- Offer Profile

-

We Are Moving the Future with Innovative Technologies.

The innovative company for smart sensor and image processing technologies. Many patented product and system solutions are used in countless automated industries worldwide. Constant growth, outstanding products and excellent corporate governance qualify wenglor sensoric group as a top employer in the SME sector.

Sensors

- Sensors are the sensory organs of smart machines. Thanks to a wide range of functional principles, they solve a variety of applications quickly, safely and sustainably. From photoelectronic sensors to ultrasonic sensors, inductive sensors and fluid sensors, as well as safety technology and software solutions for sensor operation and parametrization – the comprehensive portfolio offers the right solution for all types of factory automation. In addition to the wide range of functional principles, users also benefit from the broad selection of designs that enable the sensors to be installed in any industrial system.

Photoelectronic Sensors

-

Contactless Detection of Objects

Photoelectronic sensors can detect or count objects without contact, measure distances and detect colors, gloss or luminescence using light. The additional connection of special fiber-optic cables permits their use in extreme conditions such as cold, heat or limited space.

Laser Sensors for Distance Measurement

- Sensors in this category can detect or count objects without contact, measure distances, and detect colors, gloss or luminescence using light. The additional connection of special fiber-optic cables permits their use in extreme conditions such as cold, heat or limited space.

Reflex Sensors

- In the case of reflex sensors, the emitter and the receiver are located in the same housing. The emitted light is reflected and recorded by the object, the evaluation is carried out according to the energy principle or via angle measurement. Objects can be detected with or without defined background.

Reflex Light Barriers

- Reflex light barriers detect and control objects by evaluating the signal strength and the principle of angle measurement. Contamination and temperature fluctuations can be compensated for thanks to the dynamic readjustment of the switching threshold. Through teach-in, transparent objects with a defined background can also be detected without additional reflectors.

Retro-Reflex Sensors

- Reflex light barriers and retro-reflex sensors work with different light sources, whereby the emitter and receiver are located in one housing. When the light beam between the emitter and the defined background or reflector is interrupted, a switching signal is output.

Through-Beam Sensors

- Through-beam sensors detect and count small parts, detect the edges of objects and monitor passages in systems. The emitter and receiver are housed in separate housings according to the through-beam mode. The sensor switches as soon as an object interrupts the laser light, red light or infrared light.

Fork Sensors

- Fork sensors work with either red light or a collimated laser light beam. The emitter and receiver are arranged opposite each other in a plastic or stainless steel housing. Fork sensors with collimated laser light beam are particularly effective for detecting the smallest objects or clear glass.

Fiber-Optic Sensors

- Fiber-optic sensors are ideal for detecting small parts. They use plastic or glass fiber-optic cables, which can also be used in hard-to-reach places due to their high flexibility. Plastic or glass fiber-optic cables are connected to fiber-optic sensors for use in applications with limited space or high temperatures. They offer advantages such as high sensitivity, quick response time and robustness.

Light Curtains

- Light curtains operate according to the retro-reflective or through-beam mode and consist of several beams arranged in a row and connected to one another. In industrial use, they are suitable for applications such as pick and place or for measuring tasks such as height or position checks.

Retro-Reflex Sensors with Light Band

- Retro-reflex sensors with light band detect objects with variable edges, shapes and sizes. Thanks to the continuous, homogeneous laser light band, the sensor monitors a much larger area than a light barrier with a dot-shaped light spot. The light band can also detect small or translucent parts.

