- Offer Profile

- Okamoto Machine Tool Works

Ltd. Japan has been the world‘s leading manufacturer of high-quality

grinding machines and equipment since 1926.

The intense collaborations between Okamoto Machine Tool Works Ltd. Japan and Okamoto Machine Tool Europe GmbH guarantees the development

and manufacture of innovative grinding machines with the very highest precision. In our actions, we aspire to respond positively to

the market and make use of investments for future growth for the overall success of our company.

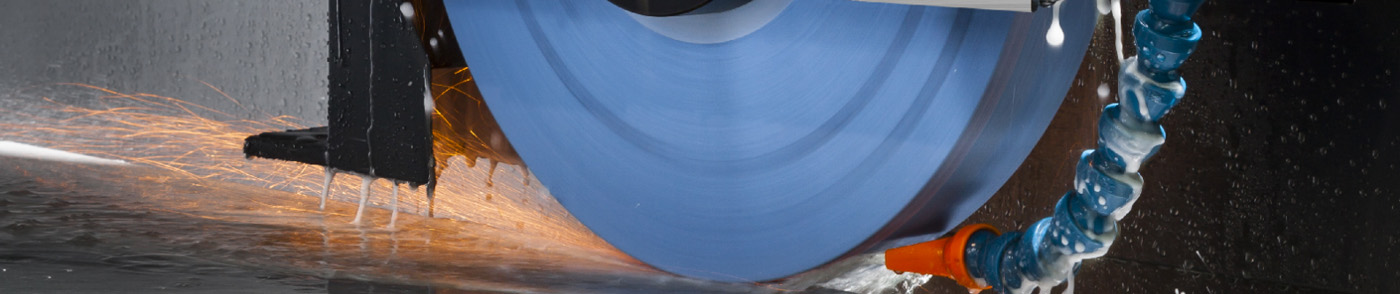

SURFACE GRINDING

SURFACE & PROFILE GRINDERS

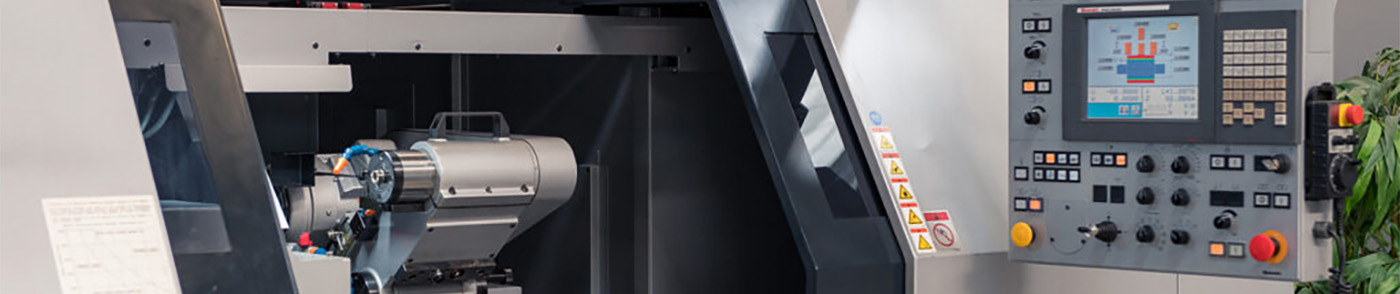

ACC 42SAIQ

-

Endless challenge to Zero

Simply the best CNC profile grinding machine developed from our long experience in the grinding machine market. The advantages are manifold: Compact Moving Saddle Design, Fanuc CNC Control with dialogue software, 1/10 Micron AC Servo Motors, Fully Automatie Grind Cycle, automatie profile wheel dressing with Compensation, for the purpose of long lifetime and maintenance free operation, oil lubrication with automatic lubrication is applied to the guide and slide way, combination of both scraped V-V slide way and low friction Turcite assure accurate grinding for life, all castings exhibit high static and dynamic stiffness and excellent damping qualities.

