- Offer Profile

- KELLER Pressure headquartered in Winterthur (Switzerland), is Europe’s leading manufacturer of isolated pressure transducers and transmitters. The company, which has a global workforce of around 450 employees, was founded in 1974 by Hannes W. Keller, a graduate in physics and the inventor of the integrated silicon measuring cell. The entire value creation, from production of the individual parts and calibration of the sensor through to the final inspection of the finished products, takes place at the headquarters in Winterthur. All KELLER Pressure products are therefore “Made in Switzerland”.

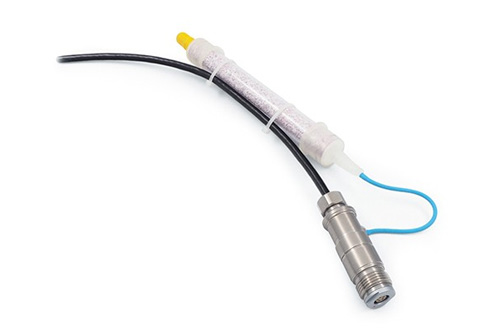

Pressure Transducers

- Encapsulated piezoresistive pressure transducers for absolute and gauge pressure measurement are KELLER Pressure's core competence and lie at the heart of all KELLER Pressure products for end users. They have proved their worth millions of times over and are a reliable base for any measuring system. Transducers can be adjusted and optimised according to your needs.

OEM Pressure Transducers

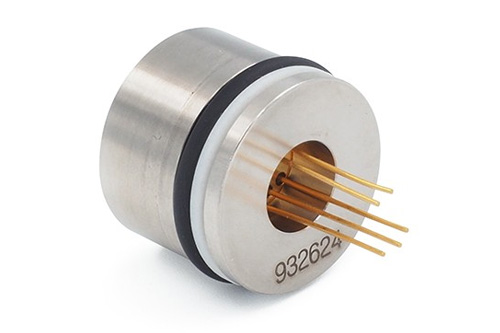

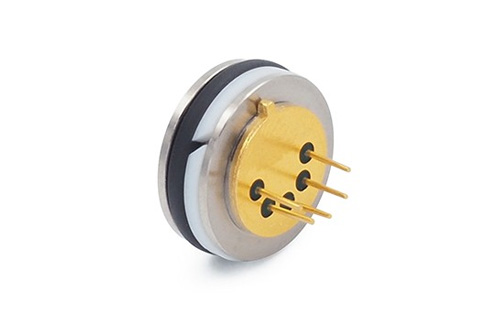

Series 10L

-

The pressure transducers of the 10L series have a robust housing made of stainless steel, giving them optimum long-term stability for a range of OEM applications. The metal diaphragm is welded on front-flush and gap-free, separating off the piezoresistive pressure sensor, which is made of silicon, from the measuring medium. Every pressure transducer is measured over the entire pressure and temperature profile and is supplied with a detailed calibration sheet.

Specifications

- Pressure Ranges: 0...0,1 to 0...200 bar

- Accuracy: ±0,25 %FS

- Long Term Stability: ±0,15 %FS

- Dimensions: ø 19 mm x 15 mm

- Temperature Range: -40...125 °C

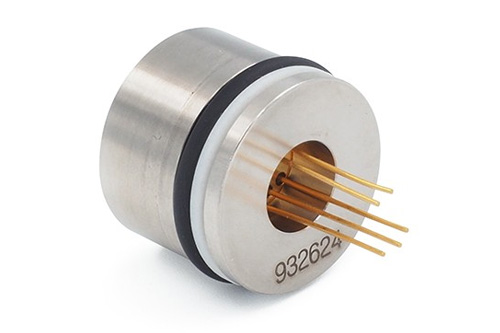

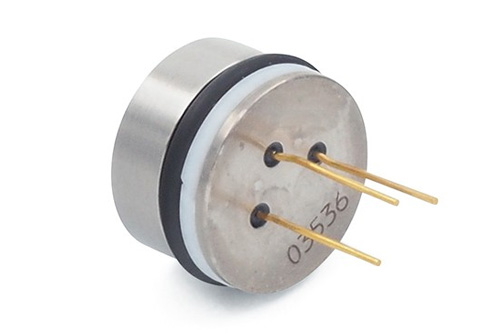

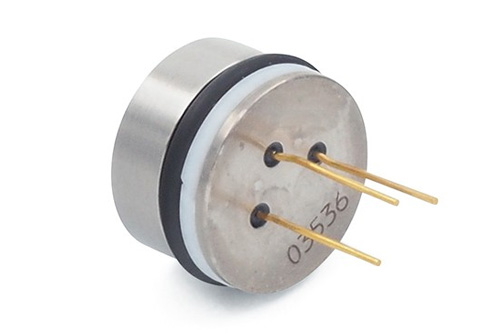

Series 9L

-

The pressure transducers of the 9L series have a compact, robust housing made of stainless steel, giving them outstanding long-term stability for a range of OEM applications. The metal diaphragm is welded on front-flush and gap-free, separating off the piezoresistive pressure sensor, which is made of silicon, from the measuring medium. Every pressure transducer is measured over the entire pressure and temperature profile and is supplied with a detailed calibration sheet.

Specifications

- Pressure Ranges: 0...0,2 to 0...200 bar

- Accuracy: ±0,25 %FS

- Long Term Stability: ±0,2 %FS

- Dimensions: ø 19 mm x 5 mm

- Temperature Range: -40...125 °C

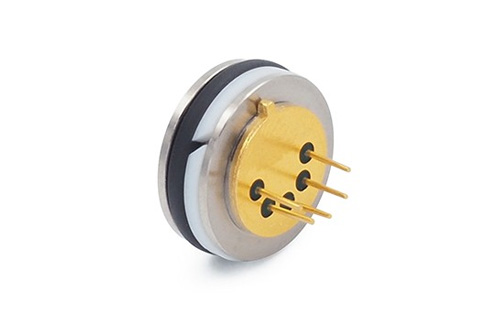

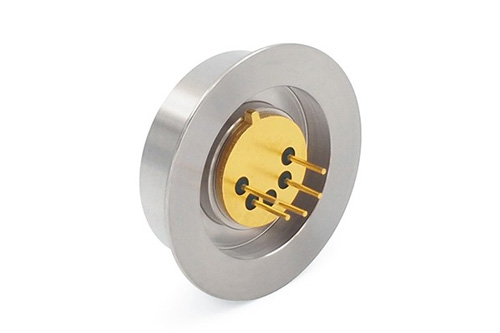

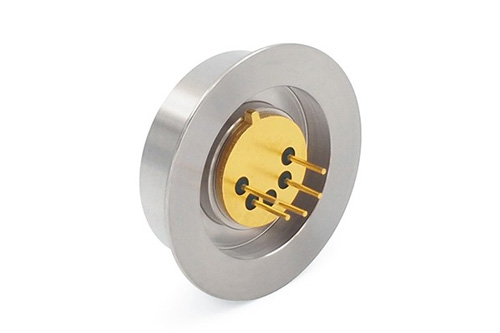

Series 9FL

-

The pressure transducers of the 9FL series have a compact, robust housing made of stainless steel, giving them outstanding long-term stability for a range of OEM applications. The metal diaphragm is welded on front-flush and gap-free, separating off the piezoresistive pressure sensor, which is made of silicon, from the measuring medium. The additional flange on the housing means that it can be welded to another housing, or an axial seal can be used. Every pressure transducer is measured over the entire pressure and temperature profile and is supplied with a detailed calibration sheet.

Specifications

- Pressure Ranges: 0...0,2 to 0...200 bar

- Accuracy: ±0,25 %FS

- Long Term Stability: ±0,2 %FS

- Dimensions: ø 17 mm x 5,5 mm

- Temperature Range: -40...125 °C

Series 7L

-

The pressure transducers of the 7L series have a compact, robust housing made of stainless steel, giving them excellent long-term stability for a range of OEM applications. The metal diaphragm is welded on front-flush and gap-free, separating off the piezoresistive pressure sensor, which is made of silicon, from the measuring medium. Every pressure transducer is measured over the entire pressure and temperature profile and is supplied with a detailed calibration sheet.

Specifications

- Pressure Ranges: 0...5 to 0...200 bar

- Accuracy: ±0,5 %FS

- Long Term Stability: ±0,25 %FS

- Dimensions: ø 15 mm x 5 mm

- Temperature Range: -20...100 °C

Series 4L

-

Series 3 L…10 L are a new generation of transducers from KELLER which feature smaller capsule dimensions and a crevice-free diaphragms. KELLER’s expertise in laser welding very thin materials enables the production of a line of transducers with a crevice-free media interface while improving on performance and long-term stability.

Each transducer undergoes extensive automated testing and is supplied with calibration data which includes sensitivity, linearity, initial zero offset and thermal effects over the compensated temperature range. This provides the user with the information required to ensure performance within specifications.

