BIG KAISER

Videos

Loading the player ...

- Offer Profile

- Founded in 1948, BIG KAISER designs, manufactures and markets premium high-precision tooling systems and solutions for the automotive, mil/aero, energy, and microtechnology industries such as medical, electronics and watch-making. The global company has facilities in Switzerland, Germany and the USA.

Product Portfolio

Tool Holders

-

Premium Dual Contact Tool Holders

The BIG-PLUS® Spindle System provides dual contact between the spindle face and the flange face of BIG-PLUS® tooling. By simply switching tool holders, you can greatly increase tool rigidity, reduce runout and add significant productivity to your machining applications. There is a significant advantage in tool life, accuracy, repeatability and cutting capability when compared to standard tool holders.

BIG CAPTO Tool Holders offer the most accurate and flexible polygon tooling system available. Achieve the highest level of precision and flexibility for your multitasking operations. BIG KAISER offers a wider range of rotating BIG CAPTO tooling than any other provider.

HSK Tool Holders are available in a variety of forms in all the popular sizes. Our accurate and flexible HSK system achieves the highest level of precision and flexibility for your machining operations. Collet Chucks

-

BIG KAISER's collet chucks have a guaranteed runout at the collet nose of less than 0.003mm (0.00004") at 4xD, and are available for all machine tool spindles in the world.

The following products are available:- MEGA Micro Chuck: Ultra slim design. Especially made for micro machining.

- MEGA New Baby Chuck: Our most successful collet chuck up to Ø20 mm.

- New Baby Chuck: Predecessor of MEGA New Baby Chucks.

- MEGA E Chuck: The collet chuck for hard machining.

- MEGA ER Grip: The ER-collet with the best runout accuracy in the world.

- What does MEGA mean?

All MEGA collet chucks have a notch-free MEGA nut that prevents vibration and reduces noises. The collet chucks are tightened by a unique MEGA wrench that has a one-way clutch system with roller bearings and a ratchet function, which is capable of safely and evenly applying force to the entire nut periphery.

MEGA New Baby Chucks

-

High Speed Collet Chucks

The world’s highest precision & multi-purpose collet chuck system is well accepted and recognized by the market for its high-speed application and its guaranteed 1 micron runout.

The MEGA Series New Baby collet chucks are precision ground and balanced for high-speed machining. All components, including the body, collet, nut and clamping wrench are specifically designed for high-speed applications.

A new size is available to hold up to Ø 25.4 mm (Ø1.000") cutting tools.- Balanced for high speed machining

- High precision collet guarantees max runout of 1 micron at the collet nose

- 2-way coolant supply

- Wide assortment of tapers and lengths

- Only produced by BIG Daishowa for strict quality control

MEGA E Chucks

-

High Speed End Mill Collet Chucks

MEGA E Chucks are designed exclusively for end milling with high concentricity and rigidity. Gripping force is an important element for end milling with a collet chuck. The long gripping length of the MEGA E Chuck collet provides a powerful gripping force. The shallower taper of the collet improves concentricity in order to achieve better surface finishes and longer cutting tool life.

The MEGA E Series collet chucks are precision ground and balanced for high speed machining. All components, including body, collet, nut and clamping wrench are specifically designed for high speed applications.- Balanced for High Speed End Milling

- 1 micron high precision collet

- High Gripping Strength and Tapered Body for High Rigidity

- Focused Coolant Delivery for Improved Surface Finish and Tool Life

MEGA Micro Chucks

-

For Micro Drills and End Mills

A slim nut and taper design prevents interference in applications with micro drills and end mills. MEGA Micro Chuck's original design of a notch free nut prevents vibration and noise and offers superior balance and concentricity. This ideal nut design not only eliminates whistling noise and coolant splattering, but also assures increased strength of the nut itself.

The clamping range has been expanded to an 8 mm capacity and a sealed nut for directed coolant delivery has been made available (6S and 8S body sizes only).- For micro drills and end mill applications

- High precision and a super slim design for the highest rigidity

- Taper type suitable for micro end milling

- Smallest diameter .394" nut prevents inference with workpieces and jigs

- Available in BIG-PLUS® (CAT/BT), HSK, BIG CAPTO and Straight Shank

- New 8S size and sealed nut

New Baby Chuck

-

High Accuracy Collet Chuck

World’s highest precision & multi-purpose collet chuck system is well accepted and recognized by the market for its guaranteed 1 micron runout.

The New Baby Chuck collet uses knowledge cultivated through years of experience to produce the world's highest precision collet program.- 1 micron High Precision Collet

- 2 Way Coolant Supply

- Wide Assortment of Tapers and Lengths

- Only Produced by BIG Daishowa for Strict Quality Control

Milling Chucks

-

BIG KAISER Milling Chucks Power Through Your Most Demanding Cuts

Our mechanical milling chucks offer the highest gripping strength for your rough milling applications. BIG KAISER dual contact spindle interfaces improve rigidity to the highest degree which, improves your part geometry. Jet Coolant features enhanced coolant delivery to your cutting tool for improved tool life.

The most successful manufacturers in the world invest in superior tooling because it is good for their bottom line. Greater precision, longer tool life and deceased downtime are just a few of the cost saving benefits of investing in premium tooling.

MEGA Double Power Chucks

-

High Speed Milling Chucks

MEGA Double Power Chucks feature a high rigidity design for heavy cutting. Flange contacting nut and simultaneous taper & flange contact assure highest rigidity.

The expanded contact diameter of the nut of the Mega Double Power Chuck to the flange provides the highest rigidity as if the chuck and nut were one solid piece. This superior rigidity assures heavier duty machining without chatter.

The MEGA Series milling chucks are precision ground and balanced for high speed machining. All components, including the body, nut, and clamping wrench are specifically designed for high speed applications.- Balanced for High-Speed Machining

- Powerful Clamping Force

- Stable Runout Accuracy

- Exceptional Rigidity

- Jet Coolant for DS Type

- Superior Sealing

MEGA Perfect Grip

-

Non-pullout Milling Chuck

High performance no-slip, anti-pullout milling chuck for use with standard Weldon flat milling cutters. MEGA Perfect Grip combines the cutting performance of heavy-duty milling chucks with security against pullout of solid side lock tool holders. High pressure and high volume, jet-through coolant is a standard feature providing an ideal solution for milling Heat Resistant Super Alloys (HRSA) such as titanium or Inconel.- 100% Security Against End Mill Slip or Pullout

- High Volume Jet Coolant

- Exceptional Rigidity

Hi-Power Milling Chucks

-

Heavy Duty Milling Chucks

The thick wall body and high gripping force of Hi-Power Milling Chucks ensure high rigidity and stable performance. Fine and narrow slits in the body make the clamping part deform properly to ensure even & strong gripping force and stable runout.- Powerful clamping for heavy cutting

- ISO tapers are now standard BIG-PLUS®

- Coolant-through

- A slim nut design available

Hi-Power Slim Milling Chucks

-

Heavy Duty Milling Chucks with a Slim Design

The slim nut design of Hi-Power Slim Milling Chucks have optimized the ratio of the body and nut to provide high gripping force with stable runout in a smaller package. The stabilizing contact between the flange and nut also provides added rigidity for heavy milling applications.

The thick wall body and high gripping force ensures high rigidity and stable performance. Fine and narrow slits in the body make the clamping part deform properly to ensure even and strong gripping force and stable runout.- High Gripping Strength with a Slim Design

- Stable Runout Accuracy

- Superior Sealing

- Exceptional Rigidity

Hi-Power Milling Chuck J Series

-

Small Diameter Milling Chuck

Hi-Power Milling Chuck J Series is a small diameter milling chuck that provides improved milling performance over traditional collet chuck designs. The stabilizing contact between the flange and nut also provides added rigidity for heavy milling applications. Jet Coolant capability for improved surface finish and excellent tool life.

The thick wall body and high gripping force ensures high rigidity and stable performance. Fine and narrow slits in the body make the clamping part deform properly to ensure even and strong gripping force and stable runout.- High Gripping Force

- Slim Nut Diameter

- Jet Through Coolant

Hydraulic Chucks

- Hydraulic Chucks are ideal tool holders for machining processes that require high accuracy such as drills, reamers, ball mills, end mills, diamond reamers and grinding tools. With a wide variety of tool diameters and projections to fit any application, they are also available for simultaneous fit systems and all other major interfaces. Hydraulic Chucks are the perfect tool holder for high precision machining in automotive, aerospace, medical, and die & mold.

