- Offer Profile

-

We are a leading provider of industrial storage and shelving, expertly designed and engineered to enable businesses to increase capacity, productivity and efficiency.

Whatever your storage needs, Dexion has all the products, solutions and accessories you need to make the most out of every section of available space in your storage area.

As a key part of the Gonvarri Material Handling group, we’ve helped some of the worlds' leading brands and pioneering SMEs, providing them access to global expertise and support. We work with our customers through the complete lifecycle of their storage needs, from initial planning through to installation and ongoing service and support. We are committed to developing storage solutions that help our customers work more quickly and efficiently whilst becoming more profitable. Simply put, we make it work!

Pallet Racking

-

Find the perfect fit pallet racking storage solution for your requirements. Pallet racking can be easily configured in a variety of ways based on your needs and pallet load, to ensure a functional and logical warehouse storage solution for you.

Whatever the industry, there's a range of storage systems that can provide optimal storage economics. From Drive-in Racking or Mobile Racking (MOVO) for frozen and cold-store goods; to First-in, First-out (FIFO) Pallet-flow systems for bulk goods such as those with a "best before date".

Standard Wide Aisle Pallet Racking

-

P90 Standard Wide Aisle Pallet Racking provides your warehousing teams with unrestricted access to all your pallets at all times. The system delivers versatility and assembly as single- or double-depth racks.

P90 Pallet Racking easily adapts to your specific warehouse and storage requirements, thanks to a variety of widths, depths and heights. In fact, P90 Racking will fit into any space available, and is suited to all kinds of pallets – whether they be Euro, Chep, disposable or captive pallets, mesh boxes or bins. The modular, future-proof system adapts perfectly to your particular needs – thanks to different beams, angle supports and shelves and extensive accessories range.

P90 Standard Wide-Aisle Racking offers the following features and benefits as standard:

- Free and unrestricted access at all times

- Optimum adaption for the full range of pallets

- High stability and high-quality workmanship

- Rack heights of up to 30 metres and maximum bay loads of more than 30 tons

- P90 components are permanently protected against corrosion

- Comprehensive range of accessories and complementary features

Narrow Aisle Racking

-

Narrow Aisle Pallet Racking is your ultimate space-saving option if your warehousing or storage floor space is limited. It gives your teams maximum storage capacity, and allows for quick order-picking and fast accessibility to every pallet.

Narrow Aisle Pallet Racking combines a wealth of features to enable the best possible use of space, and fast order-picking. Compact and efficient, it's a construction set-up used in a wide variety of industries where warehousing space is limited. Varying shelving heights and depths, together with height-adjustable supporting beams assure maximum flexibility with man-down, high-lift stackers, or man-up-order-picking stackers. It's a system perfectly suited for convenient pallet storage and retrieval or for fast order-picking straight from the pallet. Handling equipment is often highly automated, and guided by wire or rail.

Narrow Aisle Pallet Racking offers the following features and benefits as standard:

- Total and unrestricted accessibility to individual pallets

- Optimum configuration for maximum storage, density and efficiency

- Any additional costs offset by added value of improved space

Mobile Pallet Racking

-

Mobile Racking (MOVO) is a dynamic solution providing up to double the storage capacity in the same area, of conventional pallet racking. Offering technical superiority and total flexibility, MOVO is suitable for every kind of stored goods, and has a wide range of accessories.

The electronically controlled MOVO high-load racking system runs on in-ground rails and can carry bay loads of up to 24 tons at racking heights of up to 12 meters. While state-of-the-art sensor technology and variable control options ensure ease of operation and absolute safety.

MOVO offers the following benefits as standard:

- Save up to 50% of the space required by conventional pallet racking, and increase storage capacity by up to 80%

- Cuts energy, operating and cleaning costs; allowing for a good ROI

- 100% individual pallet access

- Wide variety of accessories

- Suitable for any kind of warehouse goods

- Guaranteed operational safety of -30° C; ideal for use in cold-storage rooms

- Latest PLC-technology for perfect support of optional functions, plus touch screen with clear graphical display for optimum visibility

- Designed in accordance with the European Directive 2006/42/EG and DIN EN 15095

Pallet Shuttle System

-

The Pallet Shuttle system is a semi-automated, high-density storage solution for the handling of goods inside channels similar to a drive-in or pallet-flow setup. Cost-effective and time-saving, it removes the need for forklift trucks to enter the aisles.

The remotely controlled Pallet Shuttle is a highly efficient alternative to live storage and drive-in racking. The Pallet Shuttle system works either as First in, First out (FIFO) or as Last in, First out (LIFO) for situations such as cold storage, food and beverage production, and meat processing.

