- Offer Profile

-

WHAT IS OUR WORK AT AWITE ALL ABOUT?

Very simple: About gases and their processes. We analyze, desulfurize and automate.

No matter wheter agricultural or industrial biogas plants, biogas upgrading or grid injection, landfill gas, communal or industrial WWTPs, lab or power-to-gas applications.

There is a suitable analysis. For every process.

OUR APPLICATIONS IN THE FIELD OF BIOGAS

BIOGAS

- Do you have agricultural and/or industrial plants? Then we have something for you.

BIOGAS TREATMENT

- You turn raw gas into biomethane? Then we have something for you.

DRY FERMENTATION

- Whether continuous or discontinuous systems, fermenters or garage. We are well versed with it.

SEWAGE GAS

- You want to know how good your sewage gas is and how efficient your plant is.

LANDFILL GAS

- What happens where at your landfill?

POWER-TO-GAS

- The right control for your biological Power-To-Gas plant.

COMBUSTION PROCESSES

- Pyrolysis and syngas

LABS FACILITIES

-

PROVEN MANY TIMES, BUT STILL FAR FROM THE END OF THE POSSIBILITIES.

High-quality complete systems for continuous fermentation experiments. Stand-alone, groups or complete container solutions.

AWILAB GAS ANALYSIS

I ndividual, automated, expandable.- Gas analysis system AwiFLEX incl. laboratory automation

- Connection of up to

- 21 measuring points (drum gas meter) or

- 63 measuring points (Milligascounter)

- N2 Connection for pressure compensation

- Automatic emptying of the gas storage bags

- Valve circuit, pump control

- Remote maintenance access from external interface

- Discontinuous tests/ batch

- Gas volume below 0.7 l/h

- Monitoring of gas production

- Gas composition

- CH4, CO2, CO, O2, H2S, H2

- Individual gas measurement via

- time

- Quantity

- Laboratory tests with biogas, syngas, power-to-gas, ...

- and much more!

AWILAB DIGESTER

-

High-quality, sustainable, future-proof.

ALL-IN FOR YOUR RESEARCH.

- Stainless steel fermenter incl.

- Helix agitator

- Heating system

- Overpressure protection

- Condensate separator

- Sampling in the most homogeneous zone

- Gas Analysis System AwiFLEX

- Individual management and control

- Stainless steel fermenter incl.

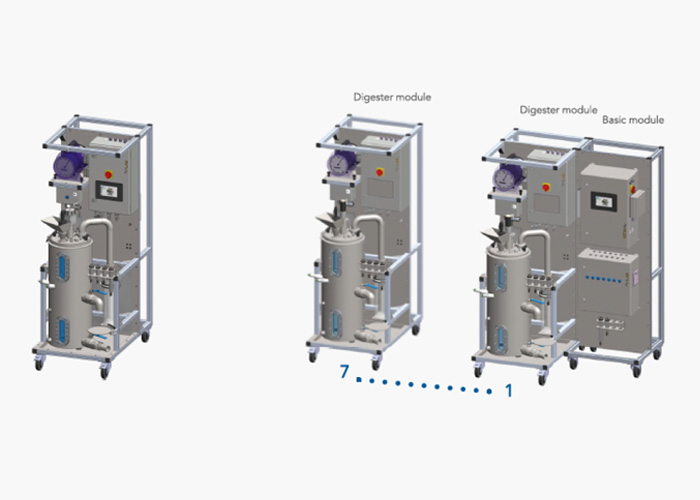

STAND ALONE OR MODULAR

- The high-quality industrial design of the entire system can be extended to up to 7 fermenter modules and complies with the standard for laboratory tests according to VDI 4630.