Standard Type

-

Hydraulic Chucks are ideal tool holders for machining processes that require high accuracy such as drills, reamers, ball mills, end mills, diamond reamers and grinding tools.

With a wide variety of tool diameters and projections to fit any application, they are also available for simultaneous fit systems and all other major interfaces.- High precision, smooth and stable cutting

- Pre-balanced for high speed machining

- Max. 20,000 RPM

- Easy clamping/unclamping operations with just 1 wrench

- Vibration free machining at high speed

- Use only cutting tools that have a shank tolerance of h6

Jet Coolant Type

-

Jet-Through Hydraulic Chucks are ideal tool holders for finishing applications that would benefit from improved coolant delivery. The Jet coolant flows through the end of the tool holder and is angled to direct coolant to the cutting tool tip, greatly improving surface finish and tool life.

With a wide variety of tool diameters and projections to fit any application, they are also available for simultaneous fit systems and all other major interfaces.- Jet Coolant Capability

- High precision, smooth and stable cutting

- Pre-balanced for high speed machining

- Max. 35,000 RPM

- Easy clamping/unclamping operations with just 1 wrench

- Vibration free machining at high speed

- Use only cutting tools that have a shank tolerance of h6

Super Slim Type

-

Super Slim Hydraulic Chucks are ideal tool holders for precision finishing processes in confined areas with drills, reamers, ball mills, end mills, diamond reamers and grinding tools. A wide variety of clamping diameters and projections to fit nearly any application in automotive, aerospace, medical, and die & mold.

The slim design eliminates interference and is ideal for high precision 5-axis machining.- Nose diameter min. Ø 14 mm (Ø.551")

- High precision, smooth and stable cutting

- Pre-balanced for high speed machining

- Easy clamping/unclamping operations with just 1 wrench

- Vibration free machining at high speed

- Use only cutting tools that have a shank tolerance of h6

Hydraulic Chucks for Swiss Lathe

-

Hydraulic chucks for Swiss lathe use a single wrench, which makes for an easy exchange of the cutting tool on the turret. High precision cutting by Hydraulic Chuck is achieved on the Automatic Lathe.

- Single wrench enables easy cutting tool changes on the turret

- Adjusting screw cannot be used.

Hydraulic Chuck Ultra Precision Type

-

This new Hydraulic Chuck Ultra Precision Type has all features of the Hydraulic Chuck Standard Type, but with an amazing runout accuracy.

- Adjusting screw cannot be used

- Amazing runout accuracy within 1μm at 4D.

Basic Arbors

-

BIG KAISER offers basic arbors such as Shell Mills, Face Mills, Shrink Fit, and Side Lock End Mill tool holders for conventional cutting tools.

We manufacture these holders to the highest standards with the highest quality materials. This enables us to guarantee exceptional runout, without sacrificing clamping force.

Side Lock Holders ISL Type for Weldon

-

Side fuse End Mill holders use the Weldon flat standard for secure clamping of cutting tools. Dual contact tapers provide improved performance against conventional standard taper types.

- Side Lock Holders for Weldon

- Tool bore with H5 tolerance

Side Lock Holders ISL Type for Drills

- Those Side Lock Holders are especially made for Drills.

Smart Damper for Milling

-

Integrated Damping System

BIG KAISER’s Smart Damper for milling incorporates a passive damping mechanism close to the cutting edge that functions as a counter action by way of high resonance friction action. The patent-pending system’s damping capability minimizes the effects of high frequency oscillations, absorbing vibration effectively and allowing higher machining accuracy.

When it comes to vibration and tooling the buzzword you’ll often hear is “overhang,” aka length-to-diameter ratio. That’s because as the overhang grows, it more decidedly becomes the most fragile element in the machining process and increases the chance of detrimental vibration. This is an especially common issue for die and mold, aerospace, automobile and oil and gas manufacturers.

Knowing that it’s also critical to have the damping elements as close to the cut as possible, most Smart Damper offerings are modular in design, allowing for an array of standard shanks to be adapted to create “custom” tools to extend over 16 inches, maintaining damping nearer the tool and managing vibration in long-overhang setups.- Instantaneous Damping of Chatter

- 6:1 Length:Diameter Ratio

- Coolant Through Pilot Design

- Modular Construction

Shell Mill and Face Mill Holders

-

FMA, FMB, FMC, FMH, SMC Types

Shell Mill and Face Mill Holders are conventional holders for face mill and shell mill cutters offered for a variety of international cutter specifications.

Additional rigidity for improved cutting performance is made possible by BIG-PLUS® dual contact tapers.- Dual Contact Tapers

- Available for Various Cutter Specifications

- SMC and FMH for Coolant Through Applications

Shrink Fit Holders

-

Standard Type

Shrink Fit Holders offer high clamping forces, low runout, and a small nose diameter to reduce clearance issues.- Small Nose Diameter

- High Clamping Force

- Symmetrical Design

Shrink Fit Holder Slim

-

Shrink Fit Holder Slim type reduces the nose diameter even further for reduced interference with the same runout accuracy. They offer high clamping forces, low runout, and a small nose diameter to reduce clearance issues.

- Super Small Nose Diameter

- Symmetrical Design

Shrink Fit Holder Jet Through Type

-

Shrink Fit Holder Jet Through Type include angled coolant holes in the face of the holder to supply coolant directly to the cutting tool. Shrink Fit holders offer high clamping forces, low runout, and a small nose diameter to reduce clearance issues.

Jet Coolant

Small Nose Diameter

High Clamping Force

Symmetrical Design

Tapping Holders

-

The MEGA Synchro Tapping system is perfect for high performance rigid tapping on CNC machines. The system has 41 bodies, 45 tap holders, and offer ideal projection lengths for any machine. Thread quality and tool life is improved by reducing thrust loads caused by synchronization errors during rigid tapping.

Additionally, the Drill Tapper system provides high performance for manual applications and is a unique system for drilling and tapping. This quick-change holder lets you exchange taps and drills in seconds, providing two operations with one stable head.

MEGA Synchro Tapping Holder MGT6-MGT20

-

Rigid Tapping Adapter

MEGA Synchro Tapping Holder compensates for synchronization errors during rigid tapping. It improves thread quality and tool life by reducing thrust loads caused by synchronization errors up to 90%.

Super slim nuts and varied length tap holders provide optimal access to confined areas which eliminates the need for special length taps.- Improves Thread Quality and Tool Life

- Absorbs the pitch difference between the tap and spindle when using rigid tapping

- Short, middle, long & extra long tap holders are standardized

- Coolant through center capability

MEGA Synchro Tapping Holder MGT3

-

Small Rigid Tapping Holder

MEGA Synchro Tapping Holder compensates for synchronization errors during rigid tapping. It improves thread quality and tool life by reducing thrust loads caused by synchronization errors up to 90%.

The MGT3 series is designed for very small tap sizes. The MEGA Micro collet controls dynamic runout accuracy providing stable thread quality and extended tap life.- Improves Thread Quality and Tool Life

- Absorbs the pitch difference between the tap and spindle when using rigid tapping

- High Accuracy Runout Utilizing MEGA Micro Collets

MEGA Synchro Tapping Holder

-

Large Rigid Tapping Adapter

The MGT36 series is designed for large tap sizes. MEGA Synchro Tapping Holder compensates for synchronization errors during rigid tapping. It improves thread quality and tool life by reducing thrust loads caused by synchronization errors up to 90%.- Improves thread quality and tool life

- Absorbs the pitch difference between the tap and spindle when using rigid tapping

- Coolant through center capability

JIS Standard Tap Holders

-

Our tap holders are available in short, long and extra long length to meet all production requirements. The tap shank and square must be matched. Please contact us if you need assistance selecting the correct tap holder for your job.

- Improves Thread Quality and Tool Life

- Absorbs the pitch difference between the tap and spindle when using rigid tapping

- Short, middle, long & extra long tap holders are standardized

- Coolant through center capability

ISO Standard Tap Holders

-

Our tap holders are available in short, long and extra long length to meet all production requirements. The tap shank and square must be matched. Please contact us if you need assistance selecting the correct tap holder for your job.

- Improves Thread Quality and Tool Life

- Absorbs the pitch difference between the tap and spindle when using rigid tapping

- Short, middle, long & extra long tap holders are standardized

- Coolant through center capability

DIN Standard Tap Holders

-

Our tap holders are available in short, long and extra long length to meet all production requirements. The tap shank and square must be matched. Please contact us if you need assistance selecting the correct tap holder for your job.

