KROHNE

Videos

Loading the player ...

- Offer Profile

- KROHNE is a world-leading

manufacturer and supplier of solutions in industrial process

instrumentation.

KROHNE offers supporting products and services for one-stop-shopping and in industries as widespread as oil & gas, water & wastewater, chemical & petrochemical, food & beverage, power, minerals & mining and marine.

Product Portfolio

Flow measurement

-

Flowmeters, flow controllers and flow accessories

- For all industrial process applications

- From cost-effective mechanical indicators to very advanced flow instrumentation

- Maintenance and service tools, flow computers and other accessories for flow measurement

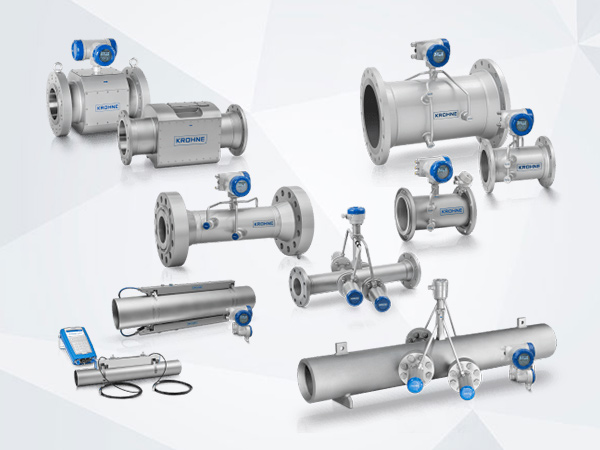

Flowmeters

-

Complete portfolio for volume flow, mass flow, density and concentration measurement

- Wide selection of measuring principles

- For liquids, gases and steam

- For basic to very advanced process applications, CT measurements, hygienic applications and Safety Instrumented Systems

Electromagnetic flowmeters

-

For all applications with conductive liquids

- From basic applications to demanding flow and custody transfer (CT) measurements

- Designs and liner materials for various applications - from potable water to extremely adhesive, abrasive or aggressive fluids

- Large choice of nominal sizes up to DN3000 / 120"

Coriolis mass flowmeters

-

For all process and custody transfer (CT) applications

- Mass, volume flow, density and concentration measurement of liquids and gases

- Secure wireless access via Bluetooth®, even in safety-related applications

- Maintains operation even with entrained gas of up to 100% (EGM™)

Ultrasonic flowmeters

-

For process and utility applications, energy and custody transfer (CT) measurements

- Comprehensive portfolio for gases, liquids and steam

- High temperature and cryogenic versions, variants for high pressure and higher viscosities

- Various designs: From clamp-on devices to multipath inline flowmeters

Variable area flowmeters

-

For simple and cost-effective flow measurement of gases or liquids without auxiliary power

- Glass and metal tube purgemeters for low-flow applications

- Glass and metal tube process meters up to DN150 / 6"

- Optional electronics: limit switches, analogue outputs, digital communication

- Glass and metal tube purgemeters for low-flow applications

Differential pressure flowmeters

-

For a wide range of process applications

- For volume, mass flow and density measurement of liquids, gases or steam

- With 3D linearisation of transmitter

- Wide range of primary elements and accessories

Vortex flowmeters

-

For utility applications, advanced energy management and Safety Instrumented Systems (SIS)

- Sophisticated flowmeters with integrated pressure and temperature compensation and integrated energy calculator for advanced energy measurement

- Certified for Safety Instrumented Systems (SIS)

- Cost-effective and robust devices for harsh process conditions and/or basic applications