- Grinding wheel (2O5 x 13 x 31.75 mm)

- Grinding wheel adaptor for wheels

- Levelling screws and plates

- Necessary Tools

- Worklight

UPZ 52Li

-

Ultra Precision surface and profile grinding machine

This high speed grinding machine has a length capacity of 500 x 200mm width and is suitable for use in the toolroom or in a production environment. The stable design of the wheel head and slideways with linear guideways in both the table and cross slides guarantee the highest precision over a long time. The easy to use software in the machine control simplifies programming and increases production.

- Table drive via linear motor

- Workpiece measuring system

- CCD-Camera

- High speed reciprocation up to 500/min

- Temperature stabilised wheelhead

Additional equipment

- Elektro-permanent magnetic chuck 500 mm x 200 mm

- Paper band filter coolant system

- Mist collector

- 2-point rotary dresser

- Measuring system incl. CCD camera and software

UPZ 210 Li/LiII

-

Ultra Precision surface and profile grinding machine

With a machine weight of 5700 kg this machine offers the basis of a low vibration ultra precision profile grinding machine. High precision linear guideways and optional hydrostatic ways are paired with a linear motor drive for the table that allows a table oscillation speed of up to 250 reciprocations in each direction per minute. The machine is equipped with two independent wheel heads mounted on precision linear guideways positioned with linear motors. the twin wheel head can be utilised for roughing and finish grinding or for grinding both left and right sides of a profile in one operation. When combined with an optional CCD measuring camera, it is able to automatically measure and optionally compensate any eventual error to guarantee a perfect component in a single operation without operator intervention.

- CNC Fast Resiprocation grinding machine with linear motor drives

- Available in single spindle wheel head and double spindle wheel head variations

- Carbide grinding with 520 oscillations per minute

- Rough grinding, fine grinding, measuring, with automatic compensation in one loading

Additional equipment

- Coolant system

- Mist collector

- Temperature stabilization

- Cleaning cycle during measurement

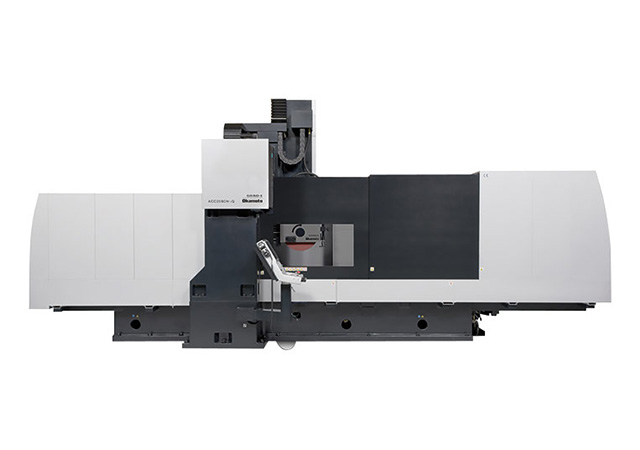

ACC CAIQ SERIES

-

Precision surface and profile grinding machine

With a grinding length of 600 – 1000 mm and a cross travel of 400 – 600 mm the Okamoto ACC-CAiQ Series is ideally suited for the toolroom. It features a high level of standard equipment to ensure easy handling, quick and precise small part production. The robust cast iron construction and double-V slideways in the table ensure long term precision. The intuitive operation of the controls simplifies usage and increases productivity considerably.

- Surface and profile grinding machine

- Easy-to-use Fanuc colour touch screen controller

- Moving column design

- Magnetic chuck sizes from 600 x 400 to 1000 x 600 mm

PSG CA3 SERIES

-

Precision surface grinding machine

With a grinding length of 600 – 1000 mm and a cross travel of 400 – 600mm the Okamoto PSG-CA3 is ideally suited for the toolroom. It features a high level of standard equipment to ensure easy handling, quick and precise small part production. The intuitive operation of the controls simplifies usage and increases productivity considerably.