Specifications

- Pressure Ranges: 0…10 to 0…200 bar

- Accuracy: ±0,5 %FS

- Long Term Stability: ±0,5 %FS

- Dimensions: ø 11 mm x 4,2 mm

- Temperature Range: -10...80 °C

OEM High-Pressure Transducers

Series 7LHP

-

The high-pressure transducers of the 7LHP series have a robust housing made of stainless steel, giving them optimum long-term stability for a range of OEM applications. The metal diaphragm is welded on front-flush and gap-free, separating off the piezoresistive pressure sensor, which is made of silicon, from the measuring medium. Every pressure transducer is measured over the entire pressure and temperature profile and is supplied with a detailed calibration sheet.

Specifications

- Pressure Ranges: 0…100 to 0…2000 bar

- Accuracy: ±0,5 %FS

- Long Term Stability: ±0,25 %FS

- Dimensions: ø 15 mm x 8 mm

- Temperature Range: -55…180 °C

- Material: Steel 1.4435, Inconel 718, Titanium

Series 6LHP

-

The high-pressure transducers of the 6LHP series have a robust housing made of stainless steel, giving them optimum long-term stability for a range of OEM applications. The metal diaphragm is welded on front-flush and gap-free, separating off the piezoresistive pressure sensor, which is made of silicon, from the measuring medium. Every pressure transducer is measured over the entire pressure and temperature profile and is supplied with a detailed calibration sheet.

Specifications

- Pressure Ranges:0…100 to 0…2000 bar

- Accuracy: ±0,5 %FS

- Long Term Stability: ±0,25 %FS

- Dimensions: ø 13 mm x 8 mm

- Temperature Range: -40…150 °C

- Material: Steel 1.4435, Hastelloy C-276, Inconel 718

Series 10LHP

-

The high-pressure transducers of the 10LHP series have a robust housing made of stainless steel, giving them optimum long-term stability for a range of OEM applications. The metal diaphragm is welded on front-flush and gap-free, separating off the piezoresistive pressure sensor, which is made of silicon, from the measuring medium. Every pressure transducer is measured over the entire pressure and temperature profile and is supplied with a detailed calibration sheet.

Specifications

- Pressure Ranges: 0...200 to 0...1000 bar

- Accuracy: ±0,25 %FS

- Material: Steel 1.4435

- Dimensions: ø 19 mm x 15 mm

- Temperature Range: -20...100 °C

OEM Differential Pressure Transducers

Series PD-10L

-

The pressure transducers of the PD-10L series have been developed to measure differential pressure. These OEM pressure transducers have a single silicon diaphragm in their interior, which is pressurised from both sides and measures the pressure difference directly. This design enables them to measure tiny pressure differences even at an extremely high line pressure.

Specifications

- Pressure Ranges : 0…0,1 to 0…30 bar

- Line Pressure: 200 bar

- Accuracy: ±0,25 %FS

- Long Term Stability: ±0,15 %FS

- Dimensions: ø 19 mm x 26 mm

- Temperature Range: -40...125 °C

Series PD-10LHP

-

The pressure transducers of the PD-10LHP series have been developed to measure differential pressure. These OEM pressure transducers have a single silicon diaphragm in their interior, which is pressurised from both sides and measures the pressure difference directly. This design enables them to measure tiny pressure differences even at an extremely high line pressure.

Specifications

- Pressure Ranges : 0…0,1 to 0…30 bar

- Line Pressure: 600 bar

- Accuracy: ±0,25 %FS

- Long Term Stability: ±0,15 %FS

- Dimensions: ø 19 mm x 26 mm

- Temperature Range: -40...125 °C

OEM Pressure Transducers with Thread

Series 20

-

The pressure transducers of the 20 series with threaded connection offer high long-term stability and overload resistance as well as optimised temperature behaviour. The compact, robust stainless steel housing without internal seals is suitable for various OEM applications. Each pressure transducer is calibrated via pressure and temperature and supplied with a detailed calibration sheet.

Specifications

- Pressure Ranges: 0…5 to 0…600 bar

- Accuracy: ±0,5 %FS

- Pressure Connection: G1/4, 1/4-18NPT

- Dimensions: HEX19 x 32mm

- Temperature Range:-10…80 °C

Series 6

-

The pressure transducers of the 20S series with threaded connection offer high long-term stability and overload resistance as well as optimised temperature behaviour. The compact stainless steel housing without internal seals is suitable for various OEM applications. Each pressure transducer is calibrated via pressure and temperature and supplied with a detailed calibration sheet.

Specifications

- Pressure Ranges: 0…0,3 to 0…1000 bar

- Accuracy: ±0,25 %FS

- Pressure Connection: G1/4, 1/4-18NPT

- Dimensions: HEX22 x 34mm

- Temperature Range: -10...80 °C

Series 13

-

The series 13 pressure transducers have internal water cooling and are suitable for use in media temperatures of up to 350 °C. Typical applications include superheated steam circuits, engine test benches or chemical process monitoring.

Specifications

- Pressure Ranges: 0…10 to 0…1000 bar

- Accuracy: ±0,5 %FS

- Pressure Connection: M14 x 1,2

- Dimensions: ø 28 mm x 48 mm

- Temperature Range: 20...350 °C

OEM Pressure Transducers Special Designs

Series 3L

-

The pressure transducers of the 3L series have a small and compact design, making them ideally suited to OEM applications with limited installation space. The metal diaphragm is welded on front-flush and gap-free, separating off the piezoresistive pressure sensor, which is made of silicon, from the measuring medium. Every pressure transducer is measured over the entire pressure and temperature profile and is supplied with a detailed calibration sheet.

Specifications

- Pressure Ranges : 0...20 to 0...200

- Accuracy: ±0,5 %FS

- Long Term Stability: ±0,5 %FS

- Dimensions: ø 9,5 mm x 4,2 mm

- Temperature Range: 20...30 °C

Series 6L

-

The pressure transducers of the 6L series have a small and compact design, making them ideally suited to OEM applications with limited installation space. The metal diaphragm is welded on front-flush and gap-free, separating off the piezoresistive pressure sensor, which is made of silicon, from the measuring medium. Every pressure transducer is measured over the entire pressure and temperature profile and is supplied with a detailed calibration sheet.

Specifications

- Pressure Ranges : 0...10 to 0...200

- Accuracy: ±0,5 %FS

- Long Term Stability: ±0,35 %FS

- Dimensions: ø 13 mm x 4,5 mm

- Temperature Range: -10...80 °C

Series 8L

-

The pressure transducers of the 8L series have a compact, robust housing made of stainless steel, giving them excellent long-term stability for a range of OEM applications. The metal diaphragm is welded on front-flush and gap-free, separating off the piezoresistive pressure sensor, which is made of silicon, from the measuring medium. Every pressure transducer is measured over the entire pressure and temperature profile and is supplied with a detailed calibration sheet.

Specifications

- Pressure Ranges : 0…0,2 to 0…200 bar

- Accuracy: ±0,5 %FS

- Long Term Stability: ±0,2 %FS

- Dimensions: ø 17 mm x 7 mm

- Temperature Range: -40...125 °C

Miniature Pressure Transducers without Oil Filling

Series M5

-

The miniature pressure transducer M5 takes its name from the fine M5 thread at the sensor head that makes it possible to take measurements in places which are difficult to access and in narrow pipelines. Together with its ability to measure media at temperatures of up to 180 °C in a dynamic range from 0 to 50 kHz, this makes it ideally suited to measurements on engine test benches.

Specifications

- Pressure Ranges : 0...3 to 0...30 bar

- Accuracy: ±0,3 %FS

- Pressure Connection: M5 x 0.5 thread

- Dimensions: ø 6,2 mm x 40 mm

- Temperature Range: -50...180 °C

Series 2Mi

-

These low-cost miniature pressure transducers have been specially developed for very rapid hydrodynamic and aerodynamic in situ pressure measurements. The 2Mi sensors are available in a variety of housing designs and can simply be stuck on at the desired location. Despite its miniature design, the sensor chip is protected against external influences by a steel housing and a silicone elastomer coating. It can also be used in liquids.

Specifications

- Pressure Ranges : 0…1 to 0…400 bar

- Accuracy: ±0,5 %FS

- Pressure Connection: Elastomer coating

- Dimensions: ø 4,5 mm x 3 mm

- Temperature Range: -20...80 °C

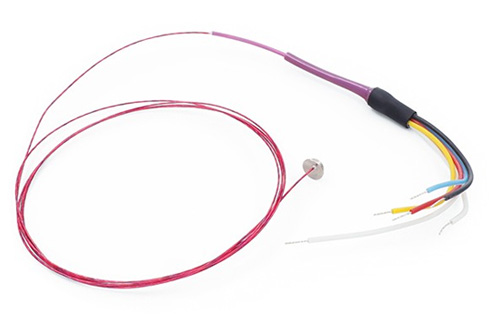

Catheters

-

These medical catheters for applications in urology, cardiology and gastroenterology are compatible with common monitor systems. A range of sizes (4F to 8F) and a modular design make it possible to construct all manner of sequences of measuring cells and lumen openings.