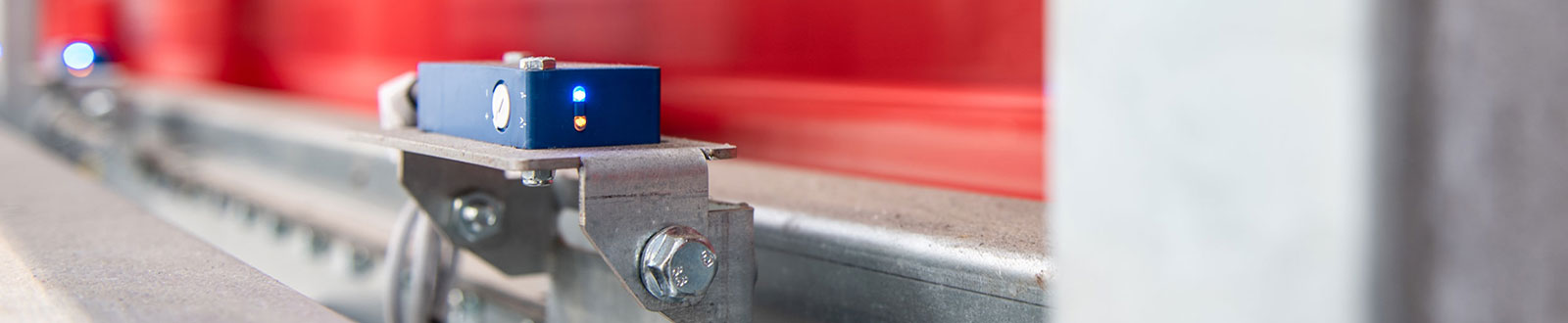

Sensors for Roller Conveyor Systems

- Sensors for roller conveyor systems detect objects on electrically or pneumatically controlled conveyors. The format is specially adapted to the design of roller conveyors and is therefore safe from mechanical influences. The sensors are available with or without accumulation logic and as reflex sensors or light barriers with a reflector.

Contrast Sensors

- Contrast sensors with switching or analog output measure the brightness of objects. Sensors with switching output compare the brightness level with a reference value in order to detect contrast marking, for example. Sensors with analog output provide the measured brightness as a proportional voltage signal in order to monitor brightness curves, for example.

Print Mark Readers

- These sensors distinguish between up to 100 different gray tones and can detect print marks against any background – regardless of brightness or color values. Thanks to the durable white light LED, a light spot with high contrast resolution is produced. The setting is made using various teach-in modes.

Color Sensors

- Color sensors analyze the finest color nuances in automated processes at high speeds and select colored objects based on previously defined reference colors. Thanks to the pulsed white light, the sensors are insensitive to ambient light.

Luminescence Sensors

- Luminescence sensors emit UV light with a wavelength of 375 nm to illuminate luminescent materials. The sensors thus detect markings, for example on labels, which are not visible to the human eye.

Temperature Sensors for Contactless Measurement

- Sensors of this type measure the temperature of objects contactlessly using infrared radiation – regardless of material, size and state of aggregation. Two switching outputs and an analog output enable the comparison of target/actual values as well as absolute measurements.

Gloss Sensors

- Gloss sensors can differentiate between glossy and matte surfaces.

Ultrasonic Sensors

-

Ultra-Smart. Ultra-Strong. Ultrasonic.

Ultrasonic sensors are suitable for detecting transparent, dark, glossy, reflective or porous surfaces. They can detect objects or liquids despite the presence of dirt, dust, mist or extraneous light. The measured values are determined by transmitting and receiving ultrasonic waves which are output as voltage or via IO-Link.

Ultrasonic Distance Sensors

- Distance sensors are suitable for the detection, differentiation and measurement of objects by means of ultrasound. Different operating modes, such as synchronous, multiplex or through beam mode, can be set via the display or centrally via IO-Link, and different output variants and designs enable a wide range of possible applications.

Fork Sensors for Label Detection

- Ultrasonic fork sensors detect labels on any carrier material regardless of color, transparency or surface quality. The label on the carrier material attenuates the ultrasound more strongly than the carrier material itself; a small gap is sufficient for differentiation. The setting is made via the teach-in key.

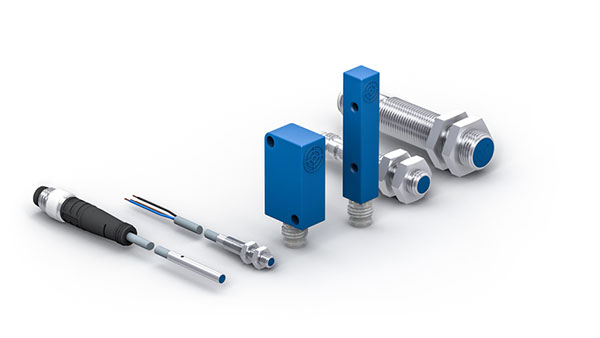

Inductive Sensors

-

Reliable Object Detection with Induction

Inductive sensors detect metallic objects through electromagnetic induction. The many formats, housing materials and wide switching distances ensure a wide variety of applications. Due to the fact that no moving parts are used, these sensors are maintenance-free, waterproof and impervious to contamination and impacts.

Inductive Sensors with Standard Switching Distances

- Inductive sensors with standard switching distances detect metal objects contactlessly using electromagnetic induction. Thanks to different ranges and different formats and housing materials, they detect the presence of moving parts even in the event of dirt or vibrations.

Inductive Sensors with Increased Switching Distances

- Inductive sensors with increased switching distances offer up to three times the switching distances compared to standard inductive sensors. The integrated weproTec technology ensures fault-free operation of several sensors that are operated directly next to one another.