- CNC surface & profile grinding machine

- e.g. 3 axes simultaneously

- Column feed for cross movement

- Dialogue input system

SURFACE GRINDERS

LINEAR 350 B

-

Manual precision surface grinding machine

With a grinding length of 350 mm and a cross travel of 150 mm the Linear 350B is ideally suited for the toolroom. It features a high level of standard equipment to ensure easy handling and the manual control allows quick and precise small part production.

- Machine base made of cast iron

- Vibration -reducing construction

- Table slideway with linear rollers

Additional equipment- Electro-magnetic chuck

- Balancing unit with arbour

- Wheel flange

ACC 450 AV

-

Precision surface and profile grinding machine

To avoid effects of heat expansion and vibration, the hydraulic unit is isolated from the main unit. For the purpose of long lifetime and maintenance free operation, oil lubrication with automatic lubrication is applied to the guide and slide way. Combination of both scraped V-V slide way and low friction Turcite assure accurate grinding for life. All castings exhibit high static and dynamic stiffness and excellent damping qualities.

- Surface and profile grinding machine

- Available with open cover as shown or with closed cover (open top)

- Popular and well proven latest generation Okamoto PLC controller

Additional equipment- Dust Suction System

- Coolant System

- Grinding wheel balancer

- Magnetic chuck

- Overhead Dresser – Manual

- Digital Readout for Crossfeed

- Spare wheel adaptor

ACC GX

-

Precision surface grinding machine

With a grinding length of 500 – 1000 mm and a cross travel of 200 –

500 mm the Okamoto DX Series is ideally suited for the toolroom.

It features a high level of standard equipment to ensure easy handling,

quick and precise small part production. The robust cast iron

construction and double-V slideways in both table and crossfeed

ensure long term precision.- Hydraulic surface grinder with automatic feed

- Moving saddle design

- Double-V slideways longitudinal and cross

- PLC controller with proven reliability

Additional equipment- Electro-permanent magnetic chuck

- Wheel head mounted Hydraulic dresser

- Paper band filter with coolant system

- Cross-feed digital readout

- Spindle speed inverter

ACC SA1 SERIES

-

Precision surface grinding machine

Next Generation Standard surface grinder series equipped with a newly developed user friendly controller.

- New control with LCD touch screen allows for easy monitoring of the machine functions and grind process

- Hydraulic table surface grinder with fully automatic grinding and dressing cycles

- Crossfeed setting by Teach-In

- Compact footprint design

- Auto dress with compensation is standard

- Spindle inverter unit is standard Auto-retract function is standard

Additional equipment

- Elektro-permanent magnetic chuck with chuck controller

- Paper band filter coolant system

- Temperature stabilized wheelhead

- Wheel balancing systems

- Wheel flange

ACC CA SERIES

-

Precision surface and profile grinding machine

With a grinding length of 600 – 1000 mm and a cross travel of 400 – 600 mm the Okamoto ACC-CA Series is ideally suited for the toolroom. It features a high level of standard equipment to ensure easy handling, quick and precise small part production. The robust cast iron construction and double-V slideways in the table ensure long term precision. The intuitive operation of the controls simplifies usage and increases productivity considerably.

Surface and profile grinding machine

Easy-to-use touch panel PLC controller

Moving column design

Magnetic chuck sizes from 600 x 400 to 1000 x 600 mmAdditional equipment

- Elektro-permanent magnetic chuck with chuck controller

- Paper band filter coolant system

- Temperature stabilized wheelhead

- Wheel balancing systems

- Wheel flange

DOUBLE COLUMN GRINDING

ACC CHIQ SERIES

-

Precision double column machine

The ACC-CHiQ series meets the very highest requirements in terms of precision to be found in the manufacture for parts in tool and mould construction, in hot runner technology and punching die construction.