Specifications

- Pressure Ranges : -0,5…0,5 bar

- Accuracy: ±0,5 %FS

- Pressure Connection: 4F / 5F / 6F / 8F

- Dimensions: ø 1,33…2,67 mm

- Temperature Range: 20...40 °C

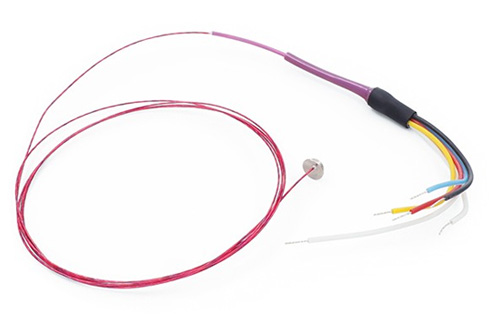

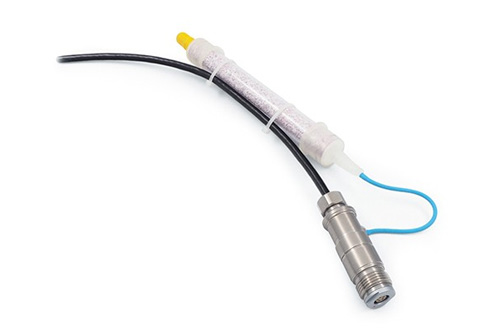

Tip sensors

-

These miniature pressure probes are designed for measuring the flow and dynamic pressure of liquids and gases in pipelines. With diameters between 1,32 mm and 2,64 mm and a flexible yet robust cable, these probes can also be used in narrow ducts at depths of several metres.

Specifications

- Pressure Ranges : 0…1 to 0…5 bar

- Accuracy: ±0,5 %FS

- Pressure Connection: 4F / 5F / 6F / 8F

- Dimensions: ø 1,33…2,67 mm

- Temperature Range: 20...40 °C

Pressure Transmitters

- Pressure transmitters are sensors that use additional electronics to compensate for linearity deviations and temperature errors, outputting measurement results as standardised signals. Every transmitter is measured over the entire pressure and temperature profile and compared to the desired signal span.

Standard Pressure Transmitters

Series 21C

-

The pressure transmitters of the 21C series with ratiometric 0,5...4,5V output combine chip-in-oil measuring cells with conventional electrical connections and pressure connections, making them ideal for industrial use. The transmitters are extremely resistant to environmental influences and deliver accurate measurement results over a temperature range of -40 °C to 125 °C.

Specifications

- Pressure Ranges : 0…2 to 0…1000 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±1,5 %FS @ -10…80 °C

- Interfaces: 0,5…4,5V ratiom.

- Temperature Range: - 40...125 °C

Series 21Y

-

The pressure transmitters of the 21Y series have no internal seal and a high insulation voltage of 300 VDC, and are extremely resistant to environmental influences. The sophisticated compensation circuit makes it possible to specify a narrow total error band. A wide range of pressure connections and electrical connections are available to choose from.

Specifications

- Pressure Ranges : 0…2 to 0…1000 bar

- Accuracy: ±0,5 %FS

- Total Error Band: ±1,5 %FS @ -10…80 °C

- Interfaces:4…20 mA, 0…10V

- Temperature Range: - 40...100 °C

Series 23SY

-

The pressure transmitters of the 23SY series are designed for elevated requirements in industrial applications. Thanks to its modular concept, this series is highly flexible and makes it possible to realise customer-specific requirements in very little time. The sophisticated compensation circuit makes it possible to specify a narrow total error band.

Specifications

- Pressure Ranges : 0…0,1 to 0…1000 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,7 %FS @ -10…80 °C

- Interfaces: 4…20 mA, 0…10 V

- Temperature Range: - 40...100 °C

Series 33X

-

The pressure transmitters of the 33X series use digital compensation with a mathematical model to achieve exceptional accuracy of 0,05 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. Additional measurements and selections can optionally be used to achieve a precision (and also, if calibrated in an accredited test laboratory, an accuracy) of 0,01 %FS. In addition to the digital RS485 interface, the X-line transmitters have a rangeable, analog current or voltage output.

Specifications

- Pressure Ranges : 0…0,3 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @ -10…80 °C

- Interfaces: RS485, 4…20 mA, 0…10 V

- Temperature Range: - 40...120 °C

Series 23SX

-

In the 23SX series high-precision pressure transmitters, temperature dependencies and non-linearity are precisely compensated for by means of a mathematical model in the microcontroller. In addition to the RS485 interface with Modbus RTU protocol, there is also the option of outputting the measurement results as a scalable analogue signal via the integrated D/A converter. The fully welded construction without internal seals is suitable for dynamic applications. Only stainless steel is in contact with the media.

Specifications

- Pressure Ranges : 0…0,16 to 0…1000 bar

- Accuracy: ±0,1 %FS

- Total Error Band: ±0,25 %FS @ -10…80 °C

- Interfaces: RS485, 4…20 mA, 0…10 V

- Temperature Range: - -40…125 °C

Series 21PY

-

The compact pressure transmitters of the 21PY series with 0,5...4,5V output have a diameter of just 15 mm and weigh in at less than 20 g. The sophisticated compensation circuit makes it possible to specify a narrow total error band.

Specifications

- Pressure Ranges : 0…10 to 0…600 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,7 %FS @ -10…80 °C

- Interfaces: 0,5…4,5 V

- Temperature Range: - 20...100 °C

- Special characteristics: Small and lightweight

- Homologation: none

Series 41X

-

The capacitive pressure transmitters of the 41X series are designed for measuring relative pressure values in the mbar and µbar range. They use digital compensation with a mathematical model to achieve an accuracy of 0,1 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. In addition to the digital RS485 interface, the X-line transmitters have a rangeable analog current or voltage output.

Specifications

- Pressure Ranges : 0…0,03 to 0…0,3 bar

- Accuracy: ±0,1 %FS

- Total Error Band: ±0,2 %FS @ 10…50 °C

- Interfaces: RS485, 4…20 mA, 0…10V

- Temperature Range: -20…80 °C

IO-Link and CANopen Pressure Transmitters

Series 21Zio

-

The compact pressure transmitters of the 21Zio series can be used both as a pressure measuring instrument and as a pressure switch. Thanks to the universal IO-Link interface according to IEC 61131-9, the sensor is flexible and easily and quickly integrable into intelligent automation and other systems. The switching functions and other parameters can be called up and configured directly via IO-Link. In this way, machine downtimes are reduced to a minimum and personnel are relieved.

Specifications

- Pressure Ranges :0…4 to 0…1000 bar

- Accuracy: ±0,5 %FS

- Total Error Band: ±1,5 %FS @ -10…80 °C

- Interfaces: IO-Link

- Temperature Range: --40…125 °C °C

Series 23SXc

-

In the 23SXc series high-precision pressure transmitters, temperature dependencies and non-linearity are precisely compensated for by means of a mathematical model in the microcontroller. With the CANopen interface, KELLER offers a highly accurate pressure transmitter that is optimally suited for a wide variety of automation solutions. The fully welded construction without internal seals is suitable for dynamic applications. Only stainless steel is in contact with the media.

Specifications

- Pressure Ranges : 0…0,16 to 0…1000 bar

- Accuracy: ±0,1 %FS

- Total Error Band: ±0,25 %FS @ -10…80 °C

- Interfaces: CANopen

- Temperature Range: - -40…125 °C

Front-Flush Pressure Transmitters

Series 25Y

-

The pressure transmitters of the 25Y series with a front-flush separating diaphragm are designed for elevated requirements in industrial applications and are supplied with a G1/2" male pressure port. Thanks to its modular concept, this series is highly flexible and makes it possible to realise customer-specific requirements in very little time. The sophisticated compensation circuit makes it possible to specify a narrow total error band.

Specifications

- Pressure Ranges : 0…0,5 to 0…1000 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,7 %FS @ -10…80 °C

- Interfaces: 4…20 mA, 0…10 V

- Temperature Range: - 40...100 °C

- Intrinsic safety: Series 25YEi

Series 35X

-

The front-flush pressure transmitters of the 35X series use digital compensation with a mathematical model to achieve exceptional accuracy of 0,05 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. In addition to the digital RS485 interface, the X-line transmitters have a rangeable, analog current or voltage output.

Specifications

- Pressure Ranges : 0…0,3 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @ -10…80 °C

- Interfaces: RS485, 4…20 mA, 0…10 V

- Temperature Range: - 40...120 °C

Series 35XHT

-

The pressure transmitters of the 35XHT series are suitable for use in media temperatures up to 150 °C and can therefore be used in bioreactors and autoclaves that have to be sterilised regularly. They use digital compensation with a mathematical model to achieve an accuracy of 0,15 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. In addition to the digital RS485 interface, the X-line transmitters have a rangeable, analog current or voltage output. The standard model of the 35XHT series has an Ingold fitting as pressure connection.