Using the Pallet Shuttle system offers the following benefits as standard:

- Cost effective and time-saving; not requiring the use of special forklifts

- Low level of risks or damage to the equipment and operating staff

- Fast and sustainable; automatically handles pallet picking and retrieval

- Offers more effective, high-density storage

- Can pick up, deposit and re-organize pallets with great precision

- Operating temperature ST: 0°C to +45°C / BZ: -1°C to -30°C / Hybrid model can be used in both temperature ranges

- Available in different models designed for various pallet configurations

- Designed in accordance with the European Directive 2006/42/EG and DIN EN 15095

Drive-in Pallet Racking

-

If you're storing large quantities of similar or identical goods, the P90 Drive-in Pallet Racking can free-up as much as 90% of existing floor space, compared to conventional pallet storage.

P90 Drive-in Pallet Racking creates efficiencies by reducing aisle loading and unloading times, yet allowing greater access compared to block-stacking. Positioning pallets on front-to-back rails allows rows to be stacked next to each other safely and efficiently; crucial for items regarded as fragile or unstable.

The P90 Drive-in Pallet Racking offers the following features and benefits as standard:

- More storage per cubic metre than any other storage system

- High density storage - maximising floor and storage space

- Limited stock rotation – ideal for seasonal goods and chilled storage

- Accessible by the FILO principle

- Smooth pallet rails – for safe, snag-free load-bearing

- Brightly coloured pallets help drivers position loads quickly and accurately

Pallet Flow Racking

-

Pallet Flow Racking, or 'Pallet Live Storage' is ideal if you operate a First-in, First-out (FIFO) goods storage setup. With this system you can use up to 60% less space than if you were to use conventional pallet racking.

Our Pallet Flow system offers a dynamic storage solution with integrated conveyor modules to suit most pallet types and sizes. It's well-suited for the drinks industry or as a buffer storage facility in manufacturing.

Pallet Flow Racking offers the following features and benefits as standard:

- Dedicated load and retrieval means only two forklift truck aisles are required

- Uses up to 60% less floor space than conventional pallet racking

- FIFO operation – for automatic stock rotation

- Faster, more efficient warehouse picking speeds

Multi-tier Pallet Racking

-

With Multi-tier Pallet Racking from Dexion, you can create manual pick-lanes for your teams at various levels, by providing walkways built into the pallet racking structure.

Our Multi-tier Pallet Racking offers optimum use of space over that of traditional mezzanine flooring structures and layouts. This type of pallet racking structure creates a number of levels and walkways for storing and collecting goods – everything from cartons and boxes, to garment storage on hangers.

Multi-tier Pallet Racking offers the following features and benefits as standard:

- Combines wooden, mesh, grating or steel shelves depending on requirements

- Increased number of picking levels

- Maximises use of the full height of the building

- Optimises floor space

- Allows order-picking on multiple levels

- Can combine pallet storage and small goods storage

- Removes the need for a mezzanine floor

- Easily incorporates fire sprinkler and lighting systems

- Extensive range of stairs, handrails and pallet gates

Push Back Rollers

-

Push-back Rollers – a dynamic storage solution based on the P90 Pallet Racking System and including wheel/roller conveyors. Ideal if you're storing bulk goods on pallets according to the Last-in, First-out (LIFO) principle.

Once a pallet is picked from the pick-face, the rest roll forward automatically under a controlled speed. Up to 9 pallets can be stacked in this way. Push-back Rollers can also be used to provide additional storage space in otherwise unusable areas, such as above cross-aisles or around dock-levellers.

Our Push-back Rollers offer the following features and benefits as standard:

- Up to 75% increase in storage capacity compared to conventional storage

- Operations reduced to a minimum

- Quick and easy access to all channels

- Maximise floor space

- Ideal for bulk storage and cold store

- Accessible by LIFO principle

- Very high occupancy rates compared to Drive-in Racking or Block-stacking.

Pull-Out Units

-

Our Pallet Pull-Out Units let your teams move pallets back and forth like drawers, even with a full load up to 1000kg. With such efficient storage, they can free up the excessive clearance distance needed above pallets.

The Pallet Pull-Out Unit saves both time and space to ensure an efficient working environment and ergonomic picking. By installing pull-out units in your pallet racking, the number of pallet and picking locations can be increased, while still taking up the same space as before. What's more, shorter operation distances allow for faster and more efficient picking, while at the same time freeing up valuable floor space.