- Improves Thread Quality and Tool Life

- Absorbs the pitch difference between the tap and spindle when using rigid tapping

- Short, middle, long & extra long tap holders are standardized

- Coolant through center capability

Tapping Holders Spare Parts

- Spare parts such as replacement nuts, Set screws, Synchro Adjusters and O-rings for your MEGA Synchro Tap Holders.

Mill-Turn Tools

- Revolutionary! The very first modular tooling system for turning applications. Modular Mill-Turn Tools for Mill/Turn Centers (MTC's) offer better efficiency, material selection, heat treatment and optimal tool lengths. The serious damage on tool holders caused by broken inserts can now be easily and economically replaced.

45° Tilt Style Mill-Turn Tools

-

Type S Basic Holder

45° Tilt Style Mill-Turn tools tilt the "B" axis 45 degrees and helps to minimize the cutting forces transmitted to the machine spindle. This force reduction increases the life of the machine spindle.

Type S Cartridges are located in the basic holder by means of a precision ground pilot and secured by two opposing radial screws with a 15º taper. With a slight offset to locating sockets, high face-to-face clamping force of the two components is generated. To maintain precise locations and orientation, an additional locating pin is included for positive transfer of cutting torque.

These are the very first modular tooling system for turning applications on MTC's (Mill-Turn Centers). A modular tooling system offers better efficiency, material selection, heat treatment and optimal tool lengths. Serious damage to tool holders caused by broken inserts can now be easily and economically replaced.- 45° approach for the highest productivity

- Secure and rigid cartridge clamping system

- Safe and easy clamping of inserts

- 15 cartridges to choose from

90° Tilt Style Mill-Turn Tools

-

Type F Basic Holder

Type F 90° Tilt Style Mill-Turn Tools use two clamping bolts that press the cartridge onto the basic holder. The torque is transmitted by an interlocking drive slot.

These are the very first modular tooling system for turning applications on MTC's (Mill-Turn Centers). A modular tooling system offers better efficiency, material selection, heat treatment and optimal tool lengths. Serious damage to tool holders caused by broken inserts can now be easily and economically replaced.- 90° approach to reduce workpiece interference

- Simple and positive cartridge clamping system

- Safe and easy clamping of inserts

- 26 cartridges to choose from

Square Tool Holder

-

Square Tool Holder adapters for MTC style machines. They allow for the use of existing lathe tool holder technology on these more complex machines.

Dual contact tapers and tight tolerance drive keys for added rigidity and insert repeatability.- 180°, 45°, and 90° Orientations

- Adjustable Coolant Nozzles

- Tight Tolerance Drive Keys for Turning

- Right and Left Hand Versions

Boring Bar Holder

-

Boring Bar Holder for MTC style machines allow for the use of existing lathe tool holder technology on these more complex machines.

Dual contact tapers and tight tolerance drive keys for added rigidity and insert repeatability.- Tight tolerance drive keys for turning

- Center, right, and left hand coolant supply

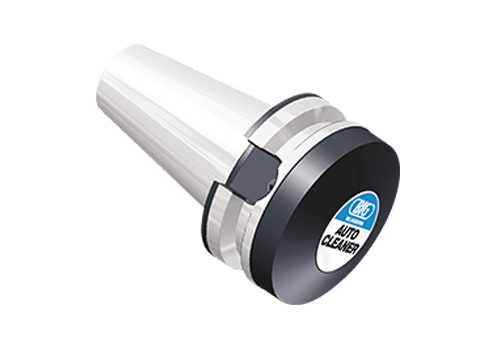

Coolant Inducers

- Hi-Jet Holders are coolant inducers that introduce coolant capabilities to machine tools without coolant-through spindles. Hi-Jet Holders minimize overheating and distortion of workpieces and allows coolant-through cutting tools to provide faster metal removal rates by flushing chips out of the holes. With reduced heat generation, tool life is greatly extended.

Hi-Jet Holder Side Lock Type

-

For Straight Shanks with a Milled Flat

Hi-Jet Holder Side Lock Type is designed for popular straight shanks with a milled flat. It introduces coolant capabilities to machine tools without coolant-through spindles.

Hi-Jet Holders minimize overheating and distortion of workpieces and allows coolant-through cutting tools to provide faster metal removal rates by flushing chips out of the holes. With reduced heat generation, tool life is greatly extended.- Introduces coolant capability

- Allows operations at faster speeds and feeds

- Non-contact seal design eliminates wear damage to body

- Compact design

- Suitable for small diameter cutters

- Automatic Tool Change w/ stop block

- Easy maintenance of worn parts

- 284 max PSI

- Water-soluble coolant only

- 360º adjustability

- High speed available (10,000 RPM for 40 tapers - 8,000 RPM for 50 tapers)

Cutting Tools

-

BIG KAISER offers a full line of high precision drills. From solid carbide, high speed steel, indexable insert drills, spade drills and micro drills. BIG KAISER drills are the superior choice for increasing production capacity and quality in all application especially extreme conditions.

Indexable end mills provide sharp cutting edges by both high radial and axial directions which helps to maintain smooth and quite end milling. BIG-PLUS® dual contact fit design allows for higher precision and rigidity in your precision applications.

Chamfering tools are offered in several different types to optimize performance for a given application. Small cutters with multiple inserts allow profile chamfering with optimal feed rates. Other cutters feature large chamfering inserts which permit I.D. chamfering over a wide range of bore diameters. Indexable Cutting Tools

- Indexable cutting tools can offer significant advantage over standard solid carbide tools. Choose from Indexable insert drills and milling cutters. Whether your centering, drilling, chamfering, back spot facing, end milling, or face milling, we offer premium cutting tools to increase your productivity. High performance insert grades and coatings are also available.

C-Centering Cutter

-

Spot drilling/chamfering tool C-CENTERING

The C-Centering Cutter is a multifunction cutter capable of both spot drilling and chamfering. The coolant hole allows cooling of the cutting edge, which reaches high temperatures during spot drilling in particular, and enables immediate chip evacuation.

During spot drilling, the insert nose radius can be easily chipped with general cutters since the center has a peripheral speed of zero. At the nose radius on the C-Centering Cutter insert forms negative land, it has high chipping resistance and the tool life is significantly extended.- Immediate chip evacuation with coolant

- Prevents chipping during spot drilling

Center Boy

-

Accurate Centering and Chamfering for Drilled Holes

Center Boy can achieve accurate centering and chamfering in a single operation. It features sharp cutting with minimum interference thanks to a slim and extended shank. The cutting tip is easily replaced to maintain high performance without need for re-grinding.- Performance maintained through replacement of cutting tip

- Long shank type available for less workpiece interference

C-Cutter

-

Optimized 45º Chamfering

Designed exclusively for chamfering, the C-Cutter inserts have high rake angle to produce clean chamfer surfaces. The large cutting surface covers a wide range of diameters and reduces tooling numbers and ATC time loss.- Offered in fixed and adjustable angle types

- Large cutting edge allows plunge cutting over a large range of diameters

- Exclusive double-screw indexable inserts

C-Cutter Boy

-

Chamfering Solution for Manual Mill/Drill Press

C-Cutter Boy is designed to simplify your chamfering operations on manual bench drilling machines. Its Carbide support pads and Carbide inserts provide long tool life. 3 cutting edges make it an economical option.- Carbide insert provides excellent chamfer surface

- Carbide guide prevents chatter, enabling easy operation

C-Cutter Mini

-

High-Performance Indexable Chamfering Tool

The C-Cutter Mini is an ultra-high feed chamfering mill with a compact design. This design reduces the cutting diameter to the lowest limit, helping to achieve ultra-high spindle speeds and feeds. The C-Cutter Mini delivers multi-functional cutting, including chamfering, back chamfering and even light face milling. The C-Cutter Mini is available in single insert and 4-insert designs.- Performs chamfering, back chamfering & light face milling

- Ultra high feed rates

- Increased spindle speeds

- Increased cutting speeds

- Reduces hand de-burring

- Small cutting diameter

- Indexable inserts with 4 cutting edges

- 4-insert design allows 45º chamfering

- 1-insert design allows 30º, 45º and 60º

R-Cutter

-

Ultra High Feed Radius Chamfer Mill

R-Cutter is an ultra-high feed radius chamfer mill capable of front and back chamfering. It has a unique insert geometry offers excellent sharpness and its high rake angle reduces cutting resistance and minimizes the generation of burrs. There are indexable cutters with up to 4 cutting edges for fast, efficient production of radius edges.- Four insert design multiplies the feed rate

- Single insert design for confined spaces

- Unique insert geometry with excellent sharpness

- For cast iron, aluminum, and all steels including stainless

- High rake angle reduces cutting resistance and minimizes the generation of burrs

BF-Cutter

-

Back Spot Facer

The BF-Cutter was exclusively designed for back spot facing of capped bolt holes, sizes M6-M16, or 1/4"-5/8. It features the world’s smallest square indexable insert, (with 4 indexes), and is ideal for all steels, (including stainless), cast iron and aluminum.