Specifications

- Pressure Ranges : 0…1 to 0…30 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,15 %FS @ 20…200 °C

- Interfaces: RS485, 4…20 mA, 0…10 V

- Temperature Range: - 20...150 °C

Series 35XHTC

-

The high-temperature pressure transmitters of the 35XHTC series can be used at media temperatures of up to 300 °C. The remote electronics are designed for temperatures of up to 120 °C. They use digital compensation with a mathematical model to achieve an accuracy of 0,5 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. In addition to the digital RS485 interface, the X-line transmitters have a rangeable, analog current or voltage output. The standard model of the 35XHTC series has a G1/2 thread as pressure connection.

Specifications

- Pressure Ranges : 0…3 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,5 %FS @ -10…80 °C

- Interfaces :RS485, 4…20 mA, 0…10 V

- Temperature Range: 0...300 °C

Series 35XHTT

-

The pressure transmitters of the 35XHTT series are suitable for use in media temperatures up to 150 °C and can therefore be used in bioreactors and autoclaves that have to be sterilised regularly. They use digital compensation with a mathematical model to achieve an accuracy of 0,15 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. The standard model of the 35XHTT series has a G1/2 thread as pressure connection.

Specifications

- Pressure Ranges : 0…1 to 0…30 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,15 %FS @ 20…120 °C

- Interfaces: RS485, 4…20 mA, 0…10 V

- Temperature Range: -20…150 °C

High-Temperature Pressure Transmitters

Series M5HB

-

The ultra-fast M5HB pressure transmitter can process pressure changes with a bandwidth of 50 kHz. This is achieved by means of the continuous analog signal that is adjusted by a digital circuit in real time and is amplified to a standardised 0...10V signal. The miniature sensor head with a fine M5 thread can withstand temperatures of up to 180 °C, is overload-proof up to a magnitude of five times the measuring range, and is also resistant to vibrations.

Specifications

- Pressure Ranges : 0…3 to 0…30 bar

- Accuracy: ±0,1 %FS

- Total Error Band: ±0,5 %FS @ -20…125 °C

- Interfaces : 0…10 V

- Temperature Range: -40…180 °C

Series M8coolHB

-

The ultra-fast M8coolHB pressure transmitter can process pressure changes with a bandwidth of 50 kHz. This is achieved by means of the continuous analog signal that is adjusted by a digital circuit in real time and is amplified to a standardised 0...10V signal. The miniature sensor head with a fine M8 thread can withstand temperatures of up to 1000 °C with suitable cooling, is overload-proof up to a magnitude of five times the measuring range, and is also resistant to vibrations.

Specifications

- Pressure Ranges : 0…3 to 0…30 bar

- Accuracy: ±0,1 %FS

- Total Error Band: ±1,0 %FS @ -40…180 °C

- Interfaces : 0…10 V

- Temperature Range: -50…1000 °C

Series 35XHTC

-

The high-temperature pressure transmitters of the 35XHTC series can be used at media temperatures of up to 300 °C. The remote electronics are designed for temperatures of up to 120 °C. They use digital compensation with a mathematical model to achieve an accuracy of 0,5 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. In addition to the digital RS485 interface, the X-line transmitters have a rangeable, analog current or voltage output. The standard model of the 35XHTC series has a G1/2 thread as pressure connection.

Specifications

- Pressure Ranges : 0…3 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,5 %FS @ -10…80 °C

- Interfaces :RS485, 4…20 mA, 0…10 V

- Temperature Range: 0...300 °C

Series 9LC

-

The pressure transmitters of the 9LC series use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy C-276. The transmitters are extremely resistant to environmental influences and deliver compensated measurement results as an analog, ratiometric 0,5...4,5V output signal over a wide temperature range.

Specifications

- Pressure Ranges : 0…1 to 0…1000 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,8 %FS @ -10…80 °C

- Interfaces: 0,5…4,5V ratiom.

- Temperature Range: - 40...150 °C

Series 35XHT

-

The pressure transmitters of the 35XHT series are suitable for use in media temperatures up to 150 °C and can therefore be used in bioreactors and autoclaves that have to be sterilised regularly. They use digital compensation with a mathematical model to achieve an accuracy of 0,15 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. In addition to the digital RS485 interface, the X-line transmitters have a rangeable, analog current or voltage output. The standard model of the 35XHT series has an Ingold fitting as pressure connection.

Specifications

- Pressure Ranges : 0…1 to 0…30 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,15 %FS @ 20…200 °C

- Interfaces: RS485, 4…20 mA, 0…10 V

- Temperature Range: - 20...150 °C

Series 35XHTT

-

The pressure transmitters of the 35XHTT series are suitable for use in media temperatures up to 150 °C and can therefore be used in bioreactors and autoclaves that have to be sterilised regularly. They use digital compensation with a mathematical model to achieve an accuracy of 0,15 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. The standard model of the 35XHTT series has a G1/2 thread as pressure connection.

Specifications

- Pressure Ranges : 0…1 to 0…30 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,15 %FS @ 20…120 °C

- Interfaces: RS485, 4…20 mA, 0…10 V

- Temperature Range: -20…150 °C

Differential Pressure Transmitters

Series PD-33X

-

The differential pressure transmitters of the PD-33X series are suitable for 'wet/wet' applications. They have a single silicon diaphragm in their interior, which is pressurised from both sides and measures the pressure difference directly. This design enables them to measure small pressure differences even at an extremely high line pressure. The transmitters use digital compensation with a mathematical model to achieve exceptional accuracy of 0,05 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band.

Specifications

- Pressure Ranges : 0…0,3 to 0…30 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @-10…80 °C

- Line pressure: 200 bar / 600 bar

- Interfaces: RS485, 4…20 mA, 0…10 V

- Special characteristics: Classic 'wet/wet'

Series PD-39X

-

The differential pressure transmitters of the PD-39X series measure the pressure difference indirectly using two absolute pressure sensors. The dual-sensor design with numerical differential formation also outputs the line pressure values via the digital RS485 interface and guarantees a high overload resistance. The additional analog current or voltage output is primarily used to output the differential pressure range, which is freely rangeable within the line pressure range.

Specifications

- Pressure Ranges : 0…0,3 to 0…30 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @-10…80 °C

- Line pressure: 0…3 to 0…300 bar

- Interfaces: RS485, 4…20 mA, 0…10 V

- Special characteristics: Line pressure measurement

Series PRD-33X

-

The differential pressure transmitters of the PRD-33X series are designed for accurate measurements in low pressure ranges with very high overload on both sides. In addition to the differential pressure sensor, which may only be exposed to gases at its rear face, the devices have an additional absolute pressure sensor that measures the line pressure. Both measured values are output via the digital RS485 interface and are the ideal basis for cryogenic tank monitoring.

Specifications

- Pressure Ranges : 0…0,35 to 0…3 bar

- Accuracy: ±0,1 %FS

- Total Error Band: ± 0,3 %FS @ -30…60 °C

- Line pressure: 0…40 bar

- Interfaces: RS485

- Special characteristics: Line pressure measurement

Series PD-41X

-

The capacitive pressure transmitters of the PD-41X series are designed for measuring differential pressure values in the mbar and µbar range. They use digital compensation with a mathematical model to achieve an accuracy of 0,1 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. In addition to the digital RS485 interface, the X-line transmitters have a rangeable analog current or voltage output.

Specifications

- Pressure Ranges : 0…0,03 to 0…0,3 bar

- Accuracy: ±0,1 %FS

- Total Error Band: ± 0,2 %FS @ 10…50 °C

- Line pressure: 2 bar

- Interfaces: RS485, 4…20 mA, 0…10 V

- Special characteristics: Capacitive sensor

Automotive Pressure Transmitters

Series 22M

-

The pressure transmitters of the 22M series with brass housing were designed to be a reliable solution for automotive and industrial applications. They are homologated and can be used, for instance, to measure the content of the gas tank in bivalent vehicles.

Specifications

- Pressure Ranges : 0…5 to 0…250 bar

- Total Error Band: ±2,0 %FS @ 0…80 °C

- Interfaces: 0,5…4,5 V ratiom., 4...20 mA

- Special characteristics: Brass

- Homologation: E4-110R, E4-10R

Series 22DT

-

The 22DT series has been specially developed for use in bivalent vehicles (volume flow measurement when running on natural gas) and is homologated for the automotive industry. However, it also has other industrial applications. The NTC or PT temperature sensor located directly beneath the steel diaphragm reacts more quickly to temperature changes thanks to its special design. The pressure transmitters are protected against electromagnetic fields up to 200 V/m and output the measured values as a ratiometric 0,5...4,5V analog signal. The connections of the temperature sensor are fed out directly.

Specifications

- Pressure Ranges : 0…14 bar

- Total Error Band: ±2,0 %FS @ 0…90 °C

- Interfaces: 0,5…4,5 V ratiom.

