- Offer Profile

-

Since 1961, when HEULE Werkzeug AG was initially set up as a contract manufacturing business, its goal has been in reducing production times. In order to cover our own needs, we developed tools that can front and back deburr, chamfer and countersink in one operation.

HEULE is committed to the values of quality, precision and service. Competent service, fast delivery times, and customized solutions are the highest priorities. From all ranks, HEULE's commited and motivated expert staff carry out their work with reliability and professionalism.

Deburring

-

Uniform deburring on both sides in a single pass, without rotating the workpiece.

Your advantages when deburring with HEULE

The high cost-effectiveness and reliability of HEULE deburring tools are impressive. We have a solution for a wide range of applications.

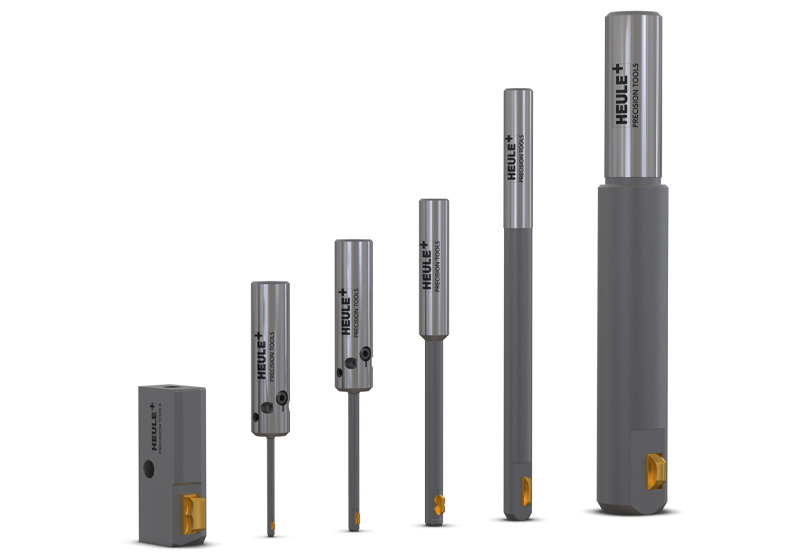

COFA

-

Forwards and backwards deburring of even and uneven bores in one single pass

- No need to rotate the workpiece or stop the spindle

- Radius-shaped deburring profile

- Standard range from bore diameter 2.0 mm

- Cassette solutions from bore diameter 10.0 mm to any size.

Range

The range includes deburring tools for use on bore diameters from 2.0 mm to 26.0 mm. Any size bore diameter can be deburred using cassettes. The deburr size ranges from 0.1 mm to a maximum of 1.4 mm radially, depending on bore dimension and blade selection. The blades are available for both forward and backward cutting, as well as backward cutting only. The COFA operates reliably in both CNC and manual operations. The COFA is used for deburring bores in metal or other materials.

DL2

-

Forwards and backwards deburring of even and slightly uneven bores in one single pass

- Deburring of bore diameters from 1.0 mm – 2.1 mm

- Maximum blade life thanks to integrated cooling of the cutting edge

- Very short cycle time

- Simple blade change directly in the machine

Range

The demands on the deburring quality of the smallest bores are increasing all the time – such as in medical and electronic applications, the aircraft industry and the luxury watchmaking industry.

The DL2 with its operating principle offers the appropriate solution with a wide range of workpiece materials such as steel, stainless steel, titanium, aluminium or composite materials. The range includes tools for use on bore diameters from 1.0 mm to 2.1 mm. The working lengths range from 3.0 mm to 10.0 mm. The deburring size is approx. 0.15 mm radial.

X-BORES

-

Customer-specific deburring solutions for intersecting bores or crossbores

Field of application

Modern components have increasingly complex geometries. Alternative deburring techniques, such as thermal deburring and electrochemical deburring, frequently require complex processing steps outside the machining centre. However, even existing mechanical technologies quickly reach their limits when confronted with such challenges. With X-BORES technology, however, the workpiece is completed on the machine, saving both time and money.

Crossbores 1:1 / COFA-X

The mechanical deburring tool for crossbores up to a bore ratio of 1:1.

COFA-XIntersection / SNAP-X

Deburring of several crossbores that all penetrate into a main bore. This is a custom development.

Custom developmentOil bores / CBD

Deburring of classic oil bores as well as very complex bore intersections. This is a custom development.

Custom development

Chamfering

-

Economical front and back chamfering of bores in a single pass.

