 240 °/sec

- Mounting Options Shelf-Mounted

GP165R: Shelf mounted robot with high payload

-

The flexible, shelf-mounted MOTOMAN GP165R robot provides extended reach of 3.134 mm, a payload of 165 kg and an outstanding repeatability of better than +/- 0.05 mm. A streamlined upper arm provides easy access to parts in confined spaces. As being a shelf-type robot, the motion range is extended for working below the robot base level, allowing to the robot to be installed on a raised steel structure to save floor space. Latest Sigma7 Servo Motor technology and high inertia wrist allows fast axis speed and acceleration to decrease cycle time and optimize production output.

The MOTOMAN GP165R is well suited for spot welding, handling and (multi) machine tending.

- Number of axes 6

- Payload 165 kg

- Max working range 3143 mm

- Repeatability 0.05 mm

- Weight 1760 kg

- Power supply 5 kVA

- S Axis 105 °/sec

- L Axis 105 °/sec

- U Axis 105 °/sec

- R Axis 175 °/sec

- B Axis 150 °/sec

- T Axis 240 °/sec

- Mounting Options Shelf-Mounted

GP180: Multi-Purpose Handling Robot with 180 kg Payload

-

The MOTOMAN GP180 handling robot provides a payload of 180 kg and a maximum reach of 2,702 mm, combined with an excellent repeatability precision of +/- 0,05 mm.

This six-axis GP180 robot provides fast and accurate performance to boost productivity for high-payload handling applications. Featuring a wide work envelope, this robot uses a streamlined upper arm for easy access to parts in confined spaces. While the wide wrist motion range reduces interference with fixtures, the reduced interference design enables close proximity placement of robots. A heavy mechanical balancer is not required any more, and latest high performance Sigma7 servo drive technology is leading to fast axis speeds and powerful acceleration. A wrist with high moment and inertia ratings enables the GP180 robot to efficiently handle larger and heavier payloads for superior performance.

For use in harsh environments, a GP180 version with high IP65/67 Protection (dust & liquid proof) is available.

The GP180 is perfect for a big variety of applications, such as Material Handling, (Remote) Laser Welding, Spot Welding, Press Tending and Material Cutting/Trimming.

- Number of axes 6

- Payload 180 kg

- Max working range 2702 mm

- Repeatability 0.05 mm

- Weight 1020 kg

- Power supply 5 kVA

- S Axis 125 °/sec

- L Axis 115 °/sec

- U Axis 125 °/sec

- R Axis 182 °/sec

- B Axis 175 °/sec

- T Axis 265 °/sec

- Mounting Options Floor

GP200R: Shelf mounted robot with high payload

-

The flexible, shelf-mounted MOTOMAN GP200R robot provides an extended reach of 3.140 mm, a payload of 200 kg and an outstanding repeatability of better than +/- 0.05 mm. A streamlined upper arm provides easy access to parts in confined spaces. As being a shelf-type robot, the motion range is extended for working below the robot base level, allowing to the robot to be installed on a raised steel structure to save floor space. The latest Sigma7 Servo Motor technology and high inertia wrist allows fast axis speed and acceleration to decrease cycle time and optimize production output.

The MOTOMAN GP200R is well suited for heavy spot welding guns and grippers in spot welding, press transfer, material handling and machine tending.

- Number of axes 6

- Payload 12 kg

- Max working range 1140 mm

- Repeatability 0.02 mm

- Weight 155 kg

- Power supply 1.5 kVA

- S Axis 90 °/sec

- L Axis 85 °/sec

- U Axis 85 °/sec

- R Axis 120 °/sec

- B Axis 120 °/sec

- T Axis 190 °/sec

- Mounting Options Shelf-Mounted

GP215

-

The MOTOMAN GP215 handling robot provides a payload of 215 kg and a maximum reach of 2,912 mm, combined with an excellent repeatability precision of +/- 0,05 mm.