- Special characteristics: With temperature sensor

- Homologation: E4-110R, E4-10R

Series 21PY

-

The compact pressure transmitters of the 21PY series with 0,5...4,5V output have a diameter of just 15 mm and weigh in at less than 20 g. The sophisticated compensation circuit makes it possible to specify a narrow total error band.

Specifications

- Pressure Ranges : 0…10 to 0…600 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,7 %FS @ -10…80 °C

- Interfaces: 0,5...4,5 V

- Temperature Range: - 20...100 °C

- Special characteristics: Small and lightweight

- Homologation: none

Series 21PHB

-

The highly dynamic and compact 21PHB pressure transmitter is suitable for use in liquids and gases, and can process pressure changes with a bandwidth of 20 kHz. This is achieved by means of the continuous analog signal that is adjusted by a digital circuit in real time and is amplified to a standardised 0...10V signal. The miniature sensor head with a fine M6 thread can withstand temperatures of up to 100 °C and is overload-proof up to a magnitude of four times the measuring range.

Specifications

- Pressure Ranges : 0…10 to 0…600 bar

- Total Error Band: ±0,5%FS @ -10…80 °C

- Interfaces: 0…10 V

- Special characteristics: 20kHz bandwidth

- Homologation: none

Series 22S

-

The pressure transmitters of the 22S series were designed for use in automotive and industrial applications. They are homologated and every one of their elements has been configured for optimum reliability. In this steel version of the 22 series, all parts that come into contact with media are made of stainless steel (AISI 316L).

Specifications

- Pressure Ranges : 0…5 to 0…250 bar

- Total Error Band: ±2,0 %FS @ 0…80 °C

- Interfaces: 0,5…4,5 V ratiom., 4...20 mA

- Special characteristics: Steel 316L

- Homologation: none

Series 22-PS

-

The programmable pressure switches of the 22-PS series are encased in a compact yet robust steel housing and are available with PNP or NPN wiring. The pressure switches can be supplied pre-configured at the customer's request. With the aid of the dV22-PP programming unit (available for purchase separately), the two switch outputs can be programmed at any time to be normally closed or normally open at a range of switching points with a window or hysteresis function.

Specifications

- Pressure Ranges : 0…4 to 0…400 bar

- Total Error Band: ±2,0 %FS @ 0…80 °C

- Interfaces: 0,5…4,5 V, 2 switch outputs

- Special characteristics: Programmable pressure switch

- Homologation: none

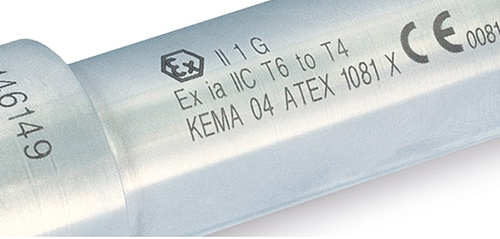

Intrinsically Safe Pressure Transmitters

Series 23SY-Ei

-

The pressure transmitters of the 23SY-Ei series are designed for elevated requirements in industrial applications. Thanks to its modular concept, this series is highly flexible and makes it possible to realise customer-specific requirements in very little time. The sophisticated compensation circuit makes it possible to specify a narrow total error band.

Specifications

- Pressure Ranges : 0…0,1 to 0…1000 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,7 %FS @ -10…80 °C

- Interfaces: 4…20 mA, 0…10 V

- Temperature Range: - 40...100 °C

Series 25Y-Ei

-

The pressure transmitters of the 25Y-Ei series with a front-flush separating diaphragm are designed for elevated requirements in industrial applications and are supplied with a G1/2" male pressure port. Thanks to its modular concept, this series is highly flexible and makes it possible to realise customer-specific requirements in very little time. The sophisticated compensation circuit makes it possible to specify a narrow total error band.

Specifications

- Pressure Ranges : 0…0,5 to 0…1000 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,7 %FS @ -10…80 °C

- Interfaces: 4…20 mA, 0…10 V

- Temperature Range: - 40...100 °C

Series 33X-Ei

-

The pressure transmitters of the 33X-Ei series use digital compensation with a mathematical model to achieve exceptional accuracy of 0,05 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. Additional measurements and selections can optionally be used to achieve a precision (and also, if calibrated in an accredited test laboratory, an accuracy) of 0,01 %FS. In addition to the digital RS485 interface, the X-line transmitters have a rangeable, analog current or voltage output.

Specifications

- Pressure Ranges : 0…0,3 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @ -10…80 °C

- Interfaces: RS485, 4…20 mA, 0…10 V

- Temperature Range: - 40...120 °C

Series 35X-Ei

-

The front-flush pressure transmitters of the 35X-Ei series use digital compensation with a mathematical model to achieve exceptional accuracy of 0,05 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. In addition to the digital RS485 interface, the X-line transmitters have a rangeable, analog current or voltage output.

Specifications

- Pressure Ranges : 0…0,3 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @ -10…80 °C

- Interfaces: RS485, 4…20 mA, 0…10 V

- Temperature Range: - 40...120 °C

Series PD-33X-Ei

-

The differential pressure transmitters of the PD-33X-Ei series are suitable for 'wet/wet' applications. They have a single silicon diaphragm in their interior, which is pressurised from both sides and measures the pressure difference directly. This design enables them to measure small pressure differences even at an extremely high line pressure. The transmitters use digital compensation with a mathematical model to achieve exceptional accuracy of 0,05 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. Intrinsically safe – suitable for use in explosive atmospheres.

Specifications

- Pressure Ranges : 0…0,3 to 0…30 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @-10…80 °C

- Line pressure: 200 bar / 600 bar

- Interfaces: RS485, 4…20 mA, 0…10 V

- Special characteristics: Classic 'wet/wet'

Series PD-39X-Ei

-

The differential pressure transmitters of the PD-39X-Ei series measure the pressure difference indirectly using two absolute pressure sensors. The dual-sensor design with numerical differential formation also outputs the line pressure values via the digital RS485 interface and guarantees a high overload resistance. The additional analog current or voltage output is primarily used to output the differential pressure range, which is freely rangeable within the line pressure range.

Specifications

- Pressure Ranges : 0…0,3 to 0…30 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @-10…80 °C

- Line pressure: 0…3 to 0…300 bar

- Interfaces: RS485, 4…20 mA, 0…10 V

- Special characteristics: Line pressure measurement

Series 41X-Ei

-

The capacitive pressure transmitters of the 41X-Ei series are designed for measuring relative pressure values in the mbar and µbar range. They use digital compensation with a mathematical model to achieve an accuracy of 0,1 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. In addition to the digital RS485 interface, the X-line transmitters have a rangeable analog current or voltage output.

Specifications

- Pressure Ranges : 0…0,03 to 0…0,3 bar

- Accuracy: ±0,1 %FS

- Total Error Band: ±0,2 %FS @ 10…50 °C

- Interfaces: RS485, 4…20 mA, 0…10V

- Temperature Range: -20…80 °C

Flame Proof Pressure Transmitters

Series 33X-Ed

-

The pressure transmitters of the 33X-Ed series use digital compensation with a mathematical model to achieve exceptional accuracy of 0,05 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. Additional measurements and selections can optionally be used to achieve a precision (and also, if calibrated in an accredited test laboratory, an accuracy) of 0,01 %FS. In addition to the digital RS485 interface, the X-line transmitters have a rangeable, analog current or voltage output. Pressure-proof housing – suitable for use in explosive atmospheres.

Specifications

- Pressure Ranges : 0…0,3 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @ -10…80 °C

- Interfaces: RS485, 4…20 mA, 0…10 V

- Temperature Range: - 40...120 °C

Series 35X

-

The front-flush pressure transmitters of the 35X-Ed series use digital compensation with a mathematical model to achieve exceptional accuracy of 0,05 %FS – in the temperature range from 10 to 40 °C, this value even corresponds to the total error band. In addition to the digital RS485 interface, the X-line transmitters have a rangeable, analog current or voltage output.

Specifications

- Pressure Ranges : 0…0,3 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @ -10…80 °C

- Interfaces: RS485, 4…20 mA, 0…10 V

- Temperature Range: - 40...120 °C

Series 23-Ed

-

The series 23-Ed pressure transmitters are designed for industrial applications and are based on the highly stable pressure transducers of the 10L series and a fully analog circuit. Thanks to its modular concept, this series can be flexibly adapted to customer-specific pressure connections and connector plugs.

Specifications

- Pressure Ranges : 0…0,2 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±4,0 %FS @ -10…80 °C

- Interfaces: 4…20 mA, 0…10 V

- Temperature Range: - 40...100 °C

Series 25-Ed

-

The series 25-Ed pressure transmitters with a front-flush separating diaphragm are designed for industrial applications and are supplied with a G1/2" or G3/4" male pressure port. They are based on a fully analog circuit. Pressure-proof housing – suitable for use in explosive atmospheres.

Specifications

- Pressure Ranges : 0…0,5 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±4,0 %FS @ -10…80 °C

- Interfaces: 4…20 mA, 0…10 V

- Temperature Range: - 40...100 °C

OEM Pressure Transmitters

Series 4LC

-

The pressure transmitters of the 4LD series use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy. The transmitters are extremely resistant to environmental influences and delivery highly accurate measurement results as a digital output signal. The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions.

