- Offer Profile

- sssss

HIGHLY PRECISE EROSION AND TOOL GRINDING MACHINES

-

SOLUTIONS FOR ROTARY TOOLS

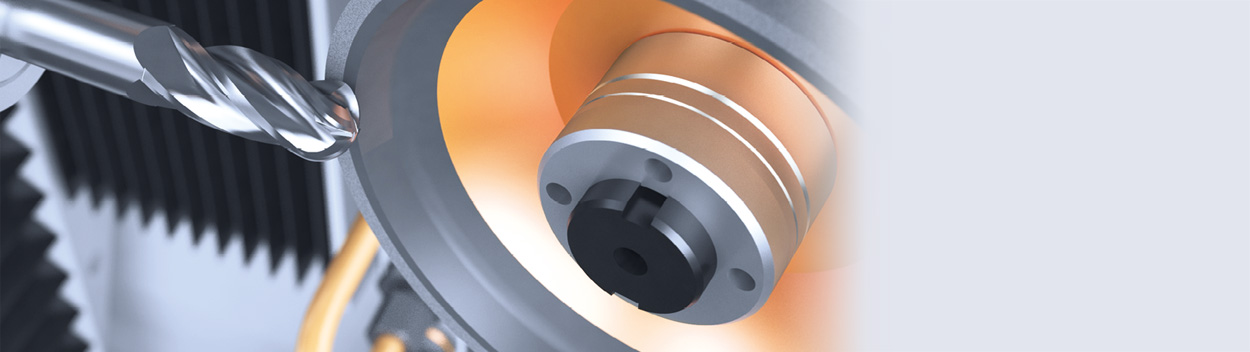

Metals and lightweight materials are essential in many industry sectors, such as the car manufacturing and aerospace industries. These materials, as well as highly abrasive laminates and other materials in the woodworking industry, can only be machined economically by particularly high-performance, high precision tools. The rotary tools used for this type of machining are manufactured from carbide or PCD blanks, or are equipped with PCD cutting edges. Vollmer offers sharpening machines that are controlled accordingly by CNC technology for both tool types.

The sharpening process plays a key role in the production of drills, milling cutters and chippers made of PCD or carbide. The sharpening process determines the tool's level of precision and service life, as well as being the definitive mark of quality. It also sets the highest standards for the tool grinding machines used for their manufacture or machining.

VOLLMER erosion and grinding machines meet these high quality standards.

POWERFUL EROSION MACHINES FOR PCD TOOL MACHINING

-

Efficient, high-precision machining is the key to the manufacture of PCD rotary tools.

VOLLMER has a unique portfolio of intelligent, powerful high-tech CNC-controlled erosion machines specifically for machining complex rotary tools – both for production and service.BENEFITS OF VOLLMER EROSION MACHINES FOR PCD

With VOLLMER, you have a strong and forward-thinking partner by your side. We will help you establish an effective presence when facing the global competition.

As a result, you will benefit from:

- High reliability

- Precise results

- Greater operating comfort

- Maximum productivity in manufacture of rotary tools

- Tailored Services

For machining PCD tools, Vollmer's portfolio includes wire and disc erosion machines, which are lightweight and easy to operate. With the unique operating concept, you can carry out complex sharpening or grinding tasks quickly, safely and reliably after just a short period of training. Moreover, thanks to the high accuracy and surface quality achieved by every VOLLMER machine, grinding can even be omitted in many cases.

Whether the automotive, aviation or aerospace industry, whether machining aluminum, magnesium, MMX or highly abrasive laminates: VOLLMER offers the technologies you need for manufacturing and processing the respective rotary tools. Of Course, the same applies for complete machining including measuring, eroding, grinding and polishing. Special machine configurations with integrated infeed device and workpiece magazines enable fully automated sharpening around the clock, on a multi-shift basis and on weekends. With "ExLevel", we provide you with an intelligent software solution, which creates the most realistic simulation of your tool production.

QXD 250 - MORE FLEXIBILITY IN PRECISION

-

Disc erosion machine with six CNC-controlled axes for the complete machining of PCD-tipped precision tools. NEW: With powerful VPulse EDM erosion technology.