Our Pallet Pull-out Units offer the following features and benefits as standard:

- Increase storage capacity

- Create space

- Allow easy access

- Increase picking rates

Carton Flow Picking Unit

-

The Carton Flow Picking Unit system is a fast and flexible solution for you to transport components to assembly stations without interruption. You can also easily adjust the shelves and wheels to ensure efficient movement of various sized packages. The Carton Flow Picking Unit system is flexible enough to allow for changing and evolving warehouse layouts, thanks to the fact that it can be built as a stationary unit, or supplied with lockable wheels.

The Carton Flow Picking Unit system offers the following benefits as standard:

- Adjustable, ergonomic racks – for ultimate handler efficiency

- Separate loading and unloading – so picking can be carried out uninterrupted on either side

- High packing-density for carton storage – meaning more floor space

- Reduces travel distances and picking times

- Simple, fast installation

- Straightforward, modular system

Speedlock P90+ Pallet Racking

-

Speedlock P90+ Pallet Racking - a versatile solution for static and dynamic pallet storage. Designed for maximum storage capacity and fast availability, it ensures unrestricted access at all times.

Speedlock P90+ Pallet Racking is the most advanced adjustable pallet racking system on the market. Available up to 30 metres and in variable widths and depths, it meets European requirements and provides efficient, flexible solutions for every need.

Speedlock P90+ pallet racking offers the following benefits as standard:

- Optimum customisation – thanks to a range of widths, depths and heights.

- High stability – with rack heights of up to 30 meters and maximum bay loads of more than 30 tons.

- Extensive accessory range – with beams, angle supports and shelf bases, and a large number of safety features.

- Future proofed – modular construction and variable bay sizes to meet changing requirements.

Crane Racking

-

Crane Racking is a fully automated storage system, ideal for storing pallets and large items. Designed to work within very narrow aisles and at a height of more than 30 metres, crane racking is an efficient, optimised storage solution.

Guided by a management software system, the crane travels along the aisles of the warehouse, where it enters, positions and extracts the goods.

For multi-deep configurations, crane racking is equipped with a shuttle which retrieves the pallet and delivers it directly to the front – ensuring maximum accessibility. Crane Racking is designed to offer complete flexibility, from load capacity and building height, to cycle times and temperature control. The system adapts easily to the needs of each warehouse making it a highly effective storage solution for a vast range of applications.

Shelving

-

From a single shelving bay, to a vast installation, Dexion's wealth of expertise and resources ensure your shelving not only meets your requirements right here, right now, but can accommodate your ongoing and changing needs in the future.

In fact, whether your facility operates to a multi-tier or mobile set-up, our wide selection of shelving systems are perfect for small-parts storage, organisation and identification in warehouses and picking areas.

Dexion offers something for everyone, making for a world-class blend of performance, security and economy, all while complying with safe working practices and local requirements and regulations.

Standard Shelving System

-

The Hi280 Standard Shelving system's applications are vast. You can build it as a traditional shelving system; a high-rise installation, or a multi-tier system. Whether you're operating standalone or manually-served picking, or a large, fully-automated central store. Hi280 Standard Shelving is a flexible and versatile storage system for small-parts handling. Eliminating the need for cross-bracing maximises storage for its depth. While pre-galvanized steel results in a high, consistent quality, with a focus on using a minimum number of components as possible.

The Hi280 Standard Shelving system offers the following features and benefits as standard:

- Frame components and shelves manufactured in pre-galvanized steel

- Based on the principle of a minimum number of components – for fast assembly and rebuild

- Tested, dimensioned and approved in line with European FEM norms

- Extensive range of accessories

Medium Span Shelving

-

Hi280 Medium Span shelving or 'Longspan shelving' is perfect if you're storing larger or heavier products across multiple pick-locations. The Hi280 Medium Span Shelving is assembled in the same way as the Standard Hi280 Shelving and suitable for both static and mobile requirements. It's particularly well-suited for the storage of automotive components.

Standard Hi280 Shelving is compatible with the Hi280 Medium Span. The two shelving systems can be easily combined and configured. Eliminating the need for cross-bracing maximises storage for its depth. It's a solution manufactured from pre-galvanized steel, resulting in a high, consistent quality and with a focus on using a minimum number of components as possible.

The Hi280 Medium Span offers the following features and benefits as standard:

- Easy assembly and disassembly

- Fully galvanized and durable

- Customisable shelving profiles for extra strength and stability for shelf supports

- No loose parts, and no sharp edges

- Shelf supports with recessed labels and barcodes

- Extensive range of accessories

Mobile Shelving System

-

The Hi280 Mobile Shelving System comes mounted on mobile units running along rails; matching the depth and width of standard Hi280 shelving sizes. As a result of only needing one aisle for access, installations in a warehouse can double the capacity of storage.