Specifications

- Pressure Ranges: 0…10 to 0…200 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±1,0 %FS @ 0…50 °C

- Interfaces: 0,5…4,5 V ratiom.

- Dimensions: ø 11 mm x 4,2 mm

Series 7LD

-

The pressure transmitters of the 7LD series use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy. The transmitters are extremely resistant to environmental influences and delivery highly accurate measurement results as a digital output signal. The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions.

Specifications

- Pressure Ranges: 0…3 to 0…200 bar

- Accuracy: ±0,15 %FS

- Total Error Band: ±0,7 %FS @ -10…80 °C

- Interfaces: I2C

- Dimensions: ø 15 mm x 5 mm

Series 9FLC

-

The 9FLC series is a special version of the 9LC pressure transmitter. The flanged housing can be mounted using an O-ring or welded on. As with all C-line products, the chip-in-oil technology developed by KELLER Pressure is used here, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy. The transmitters are extremely resistant to environmental influences and deliver highly accurate measurement results as an analog, ratiometric 0,5...4,5V output signal over a temperature range of -40 °C to 150 °C.

Specifications

- Pressure Ranges: 0…1 to 0…50 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,8 %FS @ -10…80 °C

- Interfaces: 0,5…4,5 V ratiom.

- Dimensions: ø 17 mm x 5,5 mm

Series 9LD

-

The pressure transmitters of the 9LD series use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy. The transmitters are extremely resistant to environmental influences and delivery highly accurate measurement results as a digital output signal. The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions.

Specifications

- Pressure Ranges: 0…1 to 0…200 bar

- Accuracy: ±0,15 %FS

- Total Error Band: ± ±0,7 %FS @ -10…80 °C

- Interfaces: I2C

- Temperature Range: - 40...110 °C

- Dimensions: ø 19 mm x 5 mm

Series 4LD

-

The pressure transmitters of the 4LD series use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy. The transmitters are extremely resistant to environmental influences and delivery highly accurate measurement results as a digital output signal. The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions.

Specifications

- Pressure Ranges: 0…3 to 0…200 bar

- Accuracy: ±0,15 %FS

- Total Error Band: ±0,7 %FS @ 0…50 °C

- Interfaces: I2C

- Dimensions: ø 11 mm x 4,2 mm

Series 7LC

-

The pressure transmitters of the 4LC series use the chip-in-oil developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy. The transmitters are extremely resistant to environmental influences and deliver compensated measurement results as an analog, ratiometric 0,5...4,5V output signal over a wide temperature range.

Specifications

- Pressure Ranges: 0…2 to 0…200 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±1,0 %FS @ -10…80 °C

- Interfaces: 0,5…4,5 V ratiom.

- Dimensions: ø 15 mm x 5 mm

Series 9FLD

-

The 9FLD series is a special version of the 9LD pressure transmitter. The flanged housing can be mounted using an O-ring or welded on. As with all D-line products, the chip-in-oil technology developed by KELLER is used here, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy.The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions.

Specifications

- Pressure Ranges: 0…1 to 0…30 bar

- Accuracy: ±0,15 %FS

- Total Error Band: ±0,7 %FS @ -10…80 °C

- Interfaces: I2C

- Dimensions: ø 17 mm x 5,5 mm

Series 9LC

-

The pressure transmitters of the 9LC series use the chip-in-oil developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy. The transmitters are extremely resistant to environmental influences and deliver compensated measurement results as an analog, ratiometric 0,5...4,5V output signal over a wide temperature range.

Specifications

- Pressure Ranges: 0…1 to 0…200 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,8 %FS @ -10…80 °C

- Interfaces: 0,5…4,5 V ratiom.

- Dimensions: ø 19 mm x 5 mm

Series 8LC

-

The pressure transmitters of the 8LC series use the chip-in-oil developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy. The transmitters are extremely resistant to environmental influences and deliver compensated measurement results as an analog, ratiometric 0,5...4,5V output signal over a wide temperature range.

Specifications

- Pressure Ranges: 0…1 to 0…200 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,8 %FS @ -10…80 °C

- Interfaces: 0,5…4,5 V ratiom.

- Dimensions: ø 17 mm x 7 mm

Series 10LX

-

The OEM pressure transmitters of the 10LX series by KELLER are a combination of a pressure transducer from the Series 10L and the tried and tested X-line electronics. Both temperature dependence and non-linearity are precisely compensated for in the microcontroller by means of a mathematical model, thereby achieving the highest degree of accuracy. The 10LX owes its versatility to its compact design and robust stainless steel housing, which mean it can be used in a wide range of OEM applications.

Specifications

- Pressure Ranges: 0…0,3 to 0…200 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @ -10…80 °C

- Interfaces: RS485, 4…20 mA, 0…10 V

- Dimensions: ? 19mm x 57…96 mm

OEM High-Pressure Transmitters

Series 6LHPC

-

The high-pressure transmitters of the 6LHPC series use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Inconel. The transmitters are extremely resistant to environmental influences and deliver compensated measurement results as an analog, ratiometric 0,5...4,5V output signal over a wide temperature range.

Specifications

- Pressure Ranges: 0…200 to 0…1000 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,8 %FS @ -10…80 °C

- Interfaces: 0,5…4,5V ratiom.

- Dimensions: ø 13 mm x 8 mm

Series 7LHPC

-

The high-pressure transmitters of the 7LHPC series use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Inconel. The transmitters are extremely resistant to environmental influences and deliver compensated measurement results as an analog, ratiometric 0,5...4,5V output signal over a wide temperature range.

Specifications

- Pressure Ranges: 0…200 to 0…1000 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,8 %FS @ -10…80 °C

- Interfaces: 0,5...4,5V ratiom.

- Dimensions: ø 15 mm x 8 mm

Series 6LHPD

-

The pressure transmitters of the 6LHPD series for high pressure applications use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Inconel. The transmitters are extremely resistant to environmental influences and delivery highly accurate measurement results as a digital output signal. The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions.

Specifications

- Pressure Ranges: 0…400 to 0…1000 bar

- Accuracy: ±0,15 %FS

- Total Error Band: ±1,0 %FS @ -10…80 °C

- Interfaces: I2C

- Dimensions: ø 13 mm x 8 mm

Series 7LHPD

-

The pressure transmitters of the 7LHPD series for high pressure applications use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Inconel. The transmitters are extremely resistant to environmental influences and delivery highly accurate measurement results as a digital output signal. The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions.

Specifications

- Pressure Ranges: 0…400 to 0…1000 bar

- Accuracy: ±0,15 %FS

- Total Error Band: ±1,0 %FS @ -10…80 °C

- Interfaces: I2C

- Dimensions: ø 15 mm x 8 mm

- Intrinsic safety: Series 7LDEi

Intrinsically Safe OEM Pressure Transmitters

Series 4LD-Ei

-

The pressure transmitters of the 4LD-Ei series use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy. The transmitters are extremely resistant to environmental influences and delivery highly accurate measurement results as a digital output signal. The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions. Intrinsically safe – suitable for use in explosive atmospheres.

Specifications

- Pressure Ranges: 0…3 to 0…200 bar

- Accuracy: ±0,15 %FS

- Total Error Band: ±0,7 %FS @ 0…50 °C

- Interfaces: I2C

- Dimensions: ø 11 mm x 4,2 mm

Series 6LHPD-Ei

-

The pressure transmitters of the 6LHPD-Ei series for high pressure applications use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Inconel. The transmitters are extremely resistant to environmental influences and delivery highly accurate measurement results as a digital output signal. The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions.

Specifications

- Pressure Ranges: 0…400 to 0…1000 bar

- Accuracy: ±0,15 %FS

- Total Error Band: ±1,0 %FS @ -10…80 °C

- Interfaces: I2C

- Dimensions: ø 13 mm x 8 mm

Series 7LD-Ei

-

The pressure transmitters of the 7LD-Ei series use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy. The transmitters are extremely resistant to environmental influences and delivery highly accurate measurement results as a digital output signal. The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions.

Specifications

- Pressure Ranges: 0…3 to 0…200 bar

- Accuracy: ±0,15 %FS

- Total Error Band: ±0,7 %FS @ -10…80 °C

- Interfaces: I2C

- Dimensions: ø 15 mm x 5 mm

Series 7LHPD-Ei

-

The pressure transmitters of the 7LHPD-Ei series for high pressure applications use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Inconel. The transmitters are extremely resistant to environmental influences and delivery highly accurate measurement results as a digital output signal. The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions.

Specifications

- Pressure Ranges: 0…400 to 0…1000 bar

- Accuracy: ±0,q5 %FS

- Total Error Band: ±1,0 %FS @ -10…80 °C

- Interfaces: I2C

- Dimensions: ø 15 mm x 8 mm

Series 9LD-Ei

-

The pressure transmitters of the 9LD-Ei series use the chip-in-oil technology developed by KELLER Pressure, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy. The transmitters are extremely resistant to environmental influences and delivery highly accurate measurement results as a digital output signal. The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions.