Inductive Sensors with IO-Link

- Inductive sensors with IO-Link communicate from the field level to the control. Preventive maintenance is possible via a special diagnosis output. Variable switching distances and frequencies offer a wide range of applications. The sensor output (either PNP or NPN) can be programmed as NC or NO.

Inductive Sensors with Full-Metal Housing

- Inductive sensors with full-metal housing made of stainless steel 316L (1.4404/V4A) are impact-resistant, resistant to chemicals and high water pressure (IP68/IP69K). The sensors with additional ATEX approval for 3G and 3D areas are suitable for applications with a high risk of explosion.

Inductive Sensors with Analog Output

- Sensors of this type detect metallic objects and output the distance as a proportional voltage signal, even in dirty environments. The switching distance is identical on different metals, so the correction factor is 1. They also feature an almost linear output voltage.

Inductive Sensors Welding Field Resistant with Correction Factor 1

- Sensors in this category detect objects of different metals with identical switching distance. Teflon coating protects the sensor from extreme effects during the welding process. The sensor is also very robust against magnetic direct and alternating fields.

Inductive Sensors with Selective Performance

- Inductive sensors with selective performance can differentiate between ferromagnetic metals (e.g. iron or steel) and nonferromagnetic metals (aluminum, brass, copper and stainless steel). The functional principle allows contactless and thus wear-free detection and differentiation of objects.

Inductive Sensors for Extreme Temperature Ranges

- These inductive sensors detect contactlessly metallic objects in extreme temperature ranges. With increased switching distances and a very robust design, the sensors are designed for a long service life of several years.

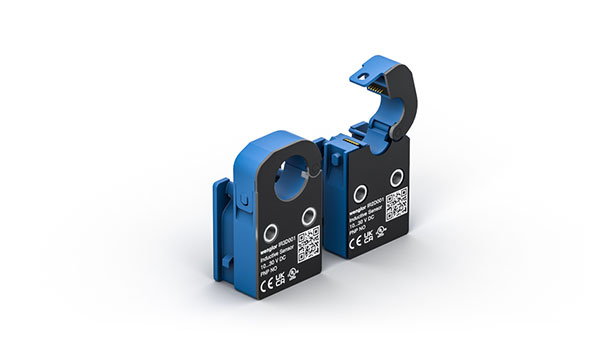

Inductive Ring Sensors

- Inductive ring sensors enable precise and reliable detection of small metal parts from a minimum size of 2 mm in feed hoses. The sensors can be quickly and flexibly mounted and removed from the hose thanks to the separable housing.

Fluid Sensors

- Fluid sensors detect parameters such as pressure, flow, temperature or fill level in liquid or gaseous media. The range of products includes models with one or two measuring functions, with an integrated analysis module and display, in stainless steel or plastic, and with IO-Link or two analog switch outputs.

Pressure Sensors

- Pressure sensors with integrated analysis module measure pressure for hydraulics, pneumatics and process technology. The weFlux² series, with which pressure and temperature are measured simultaneously, also has IO-Link. This allows parameter data to be configured and transmitted.

Flow Sensors

- Flow sensors operate according to the calorimetric principle and can be mounted independently of the current direction. weFlux² series models combine flow and temperature measurement; parameter settings or data transfer can be carried out via IO-Link.

Temperature Sensors

- Temperature sensors measure and monitor liquid and gaseous media with high accuracy and fast response times. Modular designs and process connections allow them to be used individually. The weFlux² series features IO-Link for setting parameters.

Fill-Level Sensors

- Fill-level sensors are integrated into processes that monitor liquids and solid media such as granules or powders. Two switching outputs provide independent signal values that are output when different media and states are detected.

Safety Technology

- Safety technology for body, hand and finger protection is used to protect both man and machine. Certified according to international standards, light barriers and curtains with or without muting functions, safety switches, locking devices, emergency stops, relays and protection columns protect all production systems.

Electro-Sensitive Protective Equipment

- Electro-sensitive protective equipment (ESPE) detects the entry of a person or part of the body into a safety field by means of optical sensors without direct mechanical contact. ESPE are therefore used to secure hazardous areas on machines.

Command Devices

- Command devices are used when safe communication between human and machine must be ensured. They are required, for example, to set up, start, shut down or end machines or automated processes.

Safety Guards

- Safety guards are a kind of physical barrier to protect people from the dangers of machines. They also protect the machine from humans when, for example, time-critical processes must not be interrupted by approaching people.