Your advantages when chamfering with HEULE

The HEULE chamfering tools remove the burr from the front and back bore edges and produce a chamfer. They are renowned for their exceptional cost effectiveness.

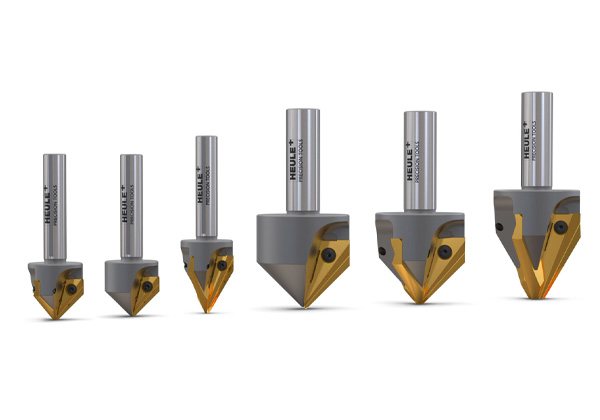

SNAP

-

Forwards and backwards chamfering in one single pass

- No need to rotate the workpiece or stop the spindle

- Carbide blade that can be changed by hand in the machine

- Particularly suitable for CNC operations with large batch sizes

- Standard range from bore diameter 2.0 mm

- Cassette solutions from bore diameter 12.6 mm to any size

Range

The range of tools includes chamfering tools for bore diameters from 2.0 mm to 35.0 mm. Using cassettes, bore diameters of any size can be chamfered. Depending on the type of blade, the chamfer size ranges from 0.2 mm to 1.5 mm. The chamfer size and angle are geometrically defined on the SNAP blade and can only be changed by using a blade with a different geometry.

DEFA

-

Forwards and backwards chamfering of interrupted bores – even with large burrs – in one single pass

- Secondary burr-free processing of demanding materials with large burr formation

- Dimensionally stable chamfer with high-quality chamfer surface

- Chamfering capacity continuously adjustable, depending on the bore dimension from 0.1 to 2.0 mm

- Standard range for bore diameter 4.0 mm – 23.9 mm

Range

The DEFA range consists of three tool series, each covering a certain bore diameter range. The chamfering capacity is variable and infinitely adjustable directly on the tool, ranging from 0.1 to 2.0 mm, depending on the bore diameter.

Counterboring

-

Back counterboring of bores without rotating the workpiece

Your advantages when counterboring with HEULE

A wide variety of applications can be solved with the HEULE counterboring tools. The back counterboring tools are extremely reliable.

BSF

-

Backspotfacing up to 2.3 x the bore diameter

- Without rotating the workpiece

- Standard range for bore diameter 6.5 mm – 21.0 mm

- Reliable backspotfacing or counterboring

- Designed for automatic operation

Range

The standard range consists of back counterboring tools for use with bore diameters ranging from 6.5 mm to 21 mm in 0.5 mm increments. The maximum possible counterboring diameter is 2.3 times the bore diameter. The tools can be activated both by internal coolant pressure ( min. 20 bar, max. 50 bar) or compressed air (min. 6 bar).

SOLO

-

Forwards and backwards counterboring and backspotfacing in one single pass. Interrupted cutting possible

- Extremely robust system, also for materials that are difficult to machine

- Field of application from bore diameter 6.0 mm

- Maximum countersink diameter 49.0 mm

Range

The SOLO counterboring tool is available in two variants. On the one hand, there is SOLO for machining materials at high cutting speeds and on the other, SOLO2 for machining at low cutting speeds.

GH-K

-

Countersinking of metal from Ø3 mm to Ø45 mm

- Countersink range from Ø3.0 – Ø25.0 mm or Ø4.0 – Ø45.0 mm

- Three interchangeable, precisely matched carbide blades

- Internal cooling available

- Circular milling possible

Range

The range consists of two types: a countersinking tool with three cutting edges and a countersinking tool with only one cutting edge. Each design is available in two versions with a countersink diameter range from 3.0 – 25.0 mm and another from 4.0 – 45.0 mm. The HEULE countersinking tools are available with countersinking angles of 60° and 90°.

Drilling combined

-

Economical drilling combined with deburring, chamfering or countersinking.

Your advantages when combining with HEULE

HEULE's combination drilling tools simplify production processes by combining drilling with deburring, chamfering or countersinking.