Specifications

- Pressure Ranges: 0…1 to 0…200 bar

- Accuracy: ±0,15 %FS

- Total Error Band: ±0,7 %FS @ -10…80 °C

- Interfaces: I2C

- Temperature Range: - 40...110 °C

- Dimensions: ø 19 mm x 5 mm

Series 9FLD-Ei

-

The 9FLD-Ei series is a special version of the 9LD-Ei pressure transmitter. The flanged housing can be mounted using an O-ring or welded on. As with all D-line products, the chip-in-oil technology developed by KELLER Pressure is used here, uniting a pressure measuring cell, digital temperature compensation and signal processing in a compact housing made of stainless steel or Hastelloy.The I2C interface and the low supply voltages make it easy to integrate in microcontroller-based systems. The extremely low power consumption is ideal for battery-operated devices. The D line is perfect for IoT solutions.

Specifications

- Pressure Ranges: 0…1 to 0…30 bar

- Accuracy: ±0,15 %FS

- Total Error Band: ±0,7 %FS @ -10…80 °C

- Interfaces: I2C

- Dimensions: ø 17 mm x 5,5 mm

Analog Pressure Transmitters

Series 23

-

The series 23 pressure transmitters are designed for industrial applications and are based on the highly stable pressure transducers of the 10L series and a fully analog circuit. Thanks to its modular concept, this series can be flexibly adapted to customer-specific pressure connections and connector plugs.

Specifications

- Pressure Ranges : 0…0,2 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±4,0 %FS @ -10…80 °C

- Interfaces: 4…20 mA, 0…10 V

- Temperature Range: - 40...100 °C

- Pressure-resistant encapsulation: Serie 23Ed

Series 25

-

The series 25 pressure transmitters with a front-flush separating diaphragm are designed for industrial applications and are supplied with a G1/2" or G3/4" male pressure port. They are based on a fully analog circuit.

Specifications

- Pressure Ranges : 0…0,5 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±4,0 %FS @ -10…80 °C

- Interfaces: 4…20 mA, 0…10 V

- Temperature Range: - 40...100 °C

Series PD-23

-

The differential pressure transmitters of the PD-23 series are designed for industrial applications and are supplied with a G1/4 internal thread as standard. They are based on a fully analog circuit. The PD-23 transmitters have a single silicon diaphragm in their interior, which is pressurised from both sides and measures the pressure difference directly. This design enables them to measure tiny pressure differences even at an extremely high line pressure.

Specifications

- Pressure Ranges : 0…0,2 to 0…20 bar

- Accuracy: ±0,5 %FS

- Total Error Band: ±4,0 %FS @ -10…80 °C

- Line pressure: 200 bar

- Interfaces: 4…20 mA, 0…10 V

- Temperature Range -40…100 °C

- Special characteristics: Classic 'wet/wet'

Level Probes

- Submersible probes for level and fill measurement. With a special design and cable and housing materials that have been chosen for compatibility with their surroundings, these probes can be used in a wide range of liquids.

Standard Level Probes

Series 36XW

-

In the high-precision level sensors of the 36XW series, the temperature dependence and nonlinearity are precisely compensated for in the microcontroller by means of a mathematical model. In addition to the RS485 interface, the measurement results can also be output via the integrated D/A converter as a rangeable analog signal. Extended lightning protection is also available as an option.

Specifications

- Pressure Ranges : 0…0,3 to 0…30 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @ 0…50 °C

- Interfaces : RS485, 4…20 mA, 0…10 V

- Special characteristics: Optimum accuracy

Series 26Y

-

The level sensors of the 26Y series are budget-friendly, but still offer high accuracy and excellent long-term stability. They are available in versions for absolute or relative pressure. With a start-up time of just 5 ms, the Y line is ideally suited to data logger applications.

Specifications

- Pressure Ranges : 0…0,1 to 0…10 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,5 %FS @ 0…50 °C

- Interfaces : 4…20 mA, 0…10 V

- Special characteristics: Compact design

Series 36KyX

-

The 36KyX series was specially developed for brackish water and sewage applications. It is equipped with a non-fouling Kynar separating diaphragm, which combines the anti-adhesion properties of PTFE with outstanding hardness and abrasion resistance. This level sensors design can be readily installed in harsh environments, eliminating the need for bulky, costly protective equipment. In addition to the RS485 interface, the measurement results can also be output via the integrated D/A converter as a rangeable analog signal.

Specifications

- Pressure Ranges : 0…1 to 0…10 bar

- Accuracy: ±0,3 %FS

- Total Error Band: ±0,5 %FS @ 0…50 °C

- Interfaces : RS485, 4…20 mA, 0…10 V

- Special characteristics: Plastic diaphragm

Series 46X

-

The level sensors of the 46X series combine a ceramic measuring cell for very low measuring ranges on the mbar scale with microprocessor electronics for compensating for temperature dependence and nonlinearity. In addition to the digital RS485 interface, the sensors also have a rangeable analog output.

Specifications

- Pressure Ranges : 0…0,03 to 0…0,3 bar

- Accuracy: ±0,1 %FS

- Total Error Band: ±0,2 %FS @ 10…50 °C

- Interfaces : RS485, 4…20 mA, 0…10 V

- Special characteristics: Ceramic measuring cell

Series 36XiW

-

The high-precision level sensors of the 36XiW series measure with ultra-high accuracy and resolution. Temperature dependence and nonlinearity are precisely compensated for in the microprocessor by means of a mathematical model. They can be supplied with either an RS485 or SDI-12 interface. In addition to the pressure sensor for the level measurement, it is also possible to integrate a Pt1000 that is calibrated to ±0,1 °C from 0...50 °C. Extended lightning protection comes as standard with the SDI-12 interface and is available as an option for the RS485 interface.

Specifications

- Pressure Ranges : 0…1 to 0…10 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @ 0…50 °C

- Interfaces : RS485, SDI-12

- Special characteristics: Maximum resolution

Series 36XS

-

With a small diameter of just 16 mm, these level sensors are ideally suited to use in small spaces, such as narrow monitoring pipes. The measurement results can be read out via the 4...20 mA output or the RS485 interface. Extended lightning protection is integrated as standard.

Specifications

- Pressure Ranges : 0…1 to 0…30 bar

- Accuracy: ±0,3 %FS

- Total Error Band: ±0,5 %FS @ 0…50 °C

- Interfaces : RS485, 4…20 mA, 0…10 V

- Special characteristics: Plastic diaphragm

Intrinsically Safe Level Probes

Series 26Y-Ei

-

The level sensors of the 26Y-Ei series are budget-friendly, but still offer high accuracy and excellent long-term stability. They are available in versions for absolute or relative pressure. With a start-up time of just 5 ms, the Y line is ideally suited to data logger applications.

Intrinsically safe – suitable for use in explosive atmospheres.Specifications

- Pressure Ranges : 0…0,1 to 0…10 bar

- Accuracy: ±0,25 %FS

- Total Error Band: ±0,5 %FS @ 0…50 °C

- Interfaces : 4…20 mA, 0…10 V

- Special characteristics: Compact design

Series 36XW-Ei

-

In the high-precision level pressure transmitters of the 36XW-Ei series, the temperature dependence and nonlinearity are precisely compensated for in the microcontroller by means of a mathematical model. In addition to the RS485 interface, the measurement results can also be output via the integrated D/A converter as a rangeable analog signal. Extended lightning protection is also available as an option.

Intrinsically safe – suitable for use in explosive atmospheres.Specifications

- Pressure Ranges : 0…0,3 to 0…30 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @ 0…50 °C

- Interfaces : RS485, 4…20 mA, 0…10 V

- Special characteristics: Optimum accuracy

Series 46X-Ei

-

The level sensors of the 46X-Ei series combine a ceramic measuring cell for very low measuring ranges on the mbar scale with microprocessor electronics for compensating for temperature dependence and nonlinearity. In addition to the digital RS485 interface, the sensors also have a rangeable analog output.

Intrinsically safe – suitable for use in explosive atmospheres.Specifications

- Pressure Ranges : 0…0,03 to 0…0,3 bar

- Accuracy: ±0,1 %FS

- Total Error Band: ±0,2 %FS @ 10…50 °C

- Interfaces : RS485, 4…20 mA, 0…10 V

- Special characteristics: Ceramic measuring cell

Multi-Parameter Probes

Series 36XiW-CTD

-

The high-precision multi-parameter probes of the 36XiW-CTD series measure conductivity and temperature as well as pressure, along with the depth of bodies of water. Temperature dependence and nonlinearity are precisely compensated for in the microcontroller by means of a mathematical model. The integrated Pt1000 achieves an accuracy of ±0,1 °C, and the conductivity can be measured at ± 2,5% of the selected range (0,2 / 2 / 20 / 200 mS/cm). The sensors can be supplied with either an RS485 or SDI-12 interface. Extended lightning protection comes as standard with the SDI-12 and is available as an option for the RS485 interface.