Safety Relays and Analysis Modules

- Analysis modules monitor through-beam sensors to detect interruptions and switch off the safety output. Safety relays evaluate signals from emergency stop switches and protective devices and enable standard-compliant safety functions in accordance with EN ISO 13849-1, EN 62061 as well as potential-free disconnection of machines.

Muting Sets

- Muting sets consist of muting sensors and booms that create a fully integrated muting station together with the safety light arrays or safety light curtains. The bridging feature allows for objects to be transported through the hazardous area of a machine or system.

Industrial RFID

- Industrial RFID readers emit electromagnetic waves to write data to transponders and read information without visual or physical contact. Robust designs and flexible functions enable clear identification, assignment and tracking of tagged objects – even in challenging process environments.

RFID Transponders

- RFID transponders save and transmit information they receive via electromagnetic waves from an industrial RFID reader. Objects equipped with transponders can be reliably assigned, tracked and identified by an RFID reader without contact.

Sensor Software

- Software products for sensors make it easy to set up and parameterize single or multiple sensors from a central controller. They also make it possible to carry out instrument-independent calculations, maintain sensors remotely and provide remote access to equipment in the event of support.

Configuration Software

- Configuration software makes it easy to set up and parameterize single or multiple sensors from a central controller. In addition to programs for photoelectronic and inductive sensors, software for ultrasonic and fluid sensors is also available.

Service Software

- Sensor service software makes it possible to perform instrument-independent calculations.

Machine Vision - Software

- Software for image processing technologies is used to set up and evaluate smart cameras, image processing systems and 2D/3D sensors. They allow adjustment and maintenance work to be carried out regardless of location.

uniVision 3 Image Processing Software

- Machine vision software uniVision 3 is an all-in-one software solution for setting up wenglor machine vision products for solving tasks in the field of machine image processing.

wenglor Discovery Tool

- The wenglor Discovery Tool is a software for searching for and finding wenglor Machine Vision devices in the network – regardless of the network configuration of the system or the PC and for adjusting the network configuration of the Machine Vision devices.

uniVision 2 Image Processing Software

- uniVision 2 image processing software is an all-in-one software solution for parameterizing numerous industrial image processing products and displaying the generated results.

VisionApp 360

- The VisionApp 360 software guarantees full 360° profile detection when using up to 16 2D/3D profile sensors. The sensors can be synchronized and calibrated with freely selectable arrangement and format by simple parametrization. The measured values are output via a TCP or GigE interface.

VisionApp Demo 3D

- The free VisionApp Demo 3D software enables the display of measurement data from 2D/3D profile sensors and 3D sensors. The data is displayed as point clouds which can be saved, loaded and transferred. Users configure their sensors via the intuitive software interface.

Support Software

- Support software enables remote access to the respective devices for analysis and troubleshooting in the event of support.

Machine Vision Controllers

- Machine vision controllers are analysis modules for processing all processes and for result output. The compact housing with fanless cooling ensures high performance. Different model variants in two performance classes allow connections for up to 16 devices at the same time, and various interfaces ensure ideal connectivity.

Machine Vision Cameras

- Machine vision cameras from wenglor deliver high image quality in a compact housing format. Thanks to image chips with global shutter, high-resolution images (1.6 and 5 MP) are possible even in dynamic applications; image chips with rolling shutter enable resolutions of 12 MP.

2D/3D Profile Sensors weCat3D

- Sensors of this type measure profiles of objects such as weld seams or glue beads and check roundness or gaps using laser triangulation. Red or blue laser light, open interfaces and various performance classes are available.

weCat3D MLSL 2D/3D Profile Sensors

- 2D/3D profile sensors from the weCat3D series use the principle of laser triangulation to create 2D height profiles and 3D point clouds. The MLSL model provides accurate resolution in a compact housing design.

weCat3D MLWL 2D/3D Profile Sensors

- 2D/3D profile sensors from the weCat3D series use the principle of laser triangulation to create 2D height profiles and 3D point clouds. The MLWL model offers unbeatable profile quality thanks to its optimized, high-quality optics.

2D/3D Profile Sensors Overview MLZL

- 2D/3D profile sensors from the weCat3D series use the principle of laser triangulation to create 2D height profiles and 3D point clouds. The MLZL model enables use in rough welding applications.

2D/3D Profile Sensors weCat3D Stainless Steel

- 2D/3D profile sensors measure objects 360° all the way around, precisely control the positions of robots and inspect surfaces with micrometer accuracy. The weCat3D stainless steel model is particularly suitable for cleaning-intensive washdown areas.