VEX

-

Drilling combined with front and back chamfering in a single pass

- Bore diameter 5.0 mm – 11.5 mm, drilling depth up to 2xd

- Easy-to-change carbide twist drill insert tip

- Short set-up and non-productive times thanks to simple handling

- Reduced process times thanks to multifunctional processing in a single pass

Range

The standard range includes tools for bore diameters from 5.0 mm to 11.5 mm. They are available in versions with a drilling depth of 1xd or 2xd. The corresponding drill insert bits are available in 0.1 mm diameter increments. The blades for chamfering correspond to the SNAP5 series. These are available from a diameter of 5.5mm x 90° in 0.5 mm increments and in forward and backward cutting or backward cutting only versions. The chamfer size and angle are geometrically defined on the blade and can only be changed by using a blade with a modified geometry.

Applications

-

Our solutions in action

Our aim is to provide you with a tool solution that is perfect for your application. Regardless of the industry you work in. Regardless of the material being processed. See for yourself where our tool solutions are in use.

Fitting / Hydraulic T-Piece

-

Automated deburring of crossbores: X-BORES ensures a safe and reliable process.

Alloy wheels

-

Thanks to the custom development of a combination tool, process costs and cycle times have been reduced.

Railway line

-

The HEULE solution automates the chamfering of both sides of the bores for stable and reliable process. Due to mechanical deburring, it is no longer necessary to purchase new machines.

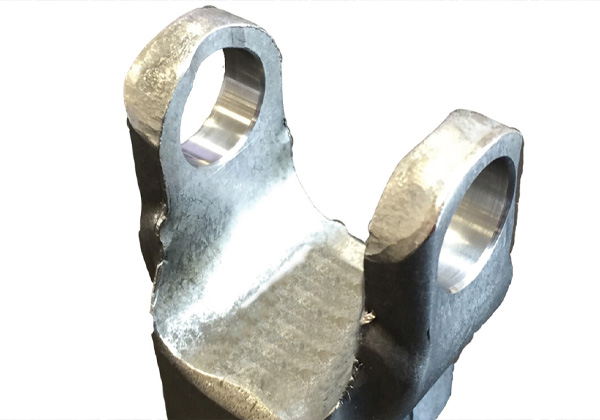

Fork piece

-

Through process-reliable deburring and the elimination of manual rework, time is saved.

Watch case

-

Process-reliable series production of smallest bores

Steering Knuckle

-

Increased economy thanks to the HEULE chamfering solution.

Shell ring connector

-

Drilling, forward and backward chamfering simultaneously: Cost reduction of more than USD 100,000 per year.

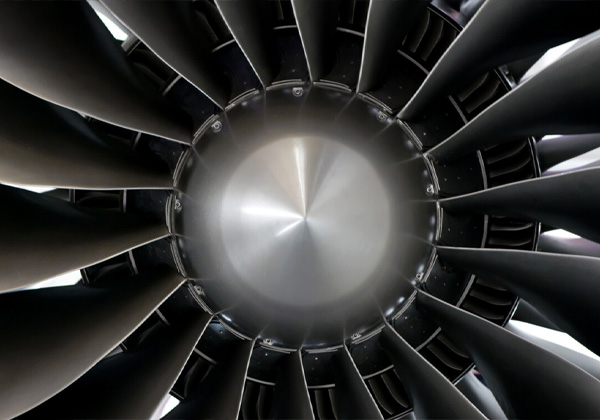

Low pressure turbine stator housing

-

75% reduction in machining time per bore.

Back implant

-

PEEK is a demanding material used in medical technology. HEULE offers the customer the optimal solution for deburring bores

Helicopter component

-

Off-machine production provides time and quality gains.