Specifications

- Pressure Ranges : 0…0,3 to 0…30 bar

- Accuracy: ±0,05 %FS

- Total Error Band: 0,1 %FS @ 0…50 °C

- Interfaces : RS485, SDI-12

- Special characteristics: Additional conductivity measurement

Data Loggers

- A variety of data logger designs for recording the pressure and temperature profile. Depending on the system, the data is read out via a plug connection or via remote transfer.

Level Loggers

DCX-22

-

The DCX-22 data loggers achieve greater measurement accuracy than loggers with a smaller diameter. Thanks to their long-life battery, they can keep measuring the water level, water pressure and temperature for years (up to 10 years at a rate of one measurement per hour). The data logger can be configured using the supplied software (measurement interval, incident management, delayed measurement start etc.) and data that has been read can be displayed in a graph or chart, corrected using air pressure values, converted into fill levels or other units, and exported.

Specifications

- Pressure Ranges : 0…0,3 to 0…30 bar

- Total Error Band: 0,1 %FS @ 0…50 °C

- Reading capacity: 57'000 measuring points

- Dimensions : ø 22 mm

- Special characteristics: Also available in ECO design

DCX-22AA

-

The DCX-22AA data loggers compensate for changes in air pressure by means of a separate, water-tight absolute pressure sensor with a stainless steel separating diaphragm. Unlike gauge pressure systems with a capillary tube, this system is completely resistant to moisture and can therefore be immersed. Thanks to their long-life battery, they can keep measuring the water level, water pressure and temperature for years (up to 10 years at a rate of one measurement per hour). The logger can be configured using the supplied software (measurement interval, incident management, delayed measurement start etc.) and data that has been read can be displayed in a graph or chart, corrected using air pressure values, converted into fill levels or other units, and exported.

Specifications

- Pressure Ranges : 0…5 to 0…10 mH2O

- Total Error Band: ±0,1 %FS @ -10…40 °C

- Reading capacity: 57'000 measuring points

- Dimensions : ø 22 mm

- Special characteristics: With integrated barometer

DCX-22-ECO

-

The DCX-22-ECO data loggers are a cost-effective alternative to the highly accurate DCX-22 loggers and are only available in the cable-free «cigar» design. Thanks to their long-life battery, they can keep measuring the water level, water pressure and temperature for years (up to 10 years at a rate of one measurement per hour). The data logger can be configured using the supplied software (measurement interval, incident management, delayed measurement start etc.) and data that has been read can be displayed in a graph or chart, corrected using air pressure values, converted into fill levels or other units, and exported.

Specifications

- Pressure Ranges : 0…10 to 0…100 mH2O

- Total Error Band: ±0,25 %FS @ -10…40 °C

- Reading capacity: 114'000 measuring points

- Dimensions : ø 22 mm

- Special characteristics: With USB interface

DCX-16

-

The DCX-16 data loggers have a diameter of just 16 mm and can be used in tight spaces. Thanks to their long-life battery, they can keep measuring the water level, water pressure and temperature for years (up to 10 years at a rate of one measurement per hour). The logger can be configured using the supplied software (measurement interval, incident management, delayed measurement start etc.) and data that has been read can be displayed in a graph or chart, corrected using air pressure values, converted into fill levels or other units, and exported.

Specifications

- Pressure Ranges : 0…10 to 0…100 mH2O

- Total Error Band: ±0,1 %FS @ -10…40 °C

- Reading capacity: 57'000 measuring points

- Dimensions : ø 16 mm

- Special characteristics: Slender design

DCX-25PVDF

-

The DCX-25PVDF data loggers have been specially designed for use in aggressive liquids such as brackish water and sewage. The housing is made of polyvinylidene fluoride and the installed pressure transducer is available in Hastelloy C-276 or titanium 6AL-4V. Thanks to their long-life battery, they can keep measuring the water level, water pressure and temperature for years (up to 10 years at a rate of one measurement per hour). The logger can be configured using the supplied software (measurement interval, incident management, delayed measurement start etc.) and data that has been read can be displayed in a graph or chart, corrected using air pressure values, converted into fill levels or other units, and exported.

Specifications

- Pressure Ranges : 0…10 to 0…100 mH2O

- Total Error Band: ±0,1 %FS @ -10…40 °C

- Reading capacity: 57'000 measuring points

- Dimensions : ø 25 mm

- Special characteristics: Special plastic housing

DCX-38

-

The DCX-38 data loggers are designed for water level measurements with a high resolution in the mbar range. They can detect water levels with a total error band of just 1 mm (measuring range 0,5 m water column, compensated temperature range -10...40 °C). Thanks to their long-life battery, they can keep measuring the water level, water pressure and temperature for years (up to 10 years at a rate of one measurement per hour). The logger can be configured using the supplied software (measurement interval, incident management, delayed measurement start etc.) and data that has been read can be displayed in a graph or chart, converted into fill levels or other units, and exported.

Specifications

- Pressure Ranges : 0…0,5 to 0…3mH2O

- Total Error Band: ±0,2 %FS @ -10…40 °C

- Reading capacity: 57'000 measuring points

- Dimensions : ø 38 mm

- Special characteristics: Capacitive sensor

Multi-Parameter Loggers

DCX-22-CTD

-

The DCX-22-CTD data loggers measure conductivity and temperature as well as pressure, along with the depth of bodies of water. The integrated Pt1000 achieves an accuracy of ±0,1 °C, and the conductivity can be measured at ± 2,5% of the selected range (0,2 / 2 / 20 / 200 mS/cm). Thanks to their long-life battery, they can keep recording measurement results for years (up to 10 years at a rate of one measurement per hour). The logger can be configured using the supplied software (measurement interval, incident management, delayed measurement start etc.) and data that has been read can be displayed in a graph or chart, corrected using air pressure values, converted into fill levels or other units, and exported.

Specifications

- Pressure Ranges : 0…10 to 0…100 mH2O

- Total Error Band: ± 0,1%FS @ -10…40 °C

- Reading capacity: 114'000 measuring points

- Dimensions : ø 22 mm

- Special characteristics: Additional conductivity measurement

DCX-22AA-CTD

-

The DCX-22AA-CTD data loggers measure conductivity and temperature as well as pressure, along with the depth of bodies of water. They compensate for the air pressure using an additional, water-tight absolute pressure sensor with a stainless steel separating diaphragm. Unlike gauge pressure systems with a capillary tube, this system is completely resistant to moisture and can therefore be immersed. Thanks to their long-life battery, they can keep recording measurement results for years (up to 10 years at a rate of one measurement per hour). The logger can be configured using the supplied software (measurement interval, incident management, delayed measurement start etc.) and data that has been read can be displayed in a graph or chart, corrected using air pressure values, converted into fill levels or other units, and exported.

Specifications

- Pressure Ranges : 0…10 to 0…100 mH2O

- Total Error Band: ±0,1 %FS @ -10…40 °C

- Reading capacity: 114'000 measuring points

- Dimensions : ø 22 mm

- Special characteristics: Additional conductivity measurement

Pressure Loggers

LEO-Record

-

The high-accuracy LEO-Record digital manometers can record pressure and temperature autonomously for long periods thanks to their memory function. The data logger can be connected to a computer via the RS485 interface for configuration and for reading out the recorded data. The current pressure value can be displayed in a wide variety of units of pressure. Power is supplied by a high-quality 3,6 V lithium battery.

Specifications

- Pressure Ranges : -1…3 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @ 0…50 °C

- Interfaces: RS485

- Special characteristics: Measured value recording

- Display : 5-digit LCD display

- Reading capacity: 57'000 measuring points

LEO5

-

The LEO5 digital manometers combine a range of functions from other KELLER Pressure manometers in a water-tight stainless steel housing. They can detect pressure peaks with a measurement interval of 5 kHz and record all measurements. Current measured values and saved data can be read out via the USB connection. The pressure values can be shown on the extra-large display in a wide range of units of pressure, which are either pre-programmed or configured by the user.

Specifications

- Pressure Ranges : -1…1 to 0…1000 bar

- Accuracy: ±0,05 %FS

- Total Error Band: ±0,1 %FS @ 0…50 °C

- Interfaces: USB

- Special characteristics: All-rounder

- Display : 5-digit LCD display

- Reading capacity: 56'000 measuring points

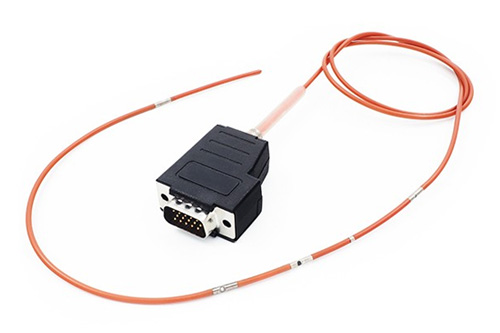

21DC-RFID

-