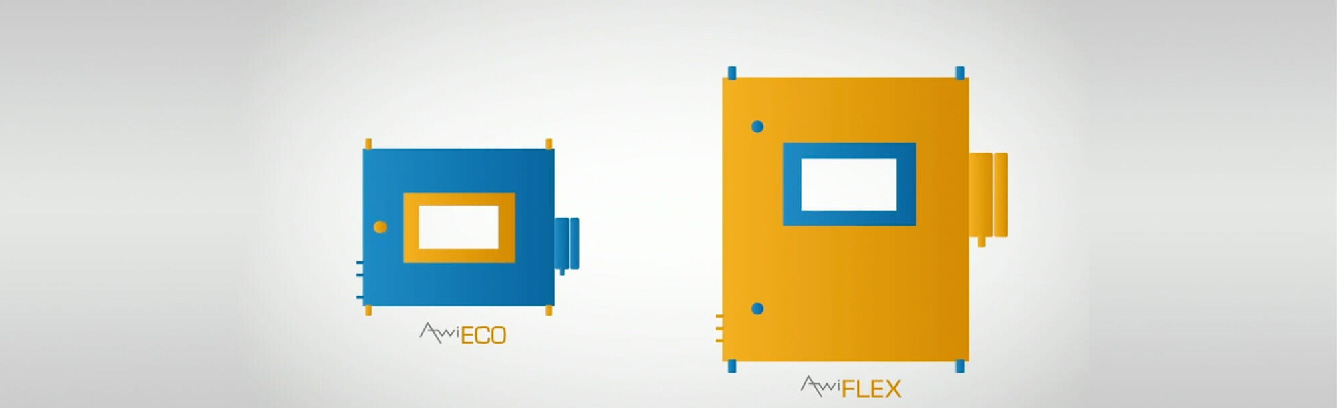

GAS ANALYSIS WITH AWIECO AND AWIFLEX

-

The comprehensive process control that is based on our gas analysis systems AwiECO and AwiFLEX ensures smooth operation and last, but not least economic efficiency of your plant on a permanent basis.

The more accurate and continuous the measurements, the more they prove to be a cost and time-saving factor.

YOU WANT MORE?

Small control tasks can be managed by AwiECO and AwiFLEX. For more complex solutions with requirements for automation we have developed AwiCONTROL.

AWIECO

-

COMPACT, COST-EFFECTIVE, STANDARDISED

- 1 measuring point (CH4, O2, H2S) or

- 2 measuring points (H2S)

Closed stainless steel cabinet

- safety | + measuring accuracy | + no contamination

Touch Panel

- simple operation | + graphic & tabular display |

- menu navigation multilingual

Upgradeabel

- flow-, temperature-, pressure- and moisture sensors

- desulfurization system (AwiDESULF)

- all established industrial interfaces

- certified for the North American market (UL/CSA)

AWIFLEX

-

X MEASURING POINTS CO(CH4, CO2, CO, O2, H2S, H2)

Maintenance-free gas cooler:

- measuring accuracy

- lifetime

- no wear out

Closed stainless steel cabinet:

- safety

- measuring accuracy

- no contamination

Touch Panel

- simple operation

- graphic & tabular display

- menu navigation multilingual

Upgradable:

- flow-, temperature-, pressure- and moisture sensors

- desulfurization system (AwiDESULF)

- all established interfaces

- certified for the North American market (UL/CSA)

AWIFLEX XL

-

X MEASURING POINTS CO(CH4, CO2, CO, O2, H2S, H2)

Maintenance-free gas cooler:

- measuring accuracy

- lifetime

- no wear out

Closed stainless steel cabinet:

- safety

- measuring accuracy

- no contamination

Touch Panel

- simple operation

- graphic & tabular display

- menu navigation multilingual

Upgradable:

- flow-, temperature-, pressure- and moisture sensors

- desulfurization system (AwiDESULF)

- all established interfaces

- certified for the North American market (UL/CSA)