The cross slideways can be adjusted mechanically and can be realigned at any time as needed. In doing so, the CNC does not need to be compensated which in turn affords advantages in a higher surface quality and smoothness.- Double column machine

- Fanuc touchscreen control

- Simple data input via symbols

- Stable construction for the very highest geometry requirements

- Mechanically adjustable cross slideways

- Electro-permanent magnetic chuck

- Paper band filter coolant system

- Overhead dresser with compensation

- Column increase 200mm

PSG CHNC

-

Double column surface and profile grinding machine

With a grinding length of 2000 – 4000 mm and a cross travel of 1050 – 2050 mm the Okamoto ACC-CHNC Series is ideally suited for both toolroom and production use. It features a high level of standard equipment to ensure easy handling, quick and precise part production. The robust cast iron construction and double-V table slideways together with gantry cross slide ensure long term precision. The intuitive operation of the controls simplifies usage and increases productivity considerably.

- Double column machine

- Robust construction for the very highest geometry requirements

- Precision surface processing

- Conversation software

- Electro-permanent magnetic chuck

- Paper band filter coolant system

- Overhead dresser with compensation

- Column increase 200mm

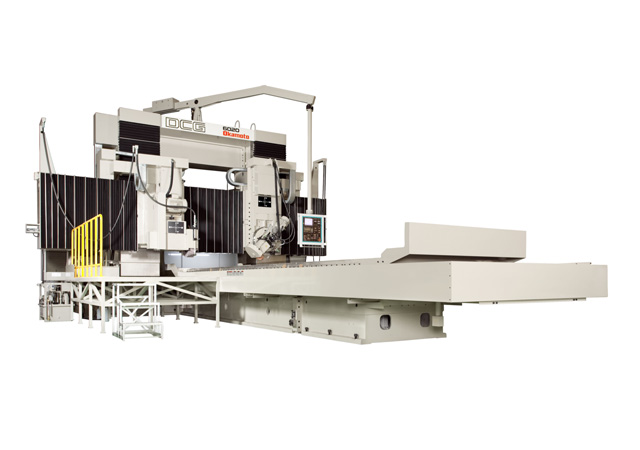

DCG NC TRAVELLING CROSSRAIL TYPE

-

Double column surface and profile grinding machine

With a grinding length of 2m – 4m and a cross travel of 1.5m – 2m the Okamoto DCG-NC Series is ideally suited for both toolroom and production use. It features a high level of standard equipment to ensure easy handling, quick and precise part production. The robust cast iron construction and double-V table slideways together with gantry cross slide ensure long term precision. The intuitive operation of the controls simplifies usage and increases productivity considerably.

- Double column machine

- Max. grinding height 1.5m, 1.6m, and 1.8m depending on model size

- Robust construction for the very highest geometry requirements

- Precision surface processing

- Conversation software

UPG-NC ULTRA PRECISION – FIXED CROSSRAIL

-

Double column surface and profile grinding machine with hydrostatic slideways

With a grinding length of 2m – 4m and a cross travel of 1.5 – 2 m the Okamoto UPG-NC Series is ideally suited for both toolroom and production use. It features a high level of standard equipment to ensure easy handling, quick and precise part production. The robust cast iron construction and hydrostatic slideways together with gantry cross slide ensure long term precision. The intuitive operation of the controls simplifies usage and increases productivity considerably.

- Double column machine

- Robust construction for the very highest geometry requirements

- Precision surface processing

- Conversation software

UDG NC ULTRA PRECISION TRAVELLING CROSSRAIL TYPE

-

Double column surface and profile grinding machine with hydrostatic slideways

With a grinding length of 2m to 10m long and a cross travel of 1m to 3.5m the Okamoto UDG-NC Series is ideally suited for both toolroom and production use. The robust cast iron construction and hydrostatic slideways together with a moving cross rail ensure long term precision. The intuitive operation of the controls simplifies usage and increases productivity considerably.