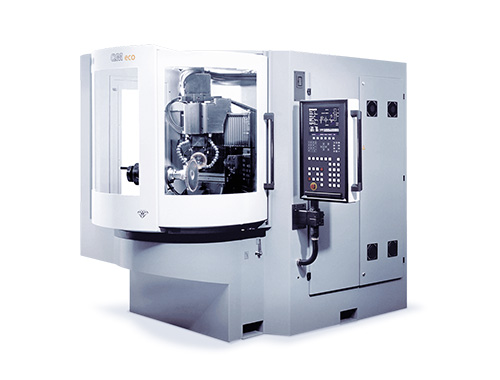

QM ECO SELECT - DISC EROSION MACHINE FOR MACHINING PCD TOOLS

-

Disc erosion machine with five CNC-controlled axes and two manual axes. Automatically erode and measure tools with unsupported clamping. For cutting edges made of PCD and other hard materials.

VPULSE 500 - HIGHLY-EFFICIENT WIRE EROSION MACHINE FOR THE MANUFACTURE AND SERVICE OF PCD-TIPPED TOOLS

-

Wire erosion machine with customized five-axis kinematics for machining PCD-tipped rotary tools. Powerful control in combination with the new VPulse EDM erosion generator. Innovative operating concept, reliable software, highly developed human-machine interaction.

CARBIDE TOOL GRINDING MACHINES FOR ULTRA-PRECISE ROTARY TOOLS

-

When brittle, hard metal materials coalesce with relatively soft metals, primarily from the iron family (iron, cobalt, nickel); a material is created that is characterized by a high level of hardness as well as viscosity, known as carbide.

Its huge resistance to wear and capacity to withstand even massive physical loads make it a much sought-after material in many sectors: Including mechanical engineering, the automotive, steel or food industry.Machining processes such as rotating, milling, drilling, engraving, sharpening and grinding are almost inconceivable without carbide. It is also used in non-cutting forming or for protection against wear. In the field of tool manufacturing, the hard metal is mainly used for indexable inserts, as solid carbide rods or in the form of precision tools like drills and milling cutters.

BENEFITS OF CARBIDE GRINDING WITH VOLLMER

- More precision – be impressed by the uncompromising accuracy

- More efficiency – experience productivity on a new level

- More user comfort – simplify your work

- More flexibility – for precision in any format desired

EFFICIENCY SQUARED: VOLLMER VGRIND 360 - CARBIDE TOOLS SMARTER PRODUCTION

-

Tool grinding machine for the production of carbide drills and milling cutters with a diameter of up to 100 mm. The workpieces can be machined on two vertically configured grinding spindles. The optional tool automation for eight tools changes the grinding wheels on both grinding spindles in the shortest time possible.

VGRIND 360E - COST EFFICIENCY SQUARED

-

Grinding machine for the cost-effective complete machining of carbide tools up to 100 mm in diameter

CIRCULAR SAW SHARPENING MACHINERY FOR BEST SAW PRODUCTIVITY

-

MORE PRODUCTIVE CUTTING

Professional care and maintenance is the key to effective and productive use of your carbide or high-speed steel circular saw blades.

VOLLMER has a uniquely diverse portfolio of high-performance advanced grinding machines for sharpening, maintaining or brazing circular saws. For tool production, chipping saw mills or a sharpening service – VOLLMER has the right solution for your specific needs. And there's more to the blades than just grinding them; we also have impressive solutions for other important process steps for your circular saw.

BENEFITS OF VOLLMER SHARPENING MACHINES FOR CIRCULAR SAW BLADES

VOLLMER technologies, ranging from manual sharpening machines to handling systems for fully automated complete machining, ensure that circular saw blades are ground to your requirements. The variety of solutions matches the economic efficiency and quality of your machining process while guaranteeing maximum precision. The VOLLMER sharpening machines for circular saw blades considerably improve your production processes in circular saw machining. With VOLLMER technologies and services, you benefit form:- High cutting output