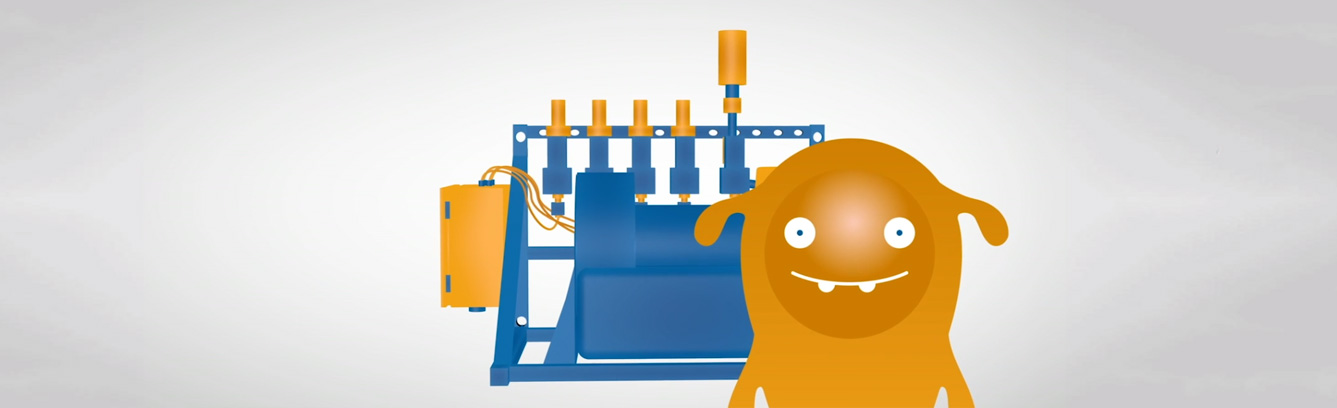

BIOLOGICAL DESULFURIZATION WITH AWIDESULF

-

BIOLOGICAL DESULFURIZATION WITH AWIDESULF

Never too much O2 in the system. For biogas plant with a capacity of 100 - 1000 m3/h.

No matter how much gas will be produced, AwiDESULF monitors continuously and regulates itself.

individual, exact, cost-effective- automatic control of air supply by a combination of PI-control and a major FuzzyLogic

- control range in automatic mode between 0 - 1 % O2 in dependence of measured H2S-concentration (shut down limit: 2,4 % O2)

- individual control of several digesters

- AwiDESULF's advantages:

- - process stability

- - minimal operational cost

- - regular measuring and O2-monitoring

- - exact control even at fluctuations of produced gas

- - remote maintenance

- certified for the North American market (UL /CSA)