- Double column machine

- Moving cross rail to allow work height 1.5m

- hydrostatic slideways

- Robust construction for the very highest geometry requirements

- Precision surface processing

- Conversation software

ROTARY TABLE GRINDING

PRG DXNC

-

Precision rotary table grinding machine

Horizontal spindle CNC rotary table grinding machine. This machine has a portal design, with moving column crossfeed. The table is in constant rotary motion, which adapts automatically to the changing grinding diameter. Furthermore, the table can be pivoted ± 1° for calibration.

- Rotary table grinding machine with horizontal spindle

- Variable table speed with constant cutting speed

- Portal design with cast iron construction

- FANUC control

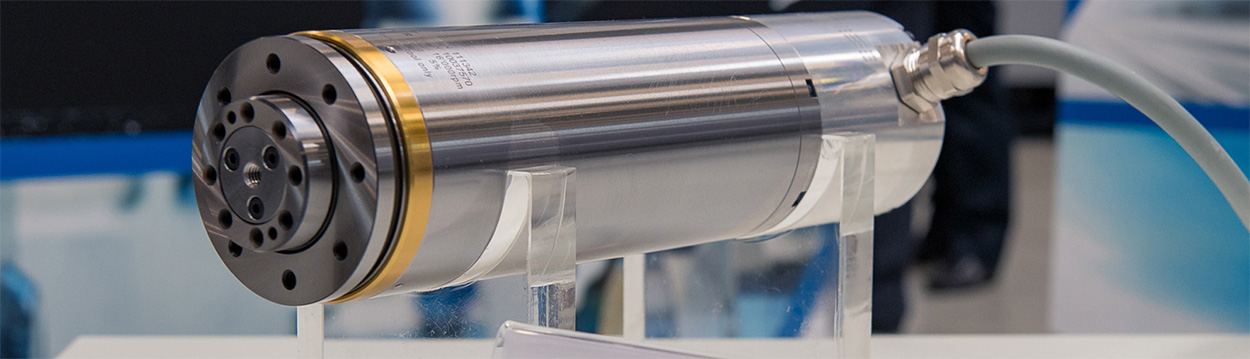

UPR-3NC

-

Ultra Precision Rotary Table Grinding Machine

Horizontal spindle CNC rotary table grinding machine. This machine has a column moving design with air bearing rotary table for the highest precision and best surface finish quality. The table is in constant rotary motion, which adapts automatically to the changing grinding diameter.

- 300mm diameter rotary table with horizontal spindle

- Variable table speed with constant cutting speed

- Column moving design with cast iron construction

- Air bearing precision table

- Liquid cooled ultra low vibration spindle motor

- FANUC control

PRG-10DXNC – PRG-12DXNC

-

Large Size Precision Rotary Table Grinding Machine with hydrostatic table

Horizontal spindle CNC rotary table grinding machine. This machine has a column moving design with hydrostatic rotary table for extra weight carrying capacity. The table is in constant rotary motion, which adapts automatically to the changing grinding diameter.

- Rotary table grinding machine with horizontal spindle

- Variable table speed with constant cutting speed

- Column moving design with cast iron construction

- FANUC control

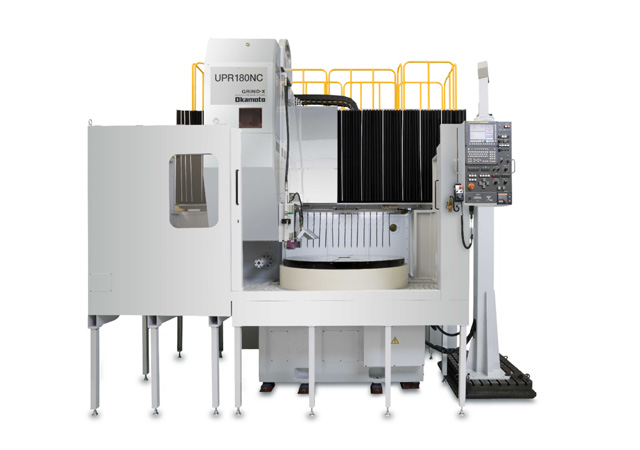

UPR-180NC

-

Extra Large Size Precision Rotary Table Grinding Machine with hydrostatic table

Horizontal spindle CNC rotary table grinding machine. This machine has a double column construction with hydrostatic rotary table for extra weight carrying capacity. The table is in constant rotary motion, which adapts automatically to the changing grinding diameter.