The coolant-through capability helps cool down the back side cutting area, increasing tool life – a feature not available in most other models on the market. The BF-Cutter is available for minimum facing diameters. A unique, offset design allows for easy programming – simply offset the centers between the machine spindle and the hole when entering or exiting the hole with the cutter.

Easy NC Programming

Easy programming by simply offsetting the centers between the machine spindle and hole.- Cap bolt size M6-M16

- Indexable inserts save costs

- Utilizes worlds smallest square insert

- Coolant through design increases tool life

Fullcut Mill Contact Grip

-

The Fullcut Mill Contact Grip has a threaded connection with precision-ground mating taper and face that permits easy indexing of cutter heads while maintaining excellent rigidity.

- Available in BIG-PLUS® BT, HSK, and BIG CAPTO tapers

- Four connections sizes and 7 cutter types available

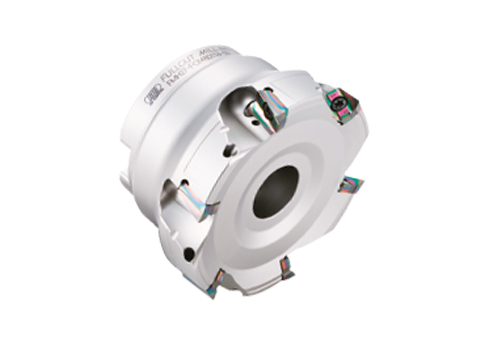

Fullcut Mill FCM Type

-

Square Shoulder & Slot Milling Cutter

Fullcut Mill FCM Type have a positive high rake cutting edge for both radial and axial directions, achieves smooth and quiet end milling. Fullcut Mills have a sharp cutting edge by both high radial and axial rake angles and positive rake angle offering high toughness in a highly rigid integral body. Indexable insert end mills with both excellent sharpness and toughness, achieving the performance of solid end mills.- Strong cutting edge

- Secure insert clamping

- Highly rigid integral body outperforms solid end mills

- Dual face and taper contact

- Highly efficient end mills with low cutting resistance

Fullcut Mill FCR Type

-

Square-Shoulder, Helical, and Ramping Milling Cutter

Fullcut Mill FCR Type is an indexable insert end mill offering supreme cutting performance for your most demanding milling applications. FCR offers lower cutting resistance than any other competitors. A rigid integral body is optimal for all machining centers. The positive high rake sharp cutting edge for both radial and axial directions achieves smooth and quiet end milling.

Designed for shoulder and slot milling, ramping, helical milling, and plunge milling.- High rake angle and ground cutting edges sharply reduce cutting resistance

- Strong cutting edge reduces edge chipping

- Lower cutting resistance than any other competitors

- Achieves 5 times greater DOC than other high rake cutters

- Higher rigidity with integral body and dual contact system

Fullcut Mill Arbor Type

-

Fullcut Mills have a sharp cutting edge by both high radial and axial rake angles and positive rake angle offering high toughness in a highly rigid integral body. The Fullcut Mill Arbor type corresponds to form FMH of the new standard face milling adaptor. Recommended use with our dual contact shell mill holders or our Smart Damper.

- Achieves excellent squareness

- Leaves a fine surface finish

Speed Finisher

-

The Speed Finisher allows for ultra-fast cutting height adjustment within 1μm of each other, offering mirror-like finishes through maximum speeds up to 20,000 RPM. After clamping the insert, the finely-pitched lifting screw lifts the insert directly by revolving the lifting nut from the side.

- High Speed Cutter for Aluminum and Cast Iron

- Quick Adjustment of Cutting Edge Height

- Light Weight & High Rigidity

- Secure Coolant Supply to the Cutting Edges

Surface Mill

-

The surface mill is a 45° approach face milling cutter for superior surface finishes. This mill was developed based on the C-Cutter Mini chamfering tool platform, and therefore utilizes the same inserts.

Our tests concluded the surface mill outperformed other manufacturers similar mills in surface roughness measurements.- Utilizes 4 indexable inserts mounted at 45°

- Insert grades available for most materials

- Coolant ports direct to the inserts

- Mounts to Ø1.000" pilot hole shell mill arbors

- 80mm cutter diameter

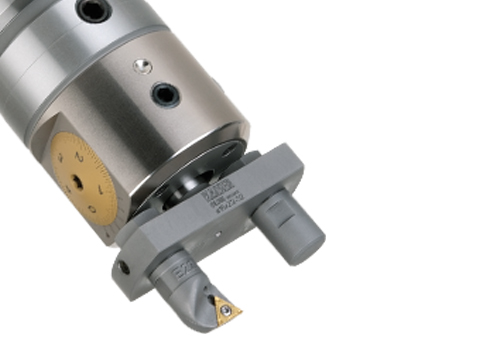

Boring Tools

-

The precision and ruggedness of BIG KAISER modular boring tools deliver measurable performance advantages—significantly reducing costs and cycle times. The modular CK system is the best solution for drilling, rough boring, finish boring, milling and tapping. Modular boring tools provide flexibility to assemble the perfect setup for almost any application.

Through systematic development combined with countless practical tests, the well known CKB modular system can be easily upgraded to cope with the requirements of today's high performance tools. Modular Components

Modular Components

-

Our modular components are based on a cylindrical connection with radial locking screw. The BIG KAISER CK modular precision tool system has continuously been improved over the years, and has adapted to customer’s needs and the increases in machine tool performance. Compatibility to existing tools has always been a requirement for newer designs. This means that all BIG KAISER connections are almost 100% compatible, and all components are available from stock.

The World's Most Versatile Tooling System

BIG KAISER's modular CK system is fully compatible with all machine tool interfaces and allows the possibility to create tool assemblies specifically designed to satisfy your demands. Optional features such as anti-vibration, balance compensation, digital readout, and aluminum construction are all available from stock. The versatility of BIG KAISER tools leaves nothing to be desired.

Rough Boring Heads

-

BIG KAISER specializes in high-precision modular tooling systems, and goes to great lengths to ensure superior performance and repeatability. The twin cutter boring program is a great example of superior performance and is designed for heavy duty rough boring and semifinishing operations.

Our rough boring heads are designed for ultimate performance and versatility. Take the Series 319 SW twin cutter boring heads for example. A unique design feature allows the 319 to perform balanced or stepped cutting without additional accessories or adjustments simply by switching the mounting locations of the insert holders that have varied heights. This gives our system one more distinguishing feature – less components than our competition when switching between different roughing methods.

MW Rough Boring Heads

-

Roughing in the small diameter range

MW Rough Boring Heads are straight shank indexable rough boring tools for small diameters based on the BIG KAISER 319 SW series. They are an ideal solution for semi-finish or finish boring operations of workpieces with die cast holes as they allow for extremely fast roughing of small holes.- Spiral groove to improve chip evacuation

- Cylindrical Shank

- Die steel insert holders

- Strong clamping through mating serrations on tool body and insert holders

- Coolant through options for blind hole and through hole situations

- Commonly accepted Ø 20 mm shank is used (should be held in a milling chuck)

Rough Boring Heads TWN 315

-

Roughing beyond limits

Rough Boring Heads TWN 315 twin cutter boring heads are designed for heavy duty rough boring and semi-finishing operations. Their compact, sturdy design and positive geometry allow almost chatter-free operation even in interrupted cuts and high cutting speeds.

Twin cutter boring heads can outperform single cutter finishing heads by a factor of up to 4 times. Large stock allowances and high feed rates permit high production while assuring optimum bore roundness and location, two important quality features for today's tighter control of part geometry. In many cases, these tools can eliminate the need for semi-finishing cuts due to the superb balance of cutting forces, even under the most severe casting core shift.

