SMI

Videos

Loading the player ...

- Offer Profile

- Your specialist for

individual handling

Vacuum lifters, handling equipment, crane construction kit

Anybody who wants to handle materials and products today needs an expert and experienced partner.

For over 30 years, SMI has been providing handling equipment for the transportation of materials.

Product Portfolio

Vacuum lifters, handling equipment, crane construction kit

-

Our main focus is the development of solutions for product handling with vacuum technology. Electric chain hoists, KBK light crane system and slewing jibs are also parts of the SMI product range.

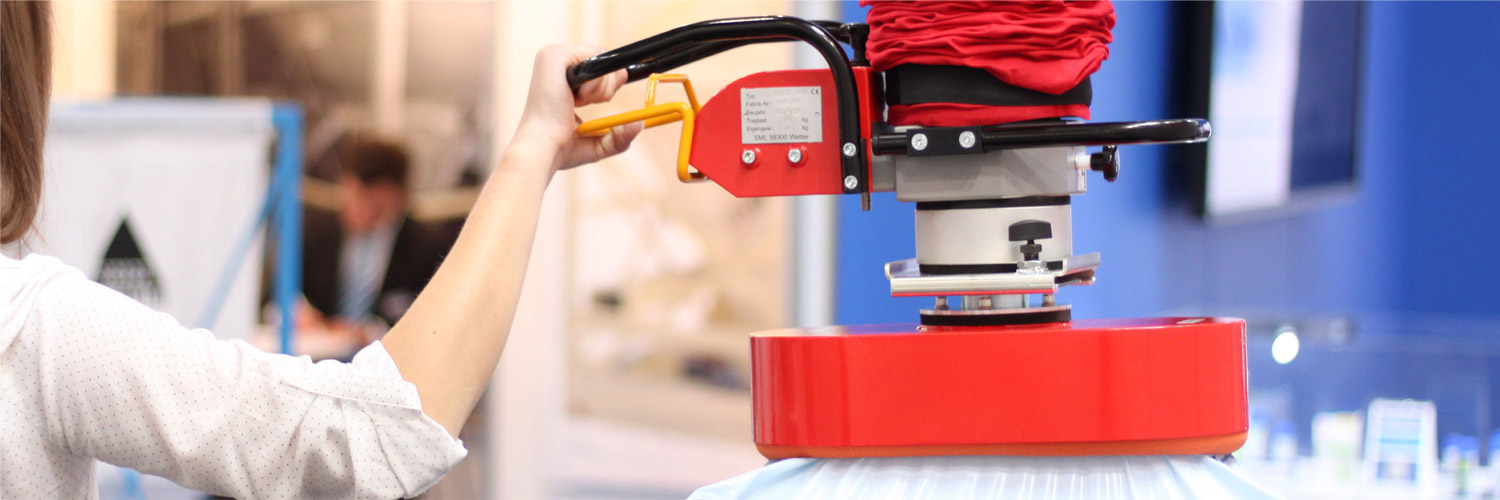

SMI uses innovative techniques to facilitate handling operations. mini smilift the small companion

- mini smilift, allows you quick and frequent movement of loads of up to 60 kg either in cartons, boxes, and bins or as individual items such as plates and machined parts. This compact unit is light and flexible with one-hand-control for pick and place applications in frequent handling operations. It can be equipped with a range of attachments for use with many types of load in production, warehouse and despatch areas. mini smilift is easily and quickly installed and can be integrated into existing installations and work flows.

Load lifting attachments and application examples

Load lifting attachment H6 for carton boxes

Adjustable stainless steel load lifting attachment for carton boxes

Mechanical load lifting attachment in stainless steel for canister

Load lifting attachment for hobbocks and buckets

Load lifting attachment for buckets and hobbocks

Compact load lifting attachment H4 for carton boxes

FDA load lifting attachment H4 for carton boxes

Special load lifting attachments

Load lifting attachment in stainless steel for bags

Load lifting attachment for coils

Load lifting attachment for plastic boxes

Load lifting attachment for hobbocks and buckets

Mechanical internal gripper for bearings

Tilting device 90° for e.g. carton boxes

Control handles for optimal handling

One hand push control

Flexible prolonged handle

Extended control handle

eco smilift the universal companion

-

smilift equipment is utilised for simple and quick product handling. The gripping and lifting of the loads is implemented by means of vacuum in a work process where only the lowest amount of steering effort is required. Whether dealing with boxes, sacks, barrels, slabs or other components, the smilift is the right solution. The equipment can also be supplied in a stainless steel design or for utilisation in explosive areas.

• 30 to 220 kg

• Compact and safe

• Suitable for most handling tasks

• In seven versions

• Standard and special load lifting attachments attachable Load lifting attachments and application examples

Load lifting attachment H4 for carton boxes

Stainless steel load lifting attachment for drums

Load lifting attachment for drums

FDA load lifting attachment H4 for e.g. carton boxes

Adjustable load lifting attachment for carton boxes

Tilting device 90°

Stainless steel load lifting attachment for bags

Control handles for optimal handling

Standard control handle

Flexible prolonged handle

flexi smilift the variable companion

-

smilift equipment is utilised for simple and quick product handling. The gripping and lifting of the loads is implemented by means of vacuum in a work process where only the lowest amount of steering effort is required. Whether dealing with boxes, sacks, barrels, slabs or other components, the smilift is the right solution. The equipment can also be supplied in a stainless steel design or for utilisation in explosive areas.