- 1.8m diameter table.

- Rotary table grinding machine with horizontal spindle

- Variable table speed with constant cutting speed

- Heavy duty double column construction

- FANUC control

POLISHING MACHINES

AERO LAP

-

Finishing system for polishing / lapping irregular profiles

For extremely fine lapping of irregular profiles, AERO LAP is also equipped for small tools and parts. The special suspension multicone enables an automated lapping process without changing the geometry of the components to be worked. Multicone is a special elastic carrier medium to which diamond powder has been added. The media is directed onto the workpiece via a nozzle from a special turbine.

- Easy lapping of irregular profiles

- Improves tool life of all tools (drills, milling cutters, form punches, etc.)

- Suitable for PVD/CVD coating (pre/mirror-gloss lapping)

- Negligible production of dust and odour

CYLINDRICAL GRINDING

OGM Series Cylindrical Grinding Machines

OGM 250 UDXB

-

Universal cylindrical grinding machine

A Universal cylindrical grinding machine having a diameter capacity of 200 mm and with 500 mm between centres, the OGM 250 UDXB is ideally suited for toolroom small batch production. It is delivered with a comprehensive level of standard equipment to suit toolroom production and allows quick and easy setup. The stable design of the spindle head together with double-V table slideways provides for a robust machine with long-term precision. The intuitive operation of the controls simplifies usage and increases productivity considerably.

- Proven PLC type Okamoto DX control

- With internal grinding unit in the standard equipment

- AC motor ball screw table drive mounted on a T-shaped cast iron machine bed

OGM EXIII SERIES

-

Precision cylindrical grinding machine

Equipped with a Fanuc touch screen control, the OGM-EXIII Series has been optimised for quick and easy setups for single diameter grinding in a toolroom environment. Additional options include software with 10-step grinding program and a Z axis offset touch probe. Entry of grinding data is quick and easy via the colour touchscreen.

- External only version with large diameter 450mm wheel

- Universal version with manual swivel +/-30 deg.

- Universal version with optional swing down internal grinding unit

- FANUC touchscreen control featuring easy to use software

- Sizes from 500 mm to 1500 mm between centres

OGM NCIII SERIES

-

Precision cylindrical grinding machine

The OGM-NCIII Series includes a wide variety of standard equipment including Z axis shoulder locator and gap eliminator. The standard software with 10-step grinding program allows quick and easy data entry via the Fanuc colour touchscreen. Further software options such as profile grinding are also available. Wheel and work spindles are driven by Fanuc AC servomotors.

- External only version with large diameter 450mm wheel

- Universal version with manual swivel +/-30 deg.