The Hi280 Mobile Shelving System offers the following features & benefits as standard:

- High quality – manufactured from pre-galvanized steel, with mobiles made of epoxy coated steel

- Mobile-base wheels run on rails – floor-inlayed, or mounted directly on top of an existing surface

- High loads up to 15 tons – yet easily moved for additional mobility

- Extensive range of versatile accessories

- Electronic options available such as 'touch control' for easy access

- Compact shelving systems create secure and efficient storage – mobile units lock together to allow single-person access

Multi-tier Shelving System

-

With integrated mezzanine, the Hi280 Multi-tier Shelving system is shelving constructed as two or more levels. Perfect if you have a larger warehouse storing multiple items. Providing greater storage capacity than standard shelving, the Multi-tier Hi280 allows for a structural mezzanine floor – built from Hi280 pre-galvanized uprights – above the base, with further shelves on top.

The Hi280 Multi-tier Shelving system offers the following features and benefits as standard:

- Substantial saving on construction costs due to efficient design

- Based on well-known shelving system Hi280

- Heavy-duty uprights to carry loads from the floors above

- High sustaining-capacity of individual components for optimal storage

- Fire sprinkler and lighting systems easily incorporated

- Stairs, handrails and pallet gate accessories complement the system

Narrow Aisle Shelving

-

The Hi280 Narrow Aisle Shelving system is well-suited for your 24hr operation. Compared to forklift handling, this is your narrow-aisle solution that works with automated cranes to optimise storage space and picking efficiency. A shelving system in a narrow aisle installation demands accuracy and high stability. The Hi280 Narrow Aisle Shelving System delivers on all fronts.

In fact, with easy access for man-up trucks, or handling by automatic cranes, a narrow aisle storage installation offers a unique optimisation of storage space. Eliminating the need for cross-bracing also maximises storage for its depth. It's a solution manufactured from pre-galvanized steel, resulting in a high, consistent quality and with a focus on using a minimum number of components as possible.

The Hi280 Narrow Aisle Shelving system offers the following features and benefits as standard:

- Frame components and shelves manufactured in pre-galvanized steel

- Based on the principle of a minimum number of components – for fast assembly and rebuild

- Tested, dimensioned and approved in line with European FEM norms

Longspan Shelving

-

With our Longspan shelving's modular design, and fast and easy assembly you can achieve the maximum possible storage capacity, regardless of the space you have available. The Longspan Shelving system allows for the easy adjustment of storage heights and configurations as your requirements change; providing a system that moves and changes with you.

Longspan is equally suited for warehouse and office environments; easily configurable for a number of different applications. From low level hand-loaded shelving, to high-rise systems. Incorporating varying frame and beam sizes, customising the system for your exact needs is really straightforward. Medium- and Longspan bays can be combined in the same rack, and a bolt-free, lock-in system ensures support beams remain in position. Longspan frames and beams are powder-coated anthracite and grey white. Our Longspan shelving has been designed and tested to comply with the recommendations of the FEM Shelving Design Code 10.2.06.

Ship Shelves & Cabinets

-

Keeping things shipshape when you’re on the high seas can be a problem, which is why we developed ship shelving. Based on the popular Hi280 system, it’s a special solution for teams working in marine industry applications. The shelving system Hi280 for marine use has been developed as a safe and secure storage system in marine environments.

This has resulted in further design and development of an extensive accessories range to prevent stored items from moving around during rough conditions.

The shelving system Hi280 has been reinforced and equipped with special, front-secure-beams fixed in front of the shelves, as well as a special locked chest of drawers for smaller components. The shelving system is mounted into fixtures of the ship for optimal stability and security. Clients include NATO war ships, ferries, container ships, tankers, oil platforms and ship yards.

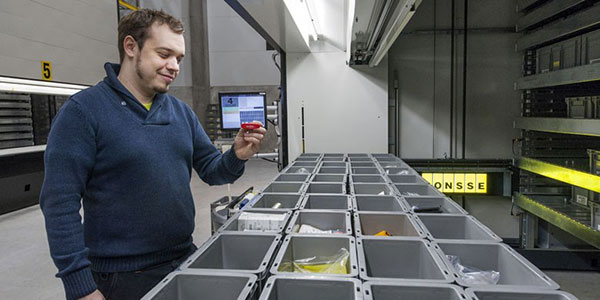

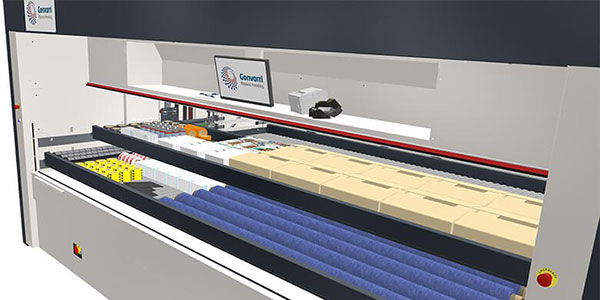

Mini Load

- The mini load system is a dynamic, ergonomic automated solution for the retrieval of small parts. Its high density, high accuracy, high throughput will increase the output of your operators. Stacker cranes are integrated with your warehouse management system, they pick up the tote boxes or trays and deliver them to the picking zone either directly or by conveyor. The system is available in heights up to 15m and the cranes can manage loads up to 50kg for light loads (tote boxes) and 200kg for trays.