• 30 to 220 kg

• For large lifting heights up to 2.700 mm

• With prolonged and modify control handle for economic operation

• Twin vacuum lifter for heavy loads

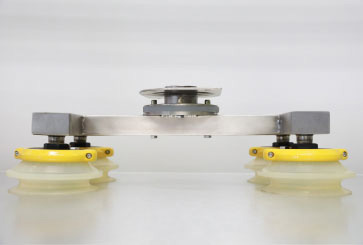

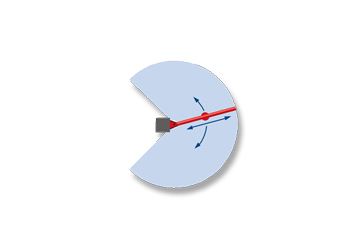

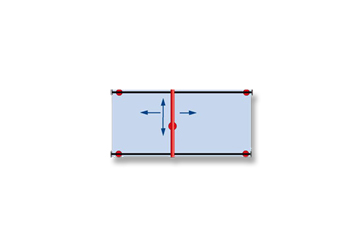

• Product-specific constructions smigrip vacuum spreader

-

Vacuum pressure makes heavy things light: Heavy weights and bulky shapes become easy to handle thanks to the vacuum technology. Steel, concrete, glass and wooden sheets, containers and barrels, pipes and profiles with weights of up to many tonnes can be transported. smigrip load spreaders assume and hold the load, cranes and hoists take over the corridor-less transport. Two models have been designed for the various requirements of the loads that are to be moved:

smigrip - robust and strong

• Standard design for loads up to 4 tonnes

• customer-specific special versions for heavy loads

• Various constructions for compact and for large surface/ volume loads

mini smigrip - compact and light

• Up to 500 kg

• Compact and light construction

• Vacuum generation via compressed air supply in accordance with the ejector principle

Vacuum spreader 01 for stable products and drums

Special vacuum load spreader for concrete blocks in shipment containers

Special vacuum load spreader for concrete blocks in shipment containers

Special vacuum load spreader for concrete blocks in shipment containers

Special vacuum load spreader for concrete blocks in shipment containers

Special vacuum load spreader for concrete blocks in shipment containers

Vacuum spreader with tilting device for vehicle bodies

Special vacuum spreader for lifting and swiveling of truck cabins

Vacuum spreader with 8 suction cups for sandwich panels

DC Electric chain hoists

-

SMI is the trade and installation partner of Demag Cranes and Components based in Wetter (Ruhr), Germany). In combination with our smigrip and mini vacuum load spreaders, Demag DC electric chain hoists provide you with high productivity, economy and operational safety thanks to sensitive handling. The diversity of the tried-and-tested load lifting appliances continues to allow you to ideally and flexibly adjust the chain hoists to the respective task.

We can also realize EX-area operations with a special chain hoist from another partner.

Designs:

2-stage chain hoist DC-Com

2-stage chain hoist DC-Pro with control unit DSC

2-stage Manulift DCM-Pro

Variable-speed chain hoist DCS-Pro

Variable-speed Manulift DCM-Pro

Stepless rocker switch DCRS-Pro

Load range:

80 kg to 5000 kg

Vacuum spreader 01 for stable products and drums

Special vacuum load spreader for concrete blocks in shipment containers

Special vacuum load spreader for concrete blocks in shipment containers

2-stage chain hoist DC

2-stage chain hoist DC with wall mounted slewing jib

2-stage chain hoist DC-Pro

KBK and slewing jib

-

The rail systems: different systems mobilise you. Depending upon the product and application, there are various equipment carriers and rail systems available for you. The crane construction kit and the pillar and wall mounted sweling jibs are also available in stainless steel and for ATEX area. If you need a mobile version, the pillar slewing jib crane can be made both adjustable and height adjustable for you.

We can find a solution for almost every situation.

Wall mounted slewing jib

- These cranes are mounted on to load-bearing concrete walls or hall pillars and therefore do not take up any floor space. The opportunity to also mount these cranes on to machines and plants creates a large operational diversity. Unloading 2m - 5m, movement radius of 180°

Pillar mounted slewing jib

- Mounted in a stationary manner or with adjustable base plate for mobile deployment. Various application opportunities in the hall or outdoors during the handling of goods or when feeding machines. The pillar, with its low space requirements, can be anchored using anchoring rods in the foundations or using on an existing concrete floor. Unloading 2m - 5m, working radius of up to 300°.

Modular KBK light crane system

- Flexible movement sequences can be planned with the ceiling rail systems. Variable track lengths and movable cross-girders can be implemented and enable a comprehensive transportation of loads. The low weight of the device ensures light shifting by hand.