Navigation : EXPO21XX > MATERIAL HANDLING 21XX >

H37: Profiles and Structural Elements

> R+E Automationstechnik

R+E Automationstechnik

- Offer Profile

- R+E Automation offers its

customers a comprehensive range of services in its role as system supplier.

From the mechanical and electrical construction of the systems to their assembly, control and start-up, R+E Automation covers the complete value-added chain.

Product Portfolio

Feeding Technics

Feeder

R+E BOWL FEEDER WITH TYPE FE DRIVE

R+E LINEAR FEEDER TYPE LF 1-90

R+E LINEAR FEEDER – LF 1-180, LF 2-270, LF 2-400, LF 4-670

R+E BOWL FEEDER TYPE FE / CYLINDRICAL DESIGN

R+E BOWL FEEDER TYPE FES / STEPPED DESIGN

R+E BOWL FEEDER TYPE FEK / CONICAL DESIGN

HOPPER Type VB

R+E FLOOR STANDS TYPE BSH

R+E FLOOR STANDS PROFILE CONSTRUCTION

R+E NOISE INSULATION HOOD TYPE GHS

Elevators

R+E ELEVATORS

- R+E feed elevators are used for the automatic

recharging of bowl feeders and centrifugal feed systems.

A variety of sizes are manufactured dependent

on the charge volume and container size required.

R+E STEP ELEVATOR TYPE SHF-T

- The compact R+E step elevator is manufactured

in bench design and provided with a feed section.

The feed products are sorted on a vibration rail.

R+E STEP ELEVATOR TYPE SHF-B

- Designed with automatic recharging conveyor belt.

R+E STEP ELEVATOR TYPE SHF-B

- This R+E step elevator is an autonomous floor-standing

feed system designed with multitrack step feed plates.

Control-Units

Frequency control

unit MFS 168-

Operating voltage

115/240 VAC/± 10% Operating- frequency 50 / 60 Hz

Vibration- frequency 30 – 140 Hz

Level control YES Output voltage 0-100V / 0-205V Output current 6 A max. Protection class IP54 Dimensions 205 x 93 x 191mm

R+E Control unit

RS6 RS6/539-559Operating voltage

110/240 VAC/± 10% Operating- frequency 50 / 60 Hz

Vibration- frequency 25 / 50 Hz

30 / 60 HzLevel control YES Output voltage

20-100V / 40-210V Output current 0,1 – 6 A max. Protection class IP54 Dimensions 205 x 93 x 80mm

R+E Control Unit Smart

Operating voltage

110/240 VAC/± 10% Operating- frequency 50 / 60 Hz

Vibration- frequency 25 / 50 Hz

30 / 60 HzLevel control NO Output voltage

20-100V / 40-210V Output current 0,1 – 6 A max. Protection class IP54 Dimensions 175 x 80 x 80mm

R+E Control unit

board versionOperating voltage

110/240 VAC/± 10% Operating- frequency 50 / 60 Hz

Vibration- frequency 25 / 50 Hz

30 / 60 HzLevel control YES Output voltage

20-100V / 40-210V Output current 0,1 – 6 A max. Protection class IP 00 Dimensions

125 x 112 x 110mm

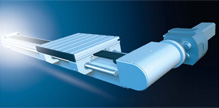

Purpose Feed System

R+E SPECIAL-PURPOSE FEED SYSTEM WITH ROLLER CONVEYOR AND ELEVATOR

- The feed products are raised by an R+E feed elevator and

conveyed over a feed rail to the R+E roller conveyor.

Automatic sort and orientation rollers ensure the correct orientation of the parts in the roller conveyor.

At the end of the feed system, the parts are conveyed over a linking rail to the downstream assembly and manufacturing process.

Centrifugal Feeder

R+E HIGH-PERFORMANCE CENTRIFUGAL FEEDER

- Centrifugal feed systems are used to achieve very high

feed capacities.

Dependent on the sorting system used and the feed product, capacities of up to 1,000 pcs/min are attainable..

Engineering

R+E COMPACT FEED SYSTEMS

- R+E bowl feeders

automatically sort, feed and transfer single parts over a vibrating rail. At

the end of the rail is a separator station that separates a single part.