- Improved cutting quality

- Longer operating life

- Increased productivity

- Greater operating comfort

MACHINING THE SIDE ANGLE

-

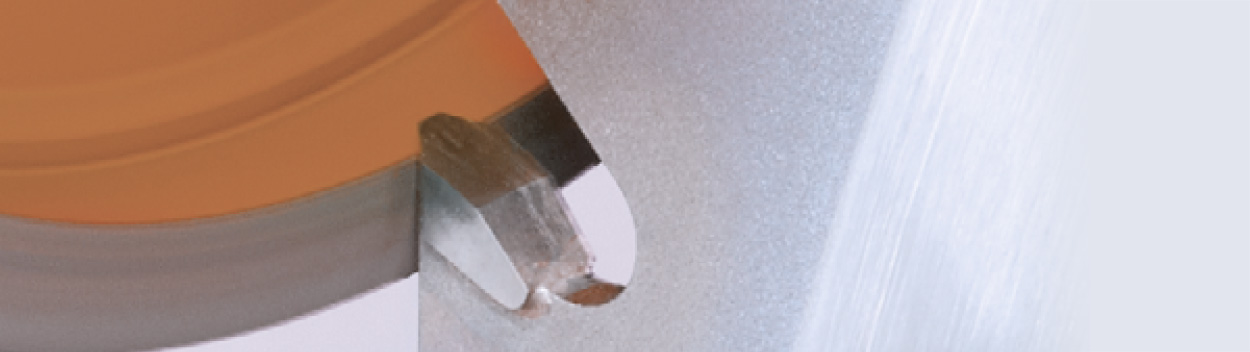

PERFECTION IN GRINDING SIDE ANGLES OF CIRCULAR SAWS

When it comes to grinding circular saws, a precisely ground tooth side contributes significantly to the surface quality and cutting quality. For sharpening, maintenance or annealing, VOLLMER has the ideal solution tailored to your needs in the treatment process.

SIDE GRINDING MACHINES FOR MAXIMUM PRECISION

In addition to best cutting results, VOLLMER machines offer you a multitude of advantages when machining the side angles of your circular saw blades:- Compact design

- Sturdy machine structure

- Ease of maintenance

- Accurate sharpening results

- Easy to use

- Outstanding surface quality of the workpieces

- Flexibility with regard to diameter and tooth shape

CPF 650

-

Grinding machine with five CNC-controlled axes for peripheral grinding on both sides. For automatic machining of carbide-tipped circular saw blades with different diameters and tooth shapes on the side angle.

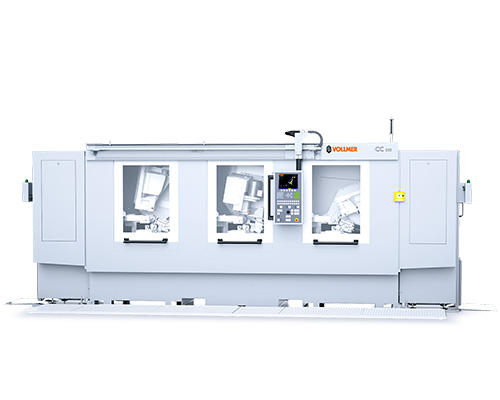

CC 355

-

Production system for sharpening tooth faces, tooth tops and side angles. Three machining stations, 17 CNC axes, machining of up to 800 teeth per hour.

QF 270

-

Disk erosion machine with eight CNC-controlled axes. For automatic measurement and erosion of PCD circular saw blades on the sides. Can be connected to an ND robot system.

CMF 300

-

Machine for machining the side angle on carbide-tipped circular saws with a circular saw blade external diameter of 200 to 1440 mm.

CMF 200

-

Machine for machining the side angle on carbide-tipped circular saw blades.

CHF 270

-

Grinding machine with seven CNC-controlled axes for peripheral grinding on both sides. For automatic machining of carbide-tipped circular saws with different diameters and tooth geometries on the sides.

CHF 1300

-

CNC-controlled machine for sharpening tooth sides on carbide-tipped circular saws up to 1300 mm in diameter.

CHF 840

-

Side machining of saws for the saw mill industry, woodworking, plastics processing, aluminum processing and metalworking.

CHHF 21H

-

Grinding machine for flank grinding on one side of the saw blade. For manual machining of carbide-tipped circular saws with different diameters.

MACHINING TOOTH FACES AND TOOTH TOPS

-

TOOTH TOP AND TOOTH FACE GRINDING FOR BEST CIRCULAR SAW PERFORMANCE

Professional treatment and care of your circular saws is the key to efficiency and productivity. For tooth tops or faces of saw blades – we have the perfect solution for every task.