Storage Machines

- If you're a warehouse or storage operative, you'll know the importance of making every square meter count. Our automatic storage systems can save you up to 70% on existing floor space, reduce picking errors by up to 70% and decrease picking time by more than 60%. Computer-controlled, the vertical or horizontal storage machines easily integrate with your existing warehouse management system, but also operate effectively as a standalone solution. Can you afford not to improve the efficiency of your storage and picking process with an automated solution built around you?

Lagerlift TORNADO

-

The TORNADO Automated Vertical Storage Machine is a dynamic storage and retrieval system that boosts handling efficiency by up to 65%, and increases floor space capacity by up to 70%.

An ultra-fast, virtually noiseless, computer-controlled storage and transfer lift system, the TORNADO is designed to maximise storage on the smallest possible footprint. Using the goods-to-person principle it cuts operator walking and waiting times, reduces search time and picking errors making it highly- efficient and energy-saving.

The TORNADO lift system is highly customisable for specific operating environments and offers the following benefits as standard:

- Up to 70% saving in floor space capacity

- Up to 65% boost in handling efficiency

- Fast and accurate picking with up to 99.9% stock-picking accuracy

- Low power consumption & maintenance costs

- Dedicated, easy-to-use Windows-based interface

- Equipped with adaptable trays for additional efficiency

- Light pointer to reduce errors

- Additional openings for use on different floor levels

- Easy and paperless order handling to optimise warehouse logistic

Tower Storage Machines

-

Tower Storage Machines are designed for storing and handling of various types of heavy goods, especially material made of metal. Tower Storage Machines are often used in the production for intermediate storage of material, near the cutting or bending machines, or as an inter-operative warehouse. The material stored is typically sheet metal or profile rods and tubes. The vertical system can be fitted with more operator areas, either at front and/or at the side.

The operator area design allows you to load and unload entire packages of heavy material using a forklift, or to handle individual pieces, manually by a crane or automatically with in-out feeder. It can be equipped with a weighing scale to register the weight of the material being loaded or unloaded.

It is possible to combine individually working Tower Storage Machines to create a controlled multi-warehouse system:

- Mono Tower - simple vertical storage system with one tower, lift and fixed operator table.

- Double Tower - set of two storage towers, with a single lift. Horizontal trolley transfers the loading unit from/to the operator area.

- Multi Tower - system compiled as a module combination of Double Tower(s). The combination creates a large storage capacity.

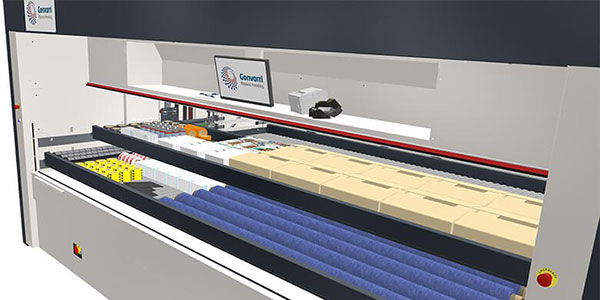

GonvaLift

-

The new GonvaLift is faster, moves more quietly and offers even more safety for people and stored goods. At the push of a button, it brings the “goods to the person” and looks really good in its new modern design. Even more efficient, safer and ergonomic order picking.

The GonvaLift has many new functions such as:

- Increased safety due to the locking of the tray in the operating opening

- Greater efficiency due to faster tray changes and higher storage capacity

The new vertical lift is designed without the need for any additional moulding, so installation is quick and easy. It is divided into multiple speed zones, which makes tray switches faster and safer.