The separated part is picked and placed by a handling unit or a robot. Bowl feeders are fitted with a fill level sensor and are automatically replenished by an R+E hopper.

The complete feed, separator and charging station is mounted on a common base plate and forms a compact unit.

The machine is available to customer specifications without controller or, as an alternative, with a complete station control system.

Specialmachines

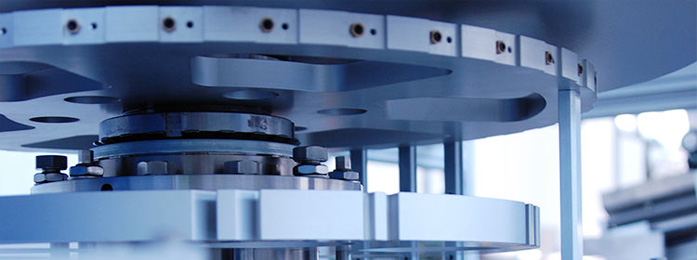

Rotary Indexing Assembly Machines

- The R+E Unimat, i.e. a modular assembly machine, is

manufactured in a compact design and is universally applicable for many

products. The assembly machine is producible with 8, 12, 16, 20 or 24

stations.

Vertical and horizontal movements are cam-controlled with fully mechanical operations. Through the use of frequency-controlled drive motors, the speeds of the rotary indexing table and the cam-controlled handling units are symmetrical and their control is infinitely variable.

MACHINE FRAME

- The R+E machine frame is made in a sturdy welded steel construction that provides a stable base for mounting the assembly machine later.

BASE MACHINE WITH LIFTING PLATE

- The rotary indexing table is mounted under the assembly

platen. It is driven by an AC motor which is also driven by a cam mechanism

comprising 3 cams and levers.

Above the machine platen is a cam-controlled lifting plate, a fixed assembly plate and an installation plate.

BASE MACHINE WITH HANDLING UNITS

- The handling units mounted on the fixed assembly plate are driven in the horizontal and vertical planes by the cam-controlled drive motor. A second higher level lifting plate regulates the necessary control movements.

R+E UNIMAT

- Fully mounted R+E Unimat assembly machine, equipped with cam-controlled handling units, main controller, operating panel and safety devices. This is the base machine used for further expansions to obtain complex assembly machines.

Canula-Bounding Machines

- The qualification requirements to cannulas have reached a

maximum level due to the great number of different requirements, e.g.

administration of vaccinations and medication or taking blood samples.

R+E cannula bonding machines of series MA-KK are the latest generation of high-performancesystems. All quality requirements and tests of our customers have been considered and can be selected as modules.

R+E assembly machines are used around the world.

The R+E cannula bonding machines of series MA-KK are available in the following versions:- 1-track – up to 3000 production rate/h

- 2-track – up to 6000 production rate/h

- 4-track – up to 12000 production rate/h

- 6-track – up to 18000 production rate/h

R+E ASSEMBLY MACHINE FOR GLASS SYRINGES

- This adhesive and assembly machine automatically feeds and positions glass barrels, inserts and then glues the canulas. This is followed by the UV curing of the adhesive. Optional stations, such as a pull test, camera inspection of the needle tips, siliconisation of the canulas, flow tests, etc., ensure that the product is assembled correctly and tested. The assembled and tested parts are automatically placed in trays.

R+E ASSEMBLY MACHINE FOR DISPOSABLE SYRINGES WITH INTEGRATED NEEDLE

- This assembly machine also inserts canulas in barrels,

glues them and subjects them to a UV curing process. After siliconising the

needles and passing through integrated test stations, a protector is fed

automatically and placed on the final product.

R+E ASSEMBLY MACHINE FOR DISTRIBUTOR SOCKETS

- Can bottoms are fed automatically on this assembly machine and inserted in the machine. Later stations include the automatic feed and insertion of a catch, placement of a cover and the automatic labelling of the appliances.The assembly machine is equipped for changes to 3 different product sizes.

R+E ASSEMBLY MACHINE FOR FUSES

- The fuse body is automatically fed and presented. This is followed by the automatic feed and placement of the two end caps. Finally there is an electrical test and selection in OK and NOK parts.