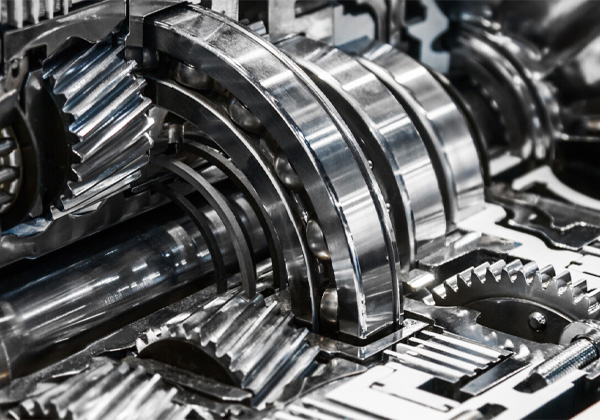

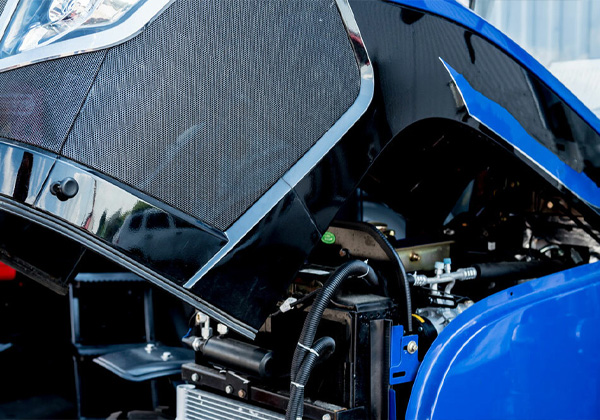

Gearbox components for tractors

-

The customer processes eight components per re-clamping with the complete solution.

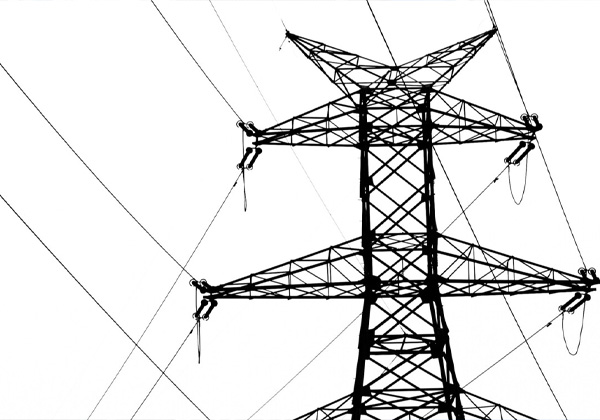

High-voltage conductor cable

-

Avoid re-clamping by back spotfacing: The customer can manufacture the entire 500-piece batch without interruption or blade change.

Brake disc

-

Multiple work steps in a single tool for maximum cost efficiency.

Medical technology trays

-

A tool that combines drilling and deburring in a single pass eliminates the need for manual deburring.

Sprocket wheel

-

34% cycle time reduction.

Crankshaft

-

The replacement of manual processes with automated ones.

Knee joint replacement

-

The specified service life of 20 workpieces per blade could be significantly exceeded with over 60 workpieces.

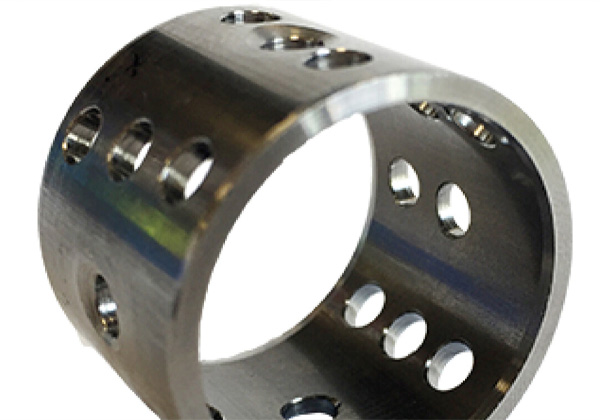

Bearing bushing

-

Cycle time improved by 20%.

Manifold

-

Mechanical deburring to replace costly thermal deburring.

Flow meter

-

Drilling and defined chamfering combined in one tool.

Elevator trailing wheel

-

Process optimisation: repeated alignment and clamping are no longer required.

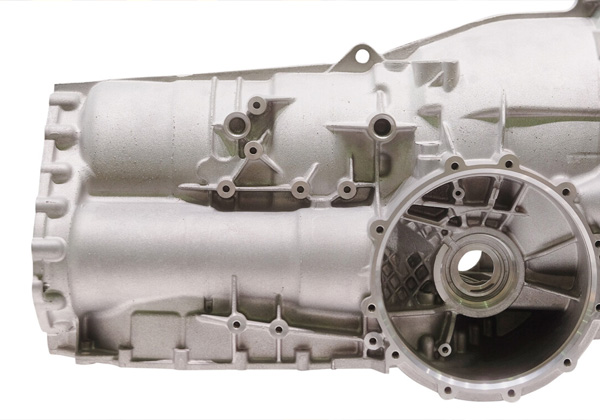

Gearbox housing

-

Cycle time savings and improved process reliability.

Chain wheel drum

-

Process-reliable counterboring solution for bolt connections.

Aircraft component

-

The replacement of the manual chamfering process has reduced production time.

Common rail

-

In the low-pressure range, diesel fuel distribution systems also require cleanly deburred bores.