The advantages of the GonvaLift at a glance:

- Increased speed and silent functions

- Multiple speed zones, including both ‘slow’ zone for enhanced safety, and ‘high’ zone for fast tray switching

- Two tray locations at the picking opening

- Efficient and accurate order picking performance

- Lower energy consumption

- Enhanced safety solutions, with trays at opening locked in position and emergency stop close at hand

- Password protected access levels for added security

- Possibility to access your machine remotely and IoT connectivity to provide proactive support and guidance

- Windows-based WMS system allowing easy integration into existing IT environment

- Easy and fast installation

- Practical and highly efficient with large capacity and sleek design

- Safety light barriers replace inner door

- Quick and easy installation due to pre-assembled modules

Long Goods Storage - Cantilever

-

If you're looking for safe, organised storage of your long and heavy goods, then why not try our made-to-measure Cantilever systems for size. Designed to meet nothing less than your precise requirements, our Cantilevers are exceedingly versatile whatever your work environment, and with no front uprights, all levels are available to forklifts.

Our Cantilever Racking, Rollrack, Timber locker, and A-rack* are all specially designed to store various length items – steel bars, pipes, tubes, furniture, packs of timber; as well as boards, metal sheets, crates and boxes, or white goods.

TELEKANT

-

The TELEKANT rack is a product which helps to address the issues of storage of bars in mechanical engineering and locksmith operations. Storage of metal profiles in their standard length of 6 or 12 meters is a relatively complex task, in particular due to difficult handling in storage. TELEKANT cantilever rack with extendable arms allows safe manipulation of long profiles by crane. It is designed and intended for this type of operation.

Due to the ability to service the cantilever rack with a crane, up to 80 percent of the current handling area can be changed into a productive area. The TELEKANT rack can be installed in less accessible places or in close proximity to machinery that processes the stored material. Also, the level of safety as well as speed and comfort when handling the profiles by crane is substantially higher.

Light & Medium Duty Cantilever

-

The Light & Medium Duty Cantilevers are ideal if you're having to store long and difficult items such as steel bars, piping, tubes or timber. Storage is horizontal so you can handle things manually or by forklift.

The Light Duty Cantilever is a versatile, modular system for storage of long goods. With no front uprights obstructing load-placing and retrieval, all levels are available for DIY, Manufacturing, Plumbing & Pipework, and workshop environments.

The Medium Duty Cantilever is positioned to bridge the gap between our Light Duty and our Heavy Duty option and is the preferred solution for storing long and large goods such as pipes, beams or pieces of furniture. The system is designed for medium weight goods, of large sizes which can be handled manually or by using a forklift truck. Additional arms, uprights and braces can be added as storage.

Both, Light & Medium Duty Cantilevers offer the following features and benefits as standard:

- No limitation to products length

- Suited to interior installations

- Various arm lengths available

- Easily adjustable arm distances

- Fully modular, with extra sections available as you need them

Heavy Duty Cantilever

-

The Heavy Duty Cantilever is ideal if you need to store long and difficult items such as steel bars, piping, tubes or timber. Storage is horizontal, so can be handled manually or by forklift. The Heavy Duty Cantilever is a versatile, modular system for storage of long or large goods. It's perfect for all types of warehousing environments, and with no front uprights obstructing load placing and retrieval, all levels are available to a forklift.

The Heavy Duty Cantilever offers the following features and benefits as standard:

- Totally bespoke system according to user requirements

- Columns, bases and horizontal arms – creating a complete structure

- Ideal for safe and efficient storage of long or large goods

- Maximises horizontal space

- Adjustable length and spacing between profiles

- Can also be installed on a MOVO heavy duty mobile trolley

- Efficient design with latest software, and compliant with IPE European standards, set by FEM and EN

Mobile Cantilever

-

Cantilevers are widely recognized as being highly effective for storing long and difficult items. Mobile systems are widely recognized as being highly effective for freeing up space and adding capacity. Put the two together, and you have the ultimate storage solution that maximizes every centimetre of useable space.

Mobile cantilever racks are standard cantilever racks that are mounted on mobile galvanized trolleys. With no front uprights to obstruct load placing and retrieval, Mobile Cantilevers need only one aisle open at a time using rails that are sunk into the floor. The trolleys are operated via an easy to use control panel or remote control. With numerous user functions and customization, Mobile Cantilevers offer an excellent solution in many warehouse or workshop environments.

The Mobile Cantilever offers the following features and benefits as standard:

- Relatively cheap cantilever racks because standard components are used

- Height-adjustable carrying arms

- Increases the range of goods that can be stored

- Save approx. 67% of the space required for static cantilever racks, increase the storage capacity by up to 200%

- Wide variety of accessories

- State-of-the-art technology for perfect support of optional functions and a touchscreen with clear graphic display for optimal visibility

- Designed according to the European directive 2006/42 / EC and DIN EN 15095.

Rollrack Long Product Storage

-

Rollrack Long Product Storage is your only true solution for storing certain long goods. Want a rational and economical cantilever alternative? Rollrack provides a 'honeycomb' of vertical dividing beams, giving you easy access to a pigeon-hole bay.