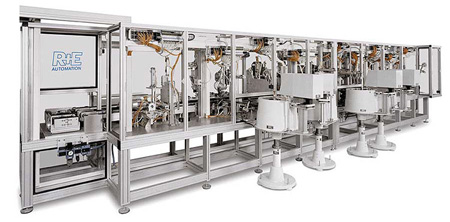

Track Assembly Machines

R+E 2-Track Assembly Machine for Terminal Strips

- Fully automatic assembly of terminal strips.

The block, the screws clamps and the screws are fed automatically by bowl feeders and assembled in a fully automated process. The screw depth is tested by a separate check station. The assembly is then ejected selectively depending on the check result.

R+E 4-Track High-Performance Assembly Machine for Terminal Strips

- In this high-performance assembly machine, the terminal blocks are fed by bowl feeders. The screws clamps are fed 4 at a time. The screws are fed simultaneously 8 at a time and torqued in. Check stations ensure a functional work process.

High Performance Assembly Machines

R+E High-Performance Assembly Machine For Screw Caps

- The assembly machine functions with continuously

operating assembly stations.

The caps and inserts are fed automatically from bowl feeders and then assembled and tested in a continuous process. Output dependent on part size approx. 300-700 pcs/min.

R+E High-Performance Assembly Machine for Special Syrings with Canulas

- The syringe barrels are fed by a special high-performance

feed system comprising elevator and

roller conveyor, and are routed to the Kontinumat® machine.

The canulas are fed by a high-performance bowl feeder and also routed to the assembly machine.

The parts are assembled, tested and discharged in the continuous assembly process.

Assembly Transfer Lines

R+E ASSEMBLY TRANSFER LINE FOR SOLENOIDS

- R+E assembly lines are designed as modular with flexible

cells so that, as required, a change can be made to stations or the entire

machine can be extended. One side of the machine is the operating side. The

automatic feed and assembly stations are mounted on the rear of the machine.

The workpieces are transferred by a double-belt system and automatically fixed in the workstations. Integrated checks ensure an optimum work process. At the end of the assembly line, the assembled solenoids are subjected to intensive inspections in mechanical and electrical tests.

Engineering

R+E ENGINEERING – YOUR SUCCESS IS OUR CHALLENGE

- A final design starts with the first sketches and

gradually matures from using the latest CAD programs. Our standard software

tools include ProEngineer, Inventor and AutoCad.

Not only that, we use risk analysis methods such as FMEA as well as project management tools. Through constant training, we prepare our staff for the increased requirements in the special-purpose mechanical engineering and control technology.

For electrical engineering design, we employ E-Plan and EL-Time taking into account the latest changes in standards. One of the main decisive advantages of R+E is our profound expertise in the field of feed technology.

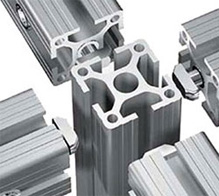

Aluminium Profil System

- R+E

is the profile partner and dispatch warehouse for MayTec Systemtechnik in

North Wuerttemberg.

To meet the high expectations of our customers and guarantee fast delivery,we manage a large warehouse of aluminium profiles and accessories. Profile System

Handling

- The MayTec profile system is easy to process and quick to

assemble.

Its flexible, modular construction means it can be easily modified and is reusable at any time.An experienced team will support you in implementing the MayTec system, tailored to your individual requirements.The design depends on the required dimensions, loading capacity and stability.

Applications

The Profile System

The Tube-Clambing System

The Clean-Room System

The Linear System

The Conveyor System

Protective Barriers

The Telescopic System

Engineering

- The MayTec service is as versatile as the MayTec profile system:

-

- Customer consultation and support

- Project engineering for innovation solutions to meet your requirements.

- Design and parts list generation using 2D and 3D design software (AutoCAD bzw. Pro/Engineer) with additional software B&W Profiles.

- Delivery of standard elements ex works

- Delivery of profiles and accessories cut to size according to parts list for customer assembly

- Delivery of pre-assembled modules

- Delivery of completely assembled units

- Assembly at your premises

- The complete range from simple frames to complete machine enclosures.

-