Rough Boring Heads TWN 315 series tools use ISO standard inserts with positive cutting geometry for reduced cutting forces. The top clamp free mounting of the inserts and wide open chip spaces between the insert holders allows perfect chip formation and evacuation. Different grades and geometry's of carbide and silicon nitride inserts are available to optimize all application criteria.- Highest stability and length accuracy due to a special, ground profile connection on both ends between tool body and insert holder

- Additional insert holder for each head size for extended boring range and more chip space when blind hole roughing

- Through-tool coolant supply, with adjustable coolant nozzles for sizes 53 and larger

- ISO standard inserts in various shapes and different geometry for all work piece materials

- Simple handling and compact design

Rough Boring Heads SW 319

-

Perfect Roughing

Series SW 319 twin cutter rough boring heads are designed for heavy duty rough boring and semi-finishing operations. The short and compact design of the components combined with a positive and friction locked connection between the tool body and insert holders provide maximum rigidity and highest cutting performance.

This twin cutter series has a unique design feature allowing different roughing methods without the need to change components or use mechanical systems to adjust insert height. Simply reverse the insert holders to switch between balanced and stepped cutting!

Ground serrations on the mating surfaces of both tool body and insert holder permit a rigid connection and an accurate tool length. A diameter scale on the insert holders allows diameter adjustment without a presetter. Tool body and insert holders are completely protected against corrosion by a high quality coating.

Different accessories also permit chamfering, back boring and face grooving.- Stock removal of the final diameter of up to 40%

- Repeatable length accuracy due to ground serrations on the mating surfaces of both tool body and insert holder

- Insert holders for extended boring range as well as back boring

- Coated tool body and insert holder

Series 319 SW Aluminum Rough Boring Heads

-

Perfect Roughing

Series 319 SW Aluminum Rough Boring Heads provide the maximum rigidity and cutting performance. This is achieved by the short and compact design of it's components combined with a positive and friction locked connection between the tool body and insert holders.

These boring heads are an ideal lightweight solution for rough boring on 30 and 40 taper size machines with limited tool weight for automatic tool change.- Stock removal of the final diameter of up to 40%

- Repeatable length accuracy due to ground serrations on the mating surfaces of both tool body and insert holder

- Insert holders for extended boring range as well as back boring

- Coated tool body and insert holder

Series 318 Large Diameter Boring System

-

Super light system provides highest precision and performance

The Series 318 Large Diameter Boring System is designed for heavy roughing of bores—and a special adapter can extend the system even further. The lightweight and secure configuration makes it ideally suited for higher speed operations-up to 6600 SFM. For use on production machines such as boring mills and machining centers with spindle taper sizes of 40 and larger.

The system is based on aluminum extension slides of different lengths, which support a variety of aluminum and steel components for roughing and finishing tool assemblies. The mounting components are pinned to fit onto specific locations on the slides, and secured with steel bolts. The precise positioning of the components on the slide along with incremental adjustment scales for insert holders permit diameter and length setting without a tool presetter.- Versatile system for various applications such as roughing, finishing, pin turning and face grooving

- Coolant supply through all components to the cutting edge

- Absolutely safe mounting of the components on the extension slide for highest safety in operation

- Flanges with CKN connection for highest torque transmission with lightweight tools

- High strength and hard coated aluminum, and nickel coated steel components for scratch resistant and rust protected surfaces

- Accurate balancing without balancing machine by means of two-piece counter weight with slide and scale

Series 317 Large Diameter Boring System

-

Highly precise, rigid and safe to operate

The Series 317 Large Diameter Boring System is designed for heavy roughing of bores. The compact rugged configuration makes it ideally suited for use on production machines such as boring mills and machining centers with spindle taper sizes of 40 and larger.

The modular components such as flange, extension slide, tool holder and boring head, can easily be assembled to single cutter, twin cutter and pin turning tools.

Compatibility

New components with safety screws can be mounted on existing extension slides without any restrictions whereas the safety screws must be removed. Existing components without safety screws can as well be mounted without any restrictions on the new extension slides.

Modification

On request, safety screw modifications can be made to existing precision boring heads and extension slides to prevent tool breakage from accidentally high spindle speeds.

Please consult with our engineering department for more information.- Twin cutter boring tools for various roughing methods, (RSS = symmetrical roughing, DVS = double offset roughing and VPS = full profile roughing)

- Precision boring tools with high adjustment precision, (for forward and backward boring)

- Highest possible operational safety with additional safety screws

Fine Boring Heads

- BIG KAISER offers the most complete line for tooling in a modular boring tool system. Our fine boring heads are great high precision finishing options for small, medium, and large diameter applications. Digital, balanced or classic analog boring heads built of steel or aluminum are available for the highest performance. Additionally, a wide selection of reduction bushings, carbide or hardened steel boring bars, and replaceable insert holders assure optimum tool selection for nearly all bore diameters and depths.

EW 15-18 Boring Heads

-

For precise finishing operations of small diameter bores with high spindle speeds

These boring heads are designed to be used in combination with the steel or carbide-boring bars out of the accessory program, Series 112. In conjunction with the long carbide bar, the tool is well suited for vibration-free finishing operations in bores with unfavorable Ø/L-ratios. There are various integral and modular options for clamping these boring bars. Please see the chapter on tool holders.- Highly accurate and purely radial cutting edge adjustment

- Through tool coolant to the cutting edge

EWB 2-50 Balanceable Boring Heads

-

EWB 2-50 balanceable boring heads maximize cutting speeds and feeds on small diameter bores due to an integrated counterweight, which allows for precision balancing of the tool assembly. By using charts that are applied with these boring heads, the graduated scale ring can be rotated to the correct setting to offset the unbalance of the various boring bar/inset holder combinations possible with this versatile system. Significant improvements to bore quality, surface finish, and tool life are all the result of balanced tooling.

To balance the whole tool combination there are pre-balanced shanks and components available. Even at maximum speeds, balanced tools guarantee vibration-free boring, resulting in increased productivity and high precision.- Short and compact boring head with an extremely rigid construction

- Ground and play-free fitted micrometer spindle for a very precise and direct adjustment of the tool carrier

- Coated tool body for complete protection against corrosion

- Variable length adjustment of the tool holder ensures optimized boring depth setting

- Integrated counterbalance mechanism allows fine balancing for multiple assembly configurations by rotating the scale ring according to adjustment tables included with the boring head.

EWB 32-105 Boring Heads

-

Self-balance over the entire adjustment range

Autobalance boring heads, Series 310 EWB, maintain perfect balance throughout the work range due to the integrated counter-balance mechanism. Even at maximum speeds, balanced tools guarantee vibration-free boring, resulting in increased productivity and high precision.

Self-balancing mechanism

A counterweight built into the boring head compensates for the imbalance caused by the movement of the tool carrier.- Absolutely free from any movement with combined clamping of insert holder and tool carrier

- High quality coated tool body for complete protection from corrosion

- Through tool coolant supply to the cutting edge

- For cutting speeds up to 2'000 m/min

EWB AL 100-203 Balanced Boring Heads

-

Highly precise, ultra lightweight with self-balancing over the entire adjustment range

EWB AL balanced boring heads are made of high strength aluminum with hard coating. Together with reductions and extensions made in the same way, the weight for long and large diameter tool combinations is reduced by more than 50%. This means that weight problems during ATC and handling are eliminated to a great extent.- Ultra lightweight

- For forward and back boring applications

- Cutting speed up to 2,000 m/min

- Automatic precision balance over the entire work range

EWB-UP 25-100 Boring Heads

-

Peak performance and precision uniquely combined

The revolutionary new EWB UP series sets higher standards for boring heads concerning adjustment accuracy and balance quality. Diameter adjustments in the sub-micron range via a high-precision adjustment device and finely-adjustable balance compensation are requirements for tight tolerance bores with maximum rpm‘s.- Dial adjustments of .00005"/Ø (.001m/Ø) without need for vernier scale

- Absolutely free from any movement with combined clamping of insert holder and tool carrier

- High quality coated tool body for complete protection from corrosion

- Through tool coolant supply to the cutting edge

- For cutting speeds up to 2,000 m/min

EWE 2-152 Digital Fine Boring Heads

-

EWE digital fine boring heads connect to BIG KAISER's user-friendly smartphone and tablet app, making it easier to monitor and configure the head while assembling and running boring tools. As well as being able to read changes in cutting diameter, the app helps operators determine optimal cutting parameters from their tool assemblies. The app also logs historical adjustments for all tools ever synced with it, providing essential information for companies adopting smart manufacturing.

Learn more about the BIG KAISER Boring Tool App

Variable tool length adjustment of the tool holder

Best cutting results are only reachable if the tool holder is as short as possible. EWE digital fine boring heads feature variable length adjustment of the tool holders which ensures the shortest and therefore the most rigid tool assembly.