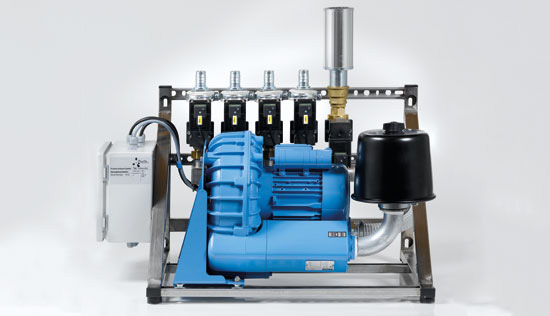

AWIDESULF 100/200

-

for biogas plants with a capacity

of 100 / 200 Nm3/h

Volume biogas/h2: up to 300 m3

Installation dimensions (WxHxD in mm): 730x580x430

Weight: ≤ 39 kg

AWIDESULF 300/500

- for biogas plants with a capacity

of 300 / 500 Nm3/h

Volume biogas/h2: up to 300 m3

Installation dimensions (WxHxD in mm): 730x580x430

Weight: ≤ 39 kg

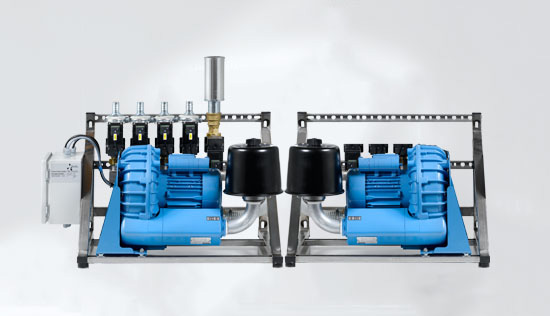

AWIDESULF 1000

- for biogas plants with a capacity

of 1000 Nm3/h

Volume biogas/h2: up to 300 m3

Installation dimensions (WxHxD in mm): 730x580x430

Weight: ≤ 39 kg

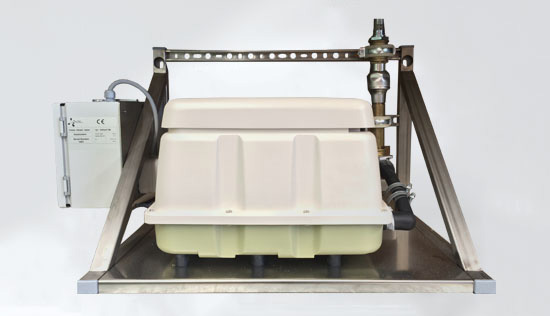

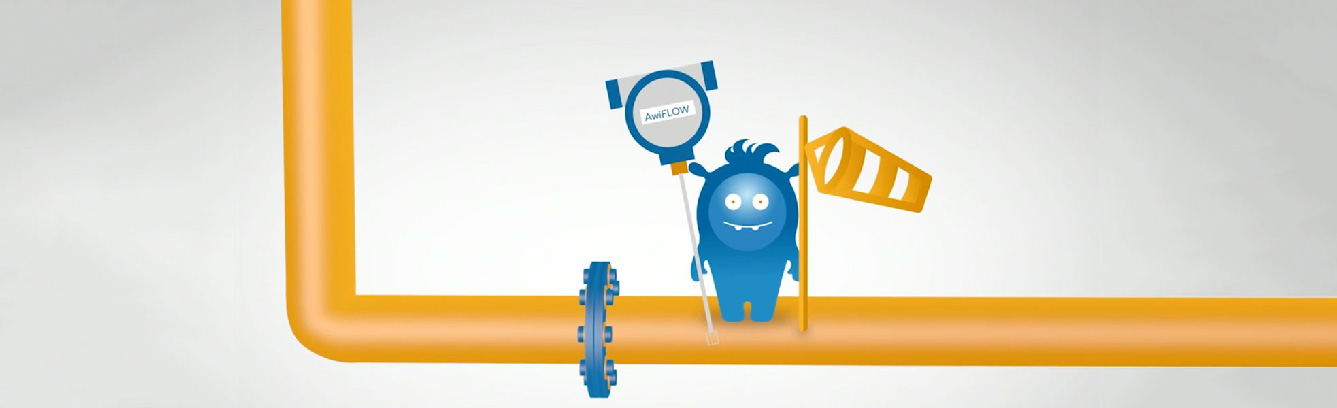

FLOW MEASUREMENT WITH AWIFLOW

AWIFLOW

-

intelligent, compact, robust

- determination of water content, standard flow and energy flow (if applicable)

- simple installation in pipe sizes (nominal widths) from DN 50 to DN 350

- cleaning and replacement of the sensor without loss of gas

- high resistance – even with humid gas containing hydrogen sulfide

- increase of the measuring accuracy through calibration with real gas

- compensation of fluctuating gas composition in conjunction with AwiFLEX & AwiECO

Services

-

SEAMLESS SUPPORT WITH AWIPLUS.

PERSONALLY ON SITE AND EVERYTHING ON BOARD

Calibration gases, spare parts and good humour are included as standard.

AWIREMOTE - PLUG IN, ALWAYS ONLINE

Whether you as the operator, we as the service, whether on site, in the office or on the road - always online.ALWAYS THERE FOR YOU:

Guaranteed professional support by our trained service staff. Whether by phone, remotely or on site.

- Gas analysis maintenance

- Scheduling

- Response times

- Spare parts & shipping

- Discount system replacement

- Settlement interval

- Support (by telephone, remotely, on site)