This six-axis GP215 robot provides fast and accurate performance to boost productivity for high-payload handling applications. Featuring a wide work envelope, this robot uses a streamlined upper arm for easy access to parts in confined spaces. While the wide wrist motion range reduces interference with fixtures, the reduced interference design enables close proximity placement of robots. Latest generation high performance Sigma7 servo drive technology is leading to fast axis speeds and powerful acceleration. A high moment and inertia wrist enables the GP215 robot to efficiently handle larger and heavier payloads for superior performance.

The GP215 is perfect for a big variety of applications, such as Material Handling, (Remote) Laser Welding, Spot Welding, Press Tending and (due to it's excellent mechanical stiffness) also for Material Cutting/Trimming.

- Number of axes 6

- Payload 215 kg

- Max working range 2912 mm

- Repeatability 0.05 mm

- Weight 1340 kg

- Power supply 5 kVA

- S Axis 100 °/sec

- L Axis 90 °/sec

- U Axis 97 °/sec

- R Axis 120 °/sec

- B Axis 120 °/sec

- T Axis 190 °/sec

- Mounting Options Floor

GP225: Multi-Purpose Handling Robot with 225 kg Payload

-

The MOTOMAN GP225 handling robot provides a payload of 225 kg and a maximum reach of 2,702 mm, combined with an excellent repeatability precision of +/- 0,05 mm.

This six-axis GP225 robot provides fast and accurate performance to boost productivity for high-payload handling applications. Featuring a wide work envelope, this robot uses a streamlined upper arm for easy access to parts in confined spaces. While the wide wrist motion range reduces interference with fixtures, the reduced interference design enables close proximity placement of robots. A heavy mechanical balancer is not required any more, and latest high performance Sigma7 servo drive technology is leading to fast axis speeds and powerful acceleration. A wrist with high moment and inertia ratings enables the GP225 robot to efficiently handle larger and heavier payloads for superior performance.

For use in harsh environments, a GP225 version with high IP65/67 Protection (dust & liquid proof) is available.

The GP225 is perfect for a big variety of applications, such as Material Handling, (Remote) Laser Welding, Spot Welding, Press Tending and Material Cutting/Trimming.

- Number of axes 6

- Payload 225 kg

- Max working range 2702 mm

- Repeatability 0.05 mm

- Weight 1080 kg

- Power supply 5 kVA

- S Axis 120 °/sec

- L Axis 97 °/sec

- U Axis 115 °/sec

- R Axis 145 °/sec

- B Axis 145 °/sec

- T Axis 220 °/sec

- Mounting Options Floor

GP250: Multi-Purpose Handling Robot with 250 kg Payload

-

The MOTOMAN GP250 handling robot provides a payload of 250 kg and a maximum reach of 2,710 mm, combined with an excellent repeatability precision of +/- 0,05 mm.

This six-axis GP250 robot provides fast and accurate performance to boost productivity for heavy payload handling applications. Featuring a wide work envelope, this robot uses a streamlined upper arm for easy access to parts in confined spaces. While the wide wrist motion range reduces interference with fixtures, the reduced interference design enables close proximity placement of robots. The latest generation high-performance Sigma7 servo drive technology is leading to fast axis speeds and powerful acceleration. A high moment and inertia wrist enables the GP250 robot to efficiently handle larger and heavier payloads for superior performance.

The GP250 is perfect for a big variety of applications, such as Material Handling, (Remote) Laser Welding, Spot Welding, Press Tending and (due to its excellent mechanical stiffness) also for Material Cutting/Trimming.

- Number of axes 6

- Payload 250 kg

- Max working range 2,710 mm

- Repeatability 0.05 mm

- Weight 1,345 kg

- Power supply 5 kVA

- S Axis 100 °/sec

- L Axis 90 °/sec

- U Axis 97 °/sec

- R Axis 120 °/sec

- B Axis 470 °/sec

- T Axis 190 °/sec

- Mounting Options Floor

GP280

-

The MOTOMAN GP280 handling robot provides a high payload capability of 280 kg and a compact reach of 2,446 mm, combined with an excellent repeatability precision of +/- 0,05 mm.