Fine balanced when tool carrier is set in center position

Tool holders made of carbide with adjustable insert holders permit diameter setting on the insert holder. The heavy tool holder remains in the center position and does not create any imbalance. The imbalance created by the insert holder is in most cases insignificant.- Same accessories for precision boring heads EWN

- Indirect and distortion free locking of the tool carrier

- Large dial disc for a parallax-free reading of the adjustment and vernier

- Digital readout

- Wireless connection to BIG KAISER App

EWE 41-203 Digital Boring Heads

-

Easier, faster, safer

Thanks to the large display on these digital boring heads, machining of extremely precise bores has become very easy. Moreover, the user friendly digital display shortens the time for adjusting the boring head by at least 20%. Thanks to intelligent electronics with automatic switch off function which, automatically stores the last displayed value, operator error can be drastically reduced.- Large work range due to 3 different insert holders for each boring head

- Insert holder can be mounted in opposite direction for an easy changeover to back boring

- Wireless Connection to BIG KAISER App

EWN 04-152 Boring Heads

-

Fine boring heads with centric boring bars in modular and integral execution

Variable tool length adjustment of the tool holder

Higher rigidity, and in turn better cutting performance, can be achieved by keeping tool assemblies as short as possible. EWN boring heads feature variable length adjustment of the tool holders which ensures the shortest and most rigid tool assembly.

Fine balanced when tool carrier is set in center position

Tool holders with adjustable insert holders permit diameter setting on the insert holder. The heavy tool holder remains in the center position and does not create any imbalance. The imbalance created by the insert holder is in most cases insignificant.

Large dial disc for a parallax-free reading

Thanks to the use of a vernier scale, diameter adjustments of 0.001 mm can be executed precisely.- Same accessories for fine boring heads EWN and EWE, series 112

- Indirect and distortion free locking of the tool carrier

- Large dial disc for a parallax-free reading of the adjustment and vernier

EWN 20-203 Boring Heads

-

Multifunctional for highest precision and efficiency

The EWN single cutter boring tool program for finishing covers an impressive diameter range with only 7 precision boring heads. Large work range due to 3 different insert holders for each boring head. Insert holder can be mounted in opposite direction for an easy changeover to back boring.- Large work range due to 3 different insert holders for each boring head. Insert holder can be mounted in opposite direction for an easy changeover to back boring

- Highest accurate, purely radial cutting edge adjustment by means of a ground and play free micrometer spindle

- High quality coated tool body for complete protection against corrosion

EWN/EWD Smart Damper

-

EWN/EWD SD 32-150

The EWN/EWD Smart Damper dampens vibrations and reduces chatter in deep-hole finish boring and extended-reach face milling applications – thus achieving better surface finishes and improved metal removal rates.

For precision machining of deep bores, it has previously been necessary to choose low cutting variables in order to prevent vibrations, which massively increases cycle time. The EWN/EWD Smart Damper overcomes this problem, and enables high cutting parameters to be used. This means that extremely short cycle times can be achieved, which improves productivity by up to a factor of ten.- Patented Smart Damper technology for vibration free boring

- Coated tool body for complete protection against corrosion

- Body protection grade: IP 69K

- Direct measuring diameter allows corrections in both directions

Fine Boring Series 318

-

Precision boring head Series 318

The Fine Boring Series 318 system is super light providing high precision and performance, and features through-tool coolant supply to the cutting edge. The system consists of a small number of modular components, including a steel flange, aluminum extension slides, aluminum counter-weight, aluminum precision boring head and a steel insert holder.

Most components are universally utilized with the specific bore diameter being dependent only on the selection of the appropriate slide. The mounting components are pinned to fit onto specific locations on the slides, and secured with steel bolts. Accessory insert holders allow the system to perform face grooving.

The precise positioning of the components on the slide along with incremental adjustment scales for insert holders permit diameter and length setting without a tool presetter. The simple handling of components virtually eliminates operator error during assembly, which leads to safe operation.- Highly accurate and purely radial cutting edge adjustment

- Tool body made of hard-coated aluminum

Turning/Grooving/Charming/Back/Drilling

OD Turning

-

Pin-turning with boring heads

The BIG KAISER modular tooling system offers standard solutions for OD turning on machining centers. The intermediate and large diameter systems allow the use of two TW series heads for balanced roughing and all finish turning assemblies have counterweights available to balance the assembly for higher speed operation.

Attention: Counter-clockwise rotation of spindle!

The series 112 heads also feature a telescopic adjustment of boring bars into the head, allowing unrestricted setting length of each bore depth.

Face Grooving

-

Single cutter high precision face grooving

Single or dual cutter face grooving – the perfect solution to make grooves for O-rings.

Coolant supply directly to the cutting edge

Chamfering Accessories

-

Use versatile chamfering accessories to make your boring head ready for chamfering. Chamfering insert holders are made for front and back chamfering on the twin cutter roughing heads Series 319 SW41-SW148 and covers a wide diameter range. The desired chamfering angle is adjustable from 15º-75º.

The set contains one insert holder and one blank piece.

Existing tools can now be easily retrofitted to perform an additional fixed 45 degree chamfer in the same boring operation

Back Boring

-

In some cases, simply modifying your boring head to a back boring tool is much faster than changing the workholding. Check out our accessories for efficient back boring.

Back boring with the center mount tool simply requires a new back boring insert holder mounted to the tool holder

Drilling

-

Every perfect bore starts with a hole–some of them need to be achieved by drilling. Get an overview on our indexable insert drills with modular CK connection.

- Through tool coolant to cutting edge guarantee optimum cooling and chip evacuation

- Special hardened steel for maximum rigidity and toughness

Accessories for Boring Tools

- BIG KAISER offers accessories for boring tools, spare parts and a unique line-up of economical accessories designed to optimize your productivity and help you operate at peak efficiency.

Boring Inserts

-

For individual tool combinations, comprehensive cutting data tables with detailed information about selection of insert, cutting speed, feed, stock allowance, etc. for different cutting methods are available on request.

Various geometries available in coated grades for your boring applications

Cutters

-

Carefully selected cutters to suit our high precision fine boring heads for micro applications.

Insert Holders for boring ranges 2.0 - 152 mm.- For Boring Range 0.4 - 152 mm

High Precision Boring Head Kits

-

These ready-to-go high precision boring head kits provide everything you need to tool up for boring jobs in an extraordinary range of diameters.

The tooling and carefully selected accessories come stored in a molded plastic carrying case with foam inlay to keep the components organized and to protect the instruments when not in use. The kits also include inserts suitable for fine boring of general steel and cast iron.

The only necessary item not included is the shank, which must be purchased separately. Simply select the shank that matches the taper of your machine spindle, and the gauge length that you require.- Achieve a wide range of diameters out-of-the-box

- Can be expanded to reach an even wider range of diameters

- Protective case keeps components safe and organized while not in use

- More economical than purchasing components individually

Setting Jig

-

The setting Jig can be easily assembled on the front face of the boring heads EWN/EWB 2-50.

Set the measuring slide to the required projection length. Pull the tool holder until the cutting edge touches the lower end of the measuring slide. Align the cutting edge with the edge of the measuring slide.

The scale on the measuring slide provides a coarse diameter setting.- Coarse diameter setting

- Alignment of the cutting edge

- Setting of tool length

Angle Heads & Speed Increasers

-

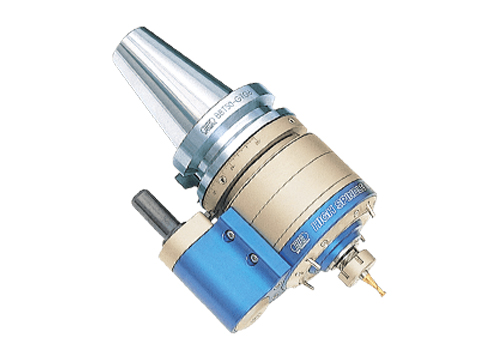

Optimize your spindle with BIG KAISER's Angle Heads & Speed Increasers. Harness your machine's current capabilities by adding an Angle Head. Without the expense of a new machine, you'll be able to perform vertical, horizontal and angular operations on your machine without repositioning the workpiece.

Perhaps you are looking to boost the speed of your existing machine. Our Speed Increasers can increase your speeds up to 100,000 - 120,000 RPM as well as provide dramatic enhancements to surface finish quality and extended tool life. Speed Increasers provide all the performance benefits of a high-speed spindle without the increase in load, greatly extending the life and performance of your machine. Fixed 90° Angle Heads

- Angle Heads fixed with a 90° spindle angle, combine vertical and horizontal operations on one machine. They increase productivity by easily changing the angle of the cutter while utilizing the original workpiece setup. This improves overall accuracy and eliminates the potential for error created by multiple setups. Coolant through the spindle variation of the Build-Up and HMC type angle heads allow for 1,000 psi coolant through the machine tool spindle and out an adjustable port above the cutting tool.The compact design minimizes overhang adding rigidity and strength, as does the standard BIG-PLUS® shank for different interfaces. Three AG90 types available: NBS Type, HMC Type and Build-Up Type.