The Rollrack is the rational alternative to traditional cantilever solutions. It's an advantageous system since goods are loaded and unloaded from the short side – the front – consequently creating less demand in the handling area.

Above each pigeon hole: a set of longitudinal fixed rails, each with a set of ball-bearing rollers. As the goods are fed into the rack, the cradle facilitates movement, allowing for easy insertion of long items into the Rollrack such as profiles, piping and mouldings.

PALOMAT®

-

Efficient and safe pallet flow without physical strain on your staff.

Ideal for companies, who have a need for handling empty pallets at floor level. The PALOMAT® has a maximum capacity of up to 25 pallets. With the use of a simple pallet truck, the pallets are placed into the dispenser where they are then efficiently and automatically stacked. A user-friendly touch panel on the side is used to access various functions. The PALOMAT® range ensures efficient and safe pallet flow without physical strain on your staff. With the use of a simple pallet truck, the pallets are placed into the dispenser where they are then efficiently and automatically stacked. Fully automatic or semi-automatic stacking and destacking of the empty pallets.

The advantages of the PALOMAT®

- Space saving and a tidy workplace

- Optimised pallet flow

- Significantly less forklift movements

- Reduced pallet costs

- Increased efficiency

- No manual pallet handling

- Less absence due to illness

- Reduced time spent per pallet

- Fewer back injuries, jammed fingers and feet

- Leaner - increased efficiency with less resources

PALOMAT® Double Up

-

Fully automatic stacking and destacking. Choose a PALOMAT® Double Up, if you plan to both stack and destack 1+1 pallets together in a line and wish to use only electricity as the power source. The

PALOMAT® Double Up is completely AC operated. You can place it anywhere with an available AC 230V outlet. This will immediately give you efficient and more flexible pallet handling – if your pallet flow changes, it is easy to reposition the PALOMAT® to a new location. Pallets can be inserted and picked up using a hand pallet truck, electric stacker or a full-size forklift truck. All pallets are handled at floor level.

The PALOMAT® range ensures efficient and safe pallet flow without physical strain on your staff. With the use of a simple pallet truck, the pallets are placed into the dispenser where they are then efficiently and automatically stacked. A user-friendly touch panel on the side is used to access various functions.

PALOMAT® ½ Pallets

-

Fully automatic stacking and destacking. Choose a PALOMAT® ½ Pallets if you plan to both stack and destack single ½ pallets. A Greenline version for handling pallets in cold rooms with temperatures as low as –25°C / –13°F.

PALOMAT®½ Pallets is offered both as a Greenline (AC operated) and a Flexomatic (air + AC operated) version. Pallets can be inserted and picked up using a hand pallet truck, electric stacker or a full-size forklift truck. All pallets are handled at floor level.

The PALOMAT® range ensures efficient and safe pallet flow without physical strain on your staff. With the use of a simple pallet truck, the pallets are placed into the dispenser where they are then efficiently and automatically stacked. A user-friendly touch panel on the side is used to access various functions.

PALOMAT® Adjustable

-

Fully automatic stacking and destacking. Choose a PALOMAT® Adjustable if you plan to both stack and destack two different pallet sizes in the same magazine – one pallet size at a time.

The PALOMAT® Adjustable operates on compressed air and requires electricity for control of the machine. With PALOMAT® Adjustable, you can handle 1200x800 mm and 1200x1000 mm pallets in one and same magazine. The shift between the two pallet sizes takes approximately 5 seconds – a light press on a button plus a manual push or pull in the pallet magazine’s left side, which will afterwards adjust. Pallets can be inserted and picked up using a hand pallet truck, electric stacker or a full-size forklift truck. All pallets are handled at floor level.

The PALOMAT® range ensures efficient and safe pallet flow without physical strain on your staff. With the use of a simple pallet truck, the pallets are placed into the dispenser where they are then efficiently and automatically stacked. A user-friendly touch panel on the side is used to access various functions.

PALOMAT® 5

-

Semi-automatic stacking and destacking. Choose a PALOMAT® 5 if you plan to both stack and destack more than one pallet at a time – up to 5 together and wish to use only electricity as the power source. The PALOMAT® 5 is completely AC operated.

You can place it anywhere with an available AC 230V outlet. This will immediately give you efficient and more flexible pallet handling – if your pallet flow changes, it is easy to reposition the PALOMAT® to a new location. Pallets can be inserted and picked up using a hand pallet truck, electric stacker or a full-size forklift truck. All pallets are handled at floor level.

The PALOMAT® range ensures efficient and safe pallet flow without physical strain on your staff. With the use of a simple pallet truck, the pallets are placed into the dispenser where they are then efficiently and automatically stacked. A user-friendly touch panel on the side is used to access various functions.