- Universal version with optional swing down internal grinding unit

- FANUC touchscreen control featuring easy to use software

- Sizes from 500 mm to 1500 mm between centres

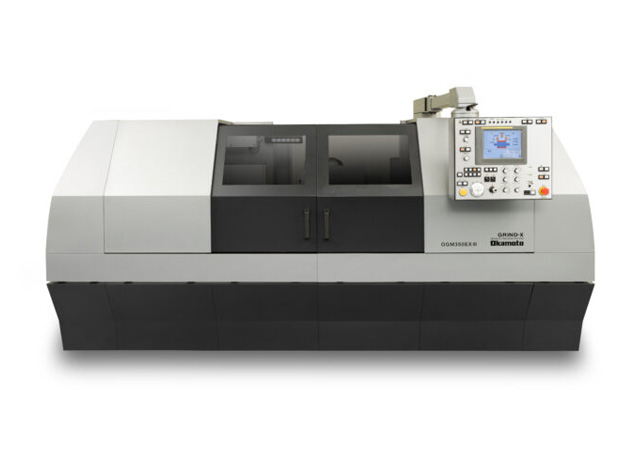

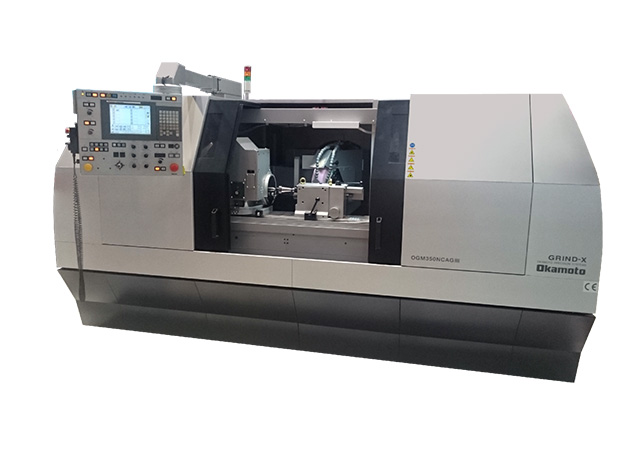

OGM-350NCAGIII

-

Precision cylindrical grinding machine

The OGM-350NCAGIII angle head cylindrical grinder includes a wide variety of standard equipment including Z axis shoulder locator and gap eliminator. The standard software with 10-step grinding program allows quick and easy data entry via the Fanuc colour touchscreen. Further software options such as profile grinding are also available. Wheel and work spindles are driven by Fanuc AC servomotors.

- Large diameter 510mm wheel set at a fixed angled of 30 degrees

- Powerful high torque Fanuc wheel spindle motor

- FANUC touchscreen control featuring easy to use software

Internal & Universal Cylindrical Grinders with automatic B axiss

IGM 15 NCIII

-

Internal grinding machine with single spindles

Standard software with 10-step grinding program Software for plain bore, taper and contour grinding with 2-axis control. Entry of grinding data via touchscreen with easy to use software. Wheel and workhead spindles are driven by AC servomotors.

- Internal cylindrical grinding machine with standard spindle speed 20,000rpm

- Optional spindle speeds from 10,000 to 60,0000rpm

- FANUC touchscreen with easy to use software input

IGM 15 NCIII-2

-

Internal grinding machine with single spindles

Standard software with 10-step grinding program Software for plain bore, taper and contour grinding with 2-axis control. Entry of grinding data via touchscreen with easy to use software. Wheel and workhead spindles are driven by AC servomotors.

High precision is further optimized via thermally stabilized infeed ball screw.- Twin spindle with standard spindle speed 10,000rpm and 30,000rpm

- Optional spindle speeds available up to 60,0000rpm

- Highly accurate oil cooled in-feed ball screw

- FANUC touchscreen with easy to use software input

UGM 5V

-

Precision vertical universal cylindrical grinding machine with B axis

With the introduction of this new universal series of vertical and internal grinding machines, Okamoto combines its extensive know-how in the field of internal and external grinding in an entirely new design.

- CNC universal vertical grinding machine

- Pivoting wheel head (B axis)

- Automatic Tool Changer for 4 wheels

- Roundness 0.9 μm

UGM NC SERIES

-

Precision universal cylindrical grinding machine with B-axis

Standard software with 10-step grinding program. Software for profile grinding optionally available. Entry of grinding data via touchscreen. Wheel and work spindles driven by Fanuc AC servomotors. A swing down wheel dressing device for internal grinding is included in the standard equipment.

- Double V table slideways

- T-shaped machine bed

- Temperature-stabilized spindles

- Low-maintenance B-axis motor with direct drive

- Directly powered ball screws