Flow controllers

-

For flow indication of conductive and non-conductive liquids

- Electromagnetic or mechanical

- Cost-effective flow indication with or without power supply

- For various industrial applications

Electromagnetic flow controllers

-

For flow indication of conductive media

- Cost-effective flow monitoring of liquids, pastes and slurries

- Insertion-type devices with adjustable switching points

- Also for immersed applications

Mechanical flow controllers

-

For flow indication of conductive and non-conductive liquids

- Cost-effective mechanical measuring principle

- No power supply needed

- Suitable for hazardous environments

Components & auxiliary equipment for flow measurement

-

Flowmeter parts, flow computers, service tools and additional equipment

- Signal converters and flow computers

- Flow sensors

- Service tools and other accessories

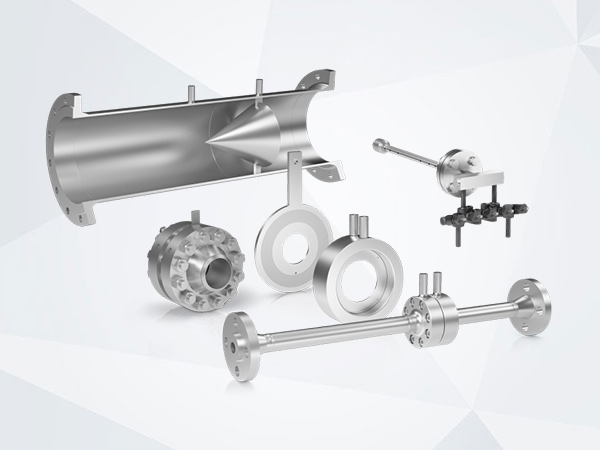

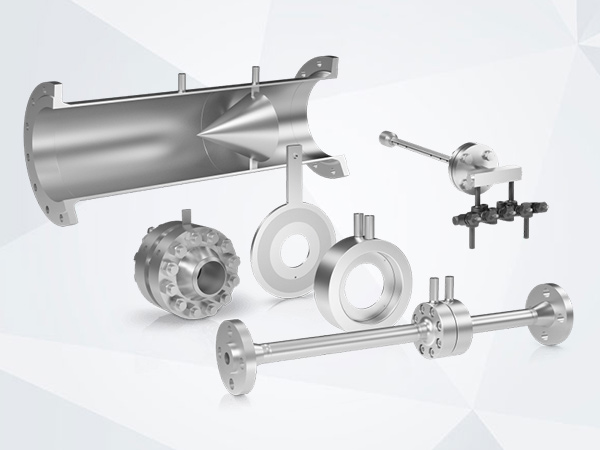

Primary flow elements

-

For flow measurement in combination with a DP flow transmitter

- Various designs of orifice plates, averaging pitot tubes and cone meters

- Standard portfolio for the most common DP flowmeter designs

- Testing acc. to ASME and PED, optional wet calibration with documentation

Flow computers

-

For custody transfer, fiscal and allocation metering

- For gas and liquid flow measurement, single or multi stream

- Easy setup and operation, e.g. with full colour graphical touch screen

- Digital, analogue, serial or Ethernet communication

Service tools

-

For on-site verification, commissioning and monitoring of field devices

- Usable on-site or from a control room

- From basic to in-depth field device verification incl. test reports

- Quick device commissioning, performance monitoring and checking of measuring values and parameters

Interface boxes

-

Signal converters

-

For flowmeters

- For combination with ultrasonic, electromagnetic, Corolis mass and Vortex flow sensors

- From basic analogue output to Profinet and other digital communication options

Flow sensors

-

For flowmeters

- For combination with ultrasonic, electromagnetic or Coriolis mass flow signal converters

- Different designs and wetted materials

Level measurement

-

Transmitters, switches, indicators and accessories for level measurement

- For continuous level and interface measurement or point level detection

- Contact or non-contact measurement of liquids, pastes, granulates, powders, solids, bulk goods etc.

- For standard or demanding applications with advanced requirements, hazardous areas and Functional Safety (SIL)

Level transmitters

-

For continuous level and interface measurement – contact and non-contact

- Various technologies: FMCW radar, TDR guided radar, ultrasonic, displacer, potentiometric, hydrostatic pressure

- For process and storage applications with liquids and solids

- Meet the requirements of various industries

Level switches

-

For point level detection and interface measurement

- Vibration forks and capacitance level switches

- For use in liquids and solids

- Suitable for extreme (pressure and temperature) conditions, hazardous and hygienic applications or safety integrity systems (SIS)

Level indicators & bypass chambers

-

For continuous level and interface measurement of liquids

- Magnetic level indicators (MLI) for a wide range of applications

- Bypass chambers (no float) for improved measuring conditions

- Can also be equipped with level transmitters (e.g. radars or guided radars)

Level accessories

-

For level transmitters and level switches

- Level signal conditioners and surge protectors

- Digital panel indicators

- On-site service and verification tools

Temperature measurement

-

Assemblies, sensors, transmitters and accessories for temperature measurement

- Resistance temperature detectors (RTD) and thermocouples (TC) for industrial process and OEM applications