PALOMAT® Flexomatic

-

Fully automatic stacking and destacking. Choose a PALOMAT® Flexomatic if you plan to both stack and destack single pallets and wish to use compressed air + electricity as the power source. PALOMAT®Flexomatic operates on compressed air and requires electricity for control of the machine. Pallets can be inserted and picked up using a hand pallet truck, electric stacker or a full-size forklift truck. All pallets are handled at floor level.

The PALOMAT® range ensures efficient and safe pallet flow without physical strain on your staff. With the use of a simple pallet truck, the pallets are placed into the dispenser where they are then efficiently and automatically stacked. A user-friendly touch panel on the side is used to access various functions.

PALOMAT® Greenline

-

Fully automatic stacking and destacking. Choose a PALOMAT® Greenline if you plan to both stack and destack single pallets and wish to use only electricity as the power source. PALOMAT® Greenline is completely AC operated. The PALOMAT® range ensures efficient and safe pallet flow without physical strain on your staff. With the use of a simple pallet truck, the pallets are placed into the dispenser where they are then efficiently and automatically stacked. A user-friendly touch panel on the side is used to access various functions.

The PALOMAT® Greenline is also available for handling pallets in cold rooms with temperatures as low as –25°C / –13°F (Only available for 15 pallets / 500 kg.). You can place it anywhere with an available AC 230V outlet. This will immediately give you an efficient and more flexible pallet handling – if your pallet flow changes, then it is easy to reposition the PALOMAT® Greenline to a new location. Pallets can be inserted and picked up using a hand pallet truck, electric stacker or a full-size forklift truck. All pallets are handled at floor level.

Workspace Optimisation

-

Central to improving your business workflow and boosting overall efficiency, is often about creating a first-rate working and storage environment.

Dexion's extensive range of systems and products can optimise all your storage and work areas where it really matters. From providing extra space and offices with mezzanine flooring and partitioning; protecting your teams with wire- and anti-collapse meshing, or providing secure personal storage for your workforce with our range of lockers and cabinets.

Mezzanine Floor Structures

-

Our Mezzanine Flooring Structures provide you with a cost-efficient way to create extra floor space in your existing buildings. Simple yet effective, you can combine the uprights and beams to form heavy duty, multi-functional structures.

The system includes high-quality stairways, strong railings and three different kinds of pallet gates to suit even the most complex of warehousing or storage requirements. Totally demountable and reusable, it's a far more economical solution compared to concrete constructs.

Mezzanine Floor Structures offer the following features and benefits as standard:

- Multifunctional for a variety of users

- Up to 1000kg/m2

- A span up to 10 meters

- A more economical solution than concrete

- Easy to erect in existing buildings

- Light transparent (with steel grid floors)

- Free-standing (no additional loads on building columns)

- Minimal additional pressure on the foundation floor

All Mezzanine floor railings, stairs and pallet gates have a scratch-resistant, powder-coated finish, and meet all the strictest of European compliance and safety regulations.

Partition Cassette900

-

Cassette900 is a pre-manufactured, flexible steel partition system. You can use it to improve the working environment for your employees against issues such as unacceptable noise, Electro Magnetic Pulses (EMP), dirt or dust. Cassette900 is a complete modular partition building system, easily adapted for different applications within industry workshops or offices.

It can be built as one-, two- or three-tier installations; integrating as a mezzanine installation, or constructed suspended from the ceiling. The range also includes pre-manufactured movable offices, delivered ready for use wherever there is a demand for a workshop office.

Our Partition Cassette900 offers the following features and benefits as standard:

- Suitable for use in heavy mechanical industry and high-technology electronic industries

- Modular system based on pre-manufactured steel cassettes for walls and ceilings

- Filled with noise-reducing mineral wool

- Designed to meet load capacity requirements and specified levels of noise reduction

- Constructed from fire-resistant material

- Partition elements available in 50mm or 100mm thicknesses and heights from 525mm –3500mm

- Shields against EMP disturbance

Lockable Storage Cabinets

-

Looking for personal storage for employees and individuals? Dexion's Lockable Cabinets are the ideal solution in schools, stores facilities or in municipal and governmental institutions. The LOCK-program consists of four different sizes of cabinets – LOCK5, LOCK10, LOCK16 and LOCK20.

The basic models of the smaller cabinets are equipped with:

- Two shelves and one extendable drawer as standard

The two larger standard cabinets are equipped with:

- Four and five shelves respectively, and supplied with a range of accessories

Steel Drawer Chests are supplied with either 8 or 12 drawers, and there is a large range of different dividing partitions.

All models can be equipped with casters for full portability.