Grinding tooth faces and tops is essential for the productivity of a carbide saw blade. With intelligent machine concepts, maximum precision and convenient operation, VOLLMER offers you the ideal solution for excellent surface quality. The saw face grinding machines are characterized by their sturdy structure and a high level of robustness and durability.

THE MAIN ADVANTAGES AT A GLANCE

The accurate sharpening results achieved by VOLLMER machines when grinding tooth tops and tooth faces of circular saws is the result of a whole host of advantages:

- Compact design

- Sturdy machine structure

- Ease of maintenance

- Easy to use

- Outstanding grinding finish

- Shorter service visits

- Optimally adjusted to applications and requirements

CHX 1300

- Versatile sharpening machine for TCT circular saw blades up to 1300 mm in diameter

CHX 840

- Versatile sharpening machine for TCT circular saw blades up to 840 mm in diameter

QR 270

- Disk erosion machine with eight CNC-controlled axes. For automatic measurement and erosion of PCD circular saw blades on the tooth top. Can be connected to an ND robot system.

CC 355

- Production system for sharpening tooth faces, tooth tops and side angles. Three machining stations, 17 CNC axes, machining of up to 800 teeth per hour.

CM 300

- Sharpening machine for machining of tooth faces and tooth tops on carbide-tipped circular saw blades.

CM 200

- Sharpening machine with eight CNC-controlled axes and measuring equipment. For automatic machining of carbide-tipped circular saw blades with different diameters and tooth geometries on the face and top. Option: Preparation for connection to an ND robot system.

CHD 270

- Sharpening machine with eight CNC-controlled axes and measuring equipment. For automatic machining of carbide-tipped circular saw blades with different diameters and tooth geometries on the face and top. Option: Preparation for connection to an ND robot system.

CHP 1300

- Universal sharpening machine for carbide-tipped circular saw blades up to 1300 mm in diameter. For workshop-oriented grinding of saw blades in wood, aluminum and plastics processing, and also in metal processing.

CHP 840

- Universal sharpening machine for carbide-tipped circular saw blades up to 840 mm in diameter. For workshop-oriented grinding of saw blades in wood, aluminum and plastics processing, and also in metal processing.

CHC 1300

- Flexible sharpening machine for carbide-tipped circular saw blades up to 1300 mm in diameter. For workshop-oriented treatment of saw blades in aluminum, plastics and particularly in wood processing.

CHC 840

- Flexible sharpening machine for carbide-tipped circular saw blades up to 840 mm in diameter. For workshop-oriented grinding of saw blades in aluminum, plastics and, in particular, wood processing.

CP 650

- Four CNC-controlled axes for automatic machining of carbide-tipped circular saw blades with different diameters and tooth geometries on the face and top.

METAL PROCESSING BANDSAWS

-

Carbide-tipped band saw blades are finding more and more applications in the metal-cutting industry. They are mainly distinguished by their small dimensions in relation to the often oversized pieces that need to be cut down. The advantage of carbide-tipped bandsaw blades for cutting metal lies in the very narrow cutting channel and the small machining losses.

In carbide-tipped bandsaws, small carbide pieces are welded onto a special carrier material that is highly resistant to various forces and stresses, even at high cutting speeds. Through fine grinding, the teeth obtain their vertical geometries, which depends on the material to be cut. The effective use of bandsaws for cutting metal requires maximum precision in the tooth geometry. That's a fact – and we know it. That's why, at VOLLMER, we have tried-and-tested solutions that have been specially developed and constructed for these requirements: For grinding tooth tops, straight tooth faces and clearance surfaces on both sides.

And in the last 100 years, we have not just focused on machines, but also on the people who operate them. In order to make work as easy, safe and pleasant as possible, we abide by the VOLLMER operating concept: Intuitive and logical.

THE MOST IMPORTANT ADVANTAGES OF OUR SAW BLADE GRINDING MACHINES:

- Compact design

- Sturdy machine structure for precise sharpening results

- Easy to maintain due to the separation of the machine compartment and operating area

- Simple operation

- Outstanding grinding finish

- High output and economic efficiency

- Shorter service visits

- Advanced technology

- Optimally adjusted to applications and requirements

CB 200

- Sharpening machine for carbide-tipped band saw blades.

CB 400

- Automated sharpening machines for carbide-tipped band saw blades.

CBF 400

- Automated sharpening machines for carbide-tipped band saw blades.