This six-axis GP280 robot provides fast and accurate performance to boost productivity for high-payload handling applications. Featuring a wide work envelope, this robot uses a streamlined upper arm for easy access to parts in confined spaces. While the wide wrist motion range reduces interference with fixtures, the reduced interference design enables close proximity placement of robots. The latest generation high-performance Sigma7 servo drive technology is leading to fast axis speeds and powerful acceleration. A high moment and inertia wrist enables the GP280 robot to efficiently handle larger and heavier payloads for superior performance.

The GP280 is perfect for a big variety of applications, such as Material Handling, (Remote) Laser Welding, Spot Welding, Machine Tending and (due to its excellent mechanical stiffness) also for Material Cutting/Trimming, Roller Hemming or Friction Stir Welding.

The GP280 is often used for workpiece handling in "Jigless" Welding Application, where the robot replaces a fixture.

- Number of axes 6

- Payload 280 kg

- Max working range 2446 mm

- Repeatability 0.05 mm

- Weight 1300 kg

- Power supply 5 kVA

- S Axis 90 °/sec

- L Axis 80 °/sec

- U Axis 90 °/sec

- R Axis 115 °/sec

- B Axis 110 °/sec

- T Axis 190 °/sec

- Mounting Options Floor

GP400: Heavy Payload 6-Axis Robot

-

The powerful MOTOMAN GP400 handling robot provides an impressive payload of 400 kg and a maximum reach of 2,942 mm. Due to its parallel link design, the outstanding repeatability is better than +/- 0.1 mm.

Designed with extremely fast axis speeds and parallel-link construction to expertly perform heavy-payload tasks, the six-axis GP400 is ideal for heavy part handling, machine and press tending, as well as “jigless” applications. Engineered for simple installation, easy operation and minimal maintenance, this robot features a wide work envelope, along with high moment and inertia ratings for the accommodation of large, heavy parts.

A streamlined upper arm provides easy access to parts in tight spaces, and a reduced interference design allows the robot to be placed closer to workpieces and machines, optimizing floor space. Equipped with heavy-duty bearings for smooth arm rotation, the GP400 is a smart choice to fulfil a variety of heavy-payload needs.

- Number of axes 6

- Payload 400 kg

- Max working range 2942 mm

- Repeatability 0.01 mm

- Weight 2840 kg

- Power supply 7 kVA

- S Axis 102 °/sec

- L Axis 97 °/sec

- U Axis 97 °/sec

- R Axis 80 °/sec

- B Axis 80 °/sec

- T Axis 172 °/sec

- Mounting Options Floor

GP400R: Heavy-Payload Shelf Type Robot with 400 kg Payloas

-

The shelf-mounted MOTOMAN GP400R robot provides an impressive combination of 400 kg payload and 3.5 m reach, with an outstanding repeatability precision of better than +/- 0.1 mm. As being a shelf-type robot, the motion range is extended for working below the robot base level, allowing to the robot to be installed on a raised steel structure to save floor space.

Designed with extremely fast axis speeds and parallel-link construction to expertly perform heavy-payload tasks, the six-axis GP400R is ideal for heavy part handling, machine and press tending.

Engineered for simple installation, easy operation and minimal maintenance, this robot features a wide work envelope, along with high moment and inertia ratings for the accommodation of large, heavy parts. A streamlined upper arm provides easy access to parts in tight spaces, and a reduced interference design allows the robot to be placed closer to workpieces and machines, optimizing floorspace. Equipped with heavy-duty bearings for smooth arm rotation, the GP400R is a perfect choice to fulfill a variety of heavy-payload needs.

Our customers are preferring this robot for Machine Tending (large CNC and Injection Moulding Machines), Wood & Furniture Handling and Packaging, Press Tending and Handling Applications in Automotive and Agricultural or Construction Machinery.

- Number of axes 6

- Payload 400 kg

- Max working range 3158 mm

- Repeatability 0.1 mm

- Weight 3560 kg

- Power supply 7 kVA

- S Axis 80 °/sec

- L Axis 80 °/sec

- U Axis 80 °/sec

- R Axis 80 °/sec

- B Axis 80 °/sec

- T Axis 160 °/sec

- Mounting Options Shelf-Mounted

GP600: Heavy Payload 6-Axis Robot

-