- Temperature assemblies, cable probes, compact sensors and tailor-made solutions

- Head and rail mounted temperature transmitters with safe and SIL approved designs

Temperature assemblies

-

With measuring insert (RTD or TC)

- With ASME-, DIN- and NAMUR-style thermowells or customer-specific designs

- Various process connections available

- For temperature measurement across a wide range of industrial applications

Temperature sensors

-

Compact (RTD) and cable sensors (RTD, TC)

- From versions with built-in transmitters to mineral insulated cable designs

- Various process connections available

- For applications with high temperature, confined space and moving or rotating surfaces

Temperature transmitters

-

Head-mounted and rail-mounted versions

- From cost-effective analogue versions to digital, programmable variants with enhanced diagnostics

- Intrinsically safe and SIL2 approved designs

- For temperature measurement across a wide range of industrial applications

Temperature accessories

-

For temperature assemblies and transmitters

- Configuration tool for programmable temperature transmitters

- Measuring inserts (RTD or TC)

- Connections heads, thermowells, fittings

Pressure measurement

-

Process instruments for pressure and differential pressure applications

- Comprehensive portfolio: transmitters, primary elements, diaphragm seals and accessories

- Ceramic and metallic measuring cells

- For a wide range of industrial applications with liquids, gases and steam

Pressure transmitters

-

For absolute, gauge and differential pressure measurement

- From basic, ultra-compact to modular, extensible pressure transmitters

- With ceramic and metallic measuring cell

- For use in hazardous areas, hygienic environments or safety-related applications (SIL)

Diaphragm seals

-

Primary flow elements

-

For flow measurement in combination with a DP flow transmitter

- Various designs of orifice plates, averaging pitot tubes and cone meters

- Standard portfolio for the most common DP flowmeter designs

- Testing acc. to ASME and PED, optional wet calibration with documentation

Process analytics

-

Sensors, assemblies, transmitters, systems and accessories for process analysis

- Comprehensive portfolio for inline and online liquid analytical measurements

- Analytical sensors with and without integrated transmitter or complete measuring systems for all industries

- Installation equipment, signal converters and accessories to fit many requirements

Analytical sensors and measuring systems

-

For a wide range of analytical parameters

- For pH, ORP, conductivity, TSS, dissolved oxygen, free chlorine, chlorine dioxide and ozone, sludge level, turbidity or multiparameter applications

- From sensors with integrated transmitter to modular panels for liquid analytical measurements

- For any industrial requirements – from hazardous areas to hygienic environments

Analytical assemblies

-

Installation equipment for all analytical sensors

- Retractable, immersion or insertion housings

- Flow-through process adaptions and weld-in sockets

- For use in harsh environments, hazardous areas, hygienic or other applications

Analytical transmitters

-

For OPTISENS sensors

- Display of readings and alarms

- Transmitters for on-site calibration and configuration of OPTISENS sensors

- Different housing materials

Analytical accessories

-

For liquid analytical sensors

- Loop powered indicators

- Junction boxes, interface cables for offline calibration and other equipment

Control and operating units for process analytics

-

For liquid analytical sensors

- Control and monitoring functions for 4…20 mA/HART® field devices

- For on-site calibration and configuration of SMARTPAT sensors

- Different housing materials and versions for hazardous areas available

Wireless communication

-

For remote data transmission

- Industrial wireless communication of serial, digital and analogue measuring values

- Remote control stations, data loggers and wireless gateways for a wide range of applications, distances and networks

- Various communication options

KGA 42

-

GPRS data logger

- Modbus and 1 analogue or 4 digital and 2 analogue inputs

- Mobile communication via 2G, 3G

- Battery powered, in waterproof housing (IP68)

- Server-based data storage and monitoring

KBT 70

-

Bluetooth gateway for continuous data transfer

- 16 digital and 2 analogue inputs and outputs

- Based on Bluetooth 4.0: range of max. 200 m / 218.7

yd

- Mains powered and pre-wired system with fixed pair modules in rugged boxes (IP66)

- For fast and small networks

KRL 70

-

Radioline gateway for continuous data transfer

- Modbus, 4 digital and 4 analogue inputs and outputs

- Licence-free radio: range of up to 20 km / 12.4 mi (per station point-to-point)

- Mains powered and pre-wired system in waterproof boxes (IP68); with modular extension option

- For infrastructure applications with large networks (up to 250 stations)