Center Through Typ

-

Angle Heads

Center Through Type Angle Heads eliminate multiple set-ups and combine vertical, horizontal and angular operations on one machine. One original set-up saves time, speeds production and guarantees better accuracy.

Superior Quality Components

For smooth and powerful operation and to minimize noise and vibration, all Angle Heads are equipped with hardened and ground chrome-nickel steel spiral bevel gears, super precision hardened and ground spindles, and high precision angular contact ball bearings.

Build-Up & HMC Types

Overhang is minimized for added rigidity and strength. As a result, the projection length with the cutting tool is shorter, which reduces the overall load on the Angle Head and thus improves the unit’s cutting capabilities. Further, the minimized overhang helps eliminate interference with the ATC (automatic tool changer) and connecting storage pockets in the tool magazine. The High Rigidity S-Type has a steel housing and a stronger locating pin assembly.- Allows for 1,000 psi coolant through the machine tool spindle and out an adjustable port above the cutting tool

- Coolant piping to the Stop Block is not required

- Great for applications where increased rigidity is required, coolant through spindle capable

New Baby Chuck Type

-

Angle Heads

New Baby Chuck Type Angle Heads utilize the outstanding rigidity and accuracy of the New Baby Chuck and New Baby Collet, producing high precision with less runout. A wide variety lengths and capacities are offered for 40 and 50 taper models. We recommend this type for small drills and light milling operations.

For greater rigidity High Rigidity S-Type with a steel housing and a stronger locating pin assembly is also available.- Outstanding rigidity

- Uses standard New Baby collets

- Many lengths and capacities available

HMC Type Angle Heads

-

For Heavy Duty End Milling

In the AG90 series, HMC Type Angle Heads offer the combination of power and large diameter tool capacity, using BIG KAISER’s Hi-Power Milling Chuck system. The HMC type Angle Head has a maximum speed of 3,000 RPM.

Greater versatility is obtainable with a milling chuck by utilizing Straight Reduction Collets and other accessories. A High Rigidity HMC Type is also available with a steel housing and reinforced locating pin assembly for heavier machining.- Combines horizontal and vertical operations in 1 setup

- Wide range of tapers, lengths and designs

- Automatic Tool Change with stop block

- Superior quality components

Build-Up Type Angle Heads

-

Build-Up Type Angle Heads can be fitted with a wide range of adapters to cover most machining requirements including New Baby Chuck, Hi-Power Milling Chuck, Shell Mill Arbor, Auto Tapper Type B and more. The angle head output is equipped with a short taper for quick changing of various adapters. A High Rigidity Build-Up Type is also available for heavier machining.

- Various adapters for multiple operations (Build-Up Type)

- Wide range of tapers, lengths and designs

- Easy and precise setting of cutter directions

- Automatic Tool Change w/ stop block

Small Bore Type Angle Head

-

Reduced Body Size

The Slender Drive or small bore type angle head is designed to get into narrow spaces with limited clearance. The reduced body of the Slender Drive offers a higher degree of flexibility to machined components by allowing 90° cutting operations inside small bores. It offers a maximum speed of 2,000 RPM and is designed for drilling and light milling operations.- Six output attachments to choose from, three small and three large

- Automatic Tool Change w/ stop block

- Fixed 90° spindle with cutter head adjustable a full 360°

- BIG-PLUS® is standard

- Superior quality components

Universal Type Angle Heads

- Universal Type Angle Heads, with an adjustable spindle combine vertical and horizontal operations on one machine. They increase productivity by easily changing the angle of the cutter while utilizing the original workpiece setup. This improves the overall accuracy and eliminates the potential for error created by multiple setups. BIG-PLUS® is standard, ensuring rigidity and accurate automatic tool changes.

AGU90 Type Angle Heads

-

Adjustable from 1° - 90°

AGU90 Type Angle Heads, with an adjustable spindle, (1° - 90°, 1° increments), combine vertical and horizontal operations on one machine. They increase productivity by easily changing the angle of the cutter while utilizing the original workpiece setup. This improves overall accuracy and eliminates the potential for error created by multiple setups. BIG-PLUS® is standard for all SK & BT versions, ensuring rigidity and accurate automatic tool changes.- Combines horizontal, vertical and angular operations in 1 setup

- Easy and precise setting of spindle angle

- Advanced non-contact seal prevents coolant and particle contamination

- Excellent runout control

- BIG-PLUS® is standard for added rigidity

- Automatic Tool Change

- Spindle is adjustable for all cutting angles 0° - 90° in 1° increments

- Cutter head adjustable full 360°

- Unique coolant jacket

- Superior quality components

- Utilizes New Baby Collet

- 6,000 RPM for 40 taper

- 4,000 RPM for 50 taper

AGU30 Type Angle Heads

-

Adjustable from 0° - 30°

Universal AGU30 Type Angle Heads use a unique constant velocity joint to shed weight and allow for higher performance than other angle heads. The joint transmits enough torque to outperform traditional, spiral beveled gear 90° angle heads, while a low backlash design means better surface finishes with fine milling. The flange structure keeps rigidity at a constant despite the angle of the head, unlike a swing structure in which rigidity is dependent on the cutting direction. Also, because the mechanism is sealed, the AGU30 provides better coolant and chip proofing.

The spindle angle is adjustable from 0° - 30°, and is easily adjustable using the scale indication on the body. The cutter head is adjustable a full 360°.- Features a unique constant velocity joint

- Higher torque than traditional spiral beveled gear heads

- Low backlash design for better finishes

- Rigid flange structure

- Sealed for better coolant and chip proofing

- Light weight with superior performance

≤20,000 RPM

- High Spindle speed increasers maximize the performance of your high efficiency cutting tools that were developed for advanced high speed machining.

High Spindle Speeder Increasers

-

Multiply Existing Spindle Speed

High Spindle speed increasers maximize the performance of your high efficiency cutting tools that were developed for advanced high speed machining. The continuous use of machine tool spindles at high RPM's results in a shorter life span of the spindle due to excessive load to its motor and bearings. High Spindle reduces this load and greatly extends the life of the expensive machine tool spindle.- Multiply existing spindle speed 4, 5 or 6 times

- Reduced load to machining center spindle

- High durability through advanced sealing method

- Minimal heat generation

- Maximize performance of cutting tools

- Reinforced planetary gear driving system

- High torque transmission

- Multi-directional coolant supply

- High precision New Baby Collet system

≥40,000 RPM

- Air driven high speed micro machining spindle speeders provide improved cycle times and finishes over conventional machine tool spindles.

RBX5 / RBX5C

-

An air power spindle for high speed micro machining with a Ø 1.5 mm (Ø.059") or small cutter at speeds of 40,000 to 50,000 RPM.

Available as:

Center Through Type - Compressed air through the machine spindle

Side Through Type - Compressed air through the stop block

Manual Tool Change Type- Compressed air through machine spindle

- Outstanding dynamic runout accuracy

- Minimized Z-axis thermal displacement

- Extended tool life

- Superior surface finish

- Ultra high-speed and precision

- Automatic Tool Change with stop block

- Ultra-low vibration

- Low noise design (within 65 dB)

RBX7 / RBX7C

-

An air power spindle for high speed micro machining with a Ø 1 mm (Ø.039") or small cutter at speeds of 60,000 to 80,000 RPM.

Available as:

Center Through Type - Compressed air through the machine spindle

Side Through Type - Compressed air through the stop block

Manual Tool Change Type- Outstanding dynamic runout accuracy

- Minimized Z-axis thermal displacement

- Extended tool life

- Superior surface finish

- Ultra high-speed and precision

- Automatic Tool Change with stop block

- Ultra-low vibration

- Low noise design (within 65 dB)

RBX12 / RBX12C

-

An air power spindle for high speed micro machining with a Ø 0.61 mm (Ø.024") or small cutter at speeds of 100,000 to 120,000 RPM.

Available as:

Center Through Type - Compressed air through the machine spindle

Side Through Type - Compressed air through the stop block

Manual Tool Change Type- Compressed air through the machine spindle

- Outstanding dynamic runout accuracy

- Minimized Z-axis thermal displacement

- Extended tool life

- Superior surface finish

- Ultra high-speed and precision

- Automatic Tool Change with stop block

- Ultra-low vibration

- Low noise design (within 65 dB)

Measuring Instruments

-

We offer many high precision measuring instruments that make your work flow faster, more accurate and more efficient.

Add a tool presetter into your work flow to dramatically increase productivity. Preset your tools for the next job while your machine continues cutting—eliminating test cuts.

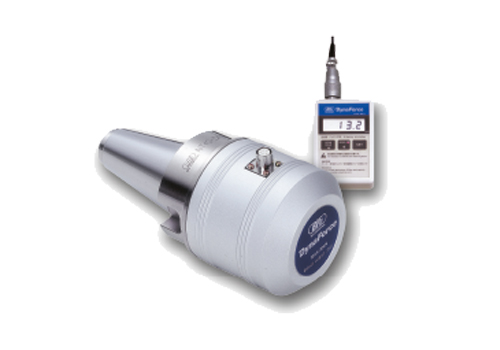

Ensure that your machine spindle is operating properly with our spindle measurement tools. Make sure your tools are aligned in the spindle and the retention force is correct. Tool Presetters

-

Tool Presetters measure the cutting edges of your tools to assure they precisely match job specifications and are ready to be used in the machine. Adjustments that could take up to 15 minutes when made on your machine can be made offline in less than a minute on a presetter, while your machine continues cutting.

Why Preset Tools?- Reduce tool cost - increase tool life

- More spindle uptime - no more measuring on your machine tool

- Precise and repeatable measurements

- First part precision - adjust tools to within tolerance and run your part

- Eliminate test cuts

- Increase operator and overall efficiency

Advanced Models

-

Speroni FUTURA is the standard by which all other tool presetters are measured. FUTURA is a high precision modular tool presetting system designed to increase profits and available machining time. All Speroni FUTURA advanced models can achieve repeatable precision of 1 micron or better when measuring tools.

Speroni offers state of the art solutions guaranteeing greater added value to our customers since 1963. Speroni designs and manufactures highly reliable products of exceptional quality thanks to the use of advanced technologies. Speroni is a benchmark for innovation, precision, longevity, and value in the international field measurement, presetting and tool management.

Tool Offsets

-

Measure tool offsets with these high precision compact sensors which ensure fast and accurate operations. They allow you to touch off a tool without the risk of damaging or breaking the tool and are available in different executions.

Reduce your setup time with your lathe using Lathe Master or the Centering Tool.

Base Master Series

-

Tool Offset Sensor

Base Master Series is a precision touch sensor to determine workpiece offsets and tool length. They can be mounted on workpiece surface or machine table. An LED lamp illuminates immediately when the cutting edge touches the sensor plate and the position is detected.- Preset tools to within +/- 0.005 mm

- LED lamp illuminates at exactly 2.000" from the reference surface

- Repeatability of1 µm

- Greatly reduced setup time

- Compact design for fast and easy handling

- Safety over-travel of sensor plate prevents damage to tools

- Magnetic base mounts vertically, horizontally, or at any angle

Centering Tool

-

Static Dial Gauge for Easy Centering

With this innovative centering tool spindles and tools can be centered—ideal for limited spaces within small lathes.- Reduce setup time

- Centering the tool holder is simplified since the dial gauge position is static and in front

- Easy setting with a fine adjustment mechanism

- Magnetic base allows for flexible mounting positions

Lathe Master

-

Lathe Master provides quick setup of the cutting edge position without trial cutting. Capable of measuring external, internal and facing tools. An LED light illuminates when the tip of the tool touches the sensor plate.

- Effective setup reduction for NC lathes

- Detectable with various tool bits for external, internal and face turning

- LED light feedback

- For electro-conductive Machines and tools

Tool Master

-

Tool Master is a precision touch sensor with a large dial gauge. LED lamp and sound pre-indicate approach to 100 mm height to ease the detecting operation.

- Approach LED lamp and sound

- For all materials, including non-conductive cutting tools, workpieces, and machine tools

- Large dial is easily viewed

- Magnetic base mounts vertically, horizontally, or at any angle

Dyna Line Portable

Dyna Line Portable

-

Precision Measuring of Tool Diameter and Runout Accuracy

Dyna Line Portable eliminates machining defects by measuring total runout accuracy at high rotation speeds. Also usable as a maintenance / evaluation tool for runout accuracy of machine spindle.

The innovative linear image measuring method

CMOS sensors are often found in hi-tech equipment such as digital cameras and smart phones. With pixels measuring 1.4 μm, Dyna Line uses the latest CMOS sensors for quick and precise measuring.- Non-contact measuring with CMOS linear image sensor

- In-machine measuring

- Portable (usable with 6 C-Cell batteries)

Edge and Point Finders

Edge and Point Finders

-

Finding the edge of the workpiece is crucial to making accurate cuts. Manually finding an edge or point can be time consuming and difficult. Fortunately, we offer edge and point finders to quickly and accurately find the edge or point of a workpiece.

These tools are high precision touch sensors to quickly find measurement locations before machining.

Spindle Measurement

Spindle Measurement

- Regular spindle measurement is a necessity. Periodical measurement of the spindle retention force avoids unknown reduced rigidity, which leads to vibrations, loss of machining quality and shortened tool life. A full length taper stabilizes the value of measurements.

Level Master

Level Master

-

Precision Leveling Instrument

Level Master is a 2-axis simultaneous detection leveler. LED displays level conditions for both axes simultaneously. LED and buzzer indication when leveling is completed.- 10 micron per meter precision (.01mm/m)

- Simultaneous 2-axis detection with .01mm/m ultra high precision

- LED and buzzer indication when leveling is complete

- Uses optical level sensor technology

- Level condition is indicated without delay

- Low and High Mode for coarse and fine adjustment

Accessories

-

When purchasing new equipment, it is typical to spend a great deal of time researching which machine offers the specifications and features to meet your needs. But once you've purchased a machine and installation is complete, what should you be doing to maximize its performance?

BIG KAISER offers a unique line-up of economical accessories designed to optimize your productivity and help you operate at peak efficiency.

We offer many ingenious set-up accessories like Base Master and Tool Master compact sensors that make your work flow faster and more efficient.

To keep your machines running smooth and operating at top performance, don't forget our unique line of clean-up accessories.

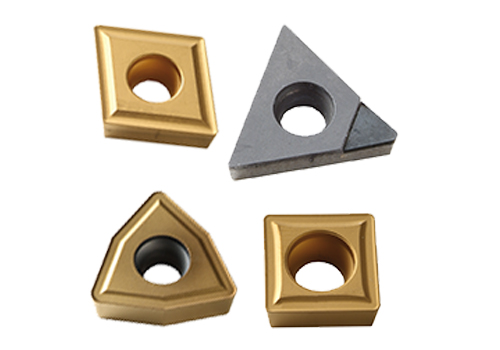

Inserts

-

Choosing the right inserts and grade is an important part of your manufacturing productivity. Our insert selection contains a large assortment of insert types, sizes and grades to fit most applications.

Face grooving with boring tools is generally more efficient than milling with circular interpolation, especially when manufacturing grooves of large diameters.

Pullstud Bolts

-

High Tensile Strength

Strong centrifugal forces at high speeds can pull tool holders out of the machine spindle. Therefore, high tensile strength pullstud bolts are recommended to protect against this possibility. Our pull studs utilize H13 tool steel, which improves their tensile strength.

Most breakage occurs due to impurities in the material. Impurities eventually become cracks due to strong cutting and vibration forces. Other reasons for breakage are caused by dents created from ball clamp retention systems, compared to dual contact collet-type systems. Coolant alkaline levels will also contribute to shortened life span.

BIG Daishowa pullstud bolts are 98% pure and contain no lead. Our pullstud bolts have a high nickel alloy content which provides up to 30% higher strength than those not containing nickel.

Additionally, BIG pullstud bolt threads are roll formed which provides 30% higher strength and excellent thread quality, compared to others which are cut threaded.- Improved tensile strength

- Roll formed threads

- Smooth surface prevents notching effect

- Laser marking for manufacturer ID

- Wide selection for specific machine models

Collets

-

A Variety of Collets for Tool Holders

In 1987, BIG Daishowa was the first company in the world to laser mark the collet grade on every collet.

Today, BIG KAISER offers a variety of collets that are available in 0.1mm diameter increments to suit all cutting tool shank sizes with maximum accuracy. Despite their compact size, high clamping force and accuracy are achieved.