2D/3D Profile Sensors with Safe Laser Shutdown

- 2D/3D profile sensors from the weCat3D series use the principle of laser triangulation to create 2D height profiles and 3D point clouds. The laser from the S40 product group can be safely switched off and on without the sensor having to be switched off thanks to the certified laser switch-off according to EN ISO 13849-1:2016.

2D/3D Profile Sensors for Bending Machines

- 2D/3D profile sensors from the weCat3D series use the principle of laser triangulation to create 2D height profiles and 3D point clouds. The MLSL model for bending machines ensures reliable monitoring of bending angles throughout the bending process.

weCat3D 2D/3D Profile Sensors – The Special Solution

- wenglor offers special solutions for applications with unusual requirements. The technical properties are application-specific, such as UV lasers for transparent floodlights or extended measuring ranges for larger objects.

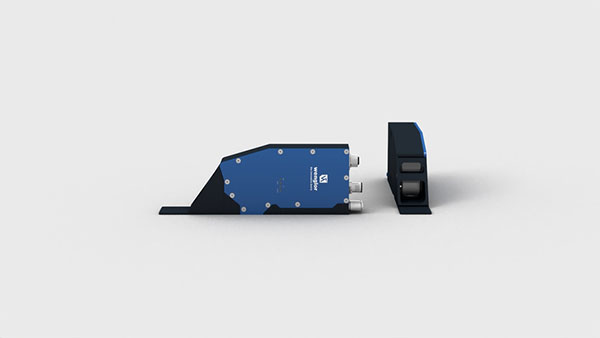

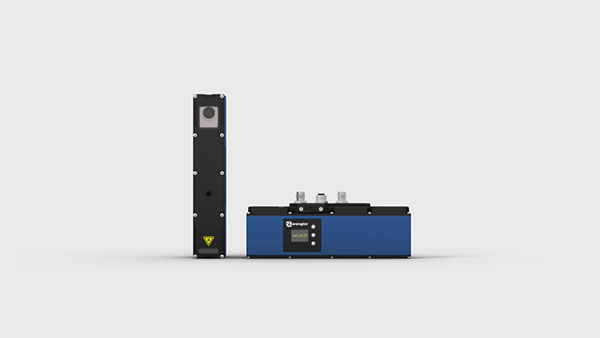

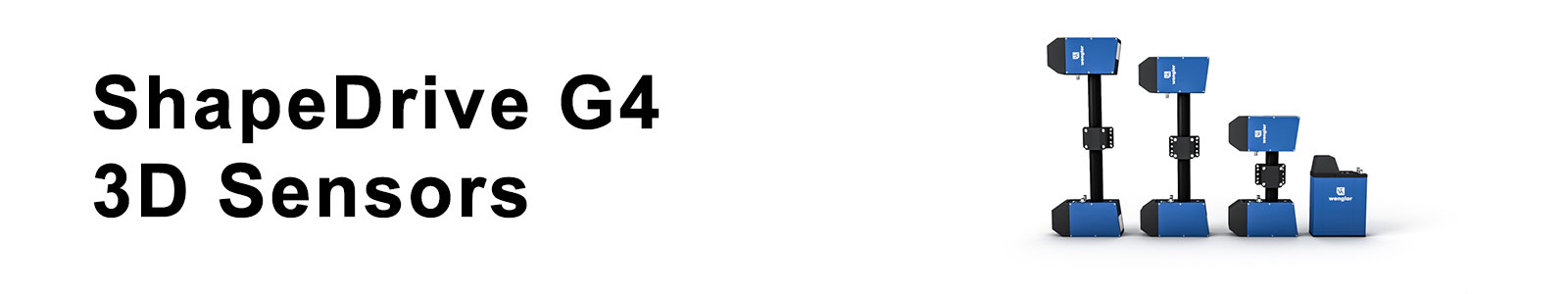

ShapeDrive G4 3D Sensors

- 3D sensors perform three-dimensional completeness, dimensional accuracy and surface checks. They make it possible to control robots, for example in pick and place or bin picking applications. 3D sensors project structured light patterns that are recorded and digitized as 3D point clouds using a camera. See the point cloud quality for yourself.

ShapeDrive G4 MLAS 3D Sensors

- ShapeDrive G4 MLAS 3D sensors are distinguished by high precision for small measuring volumes. The models are available with a resolution of 5 or 12 MP. This means that even the smallest structures are precisely detected. High-quality optics provide high-contrast illumination and pattern projection.

ShapeDrive G4 MLBS 3D Sensors

- ShapeDrive G4 3D sensors in the MLBS performance class are designed for detecting large measuring volumes thanks to their symmetrical design and powerful light engine. Short exposure times make the 3D scanners ideal for dynamic applications

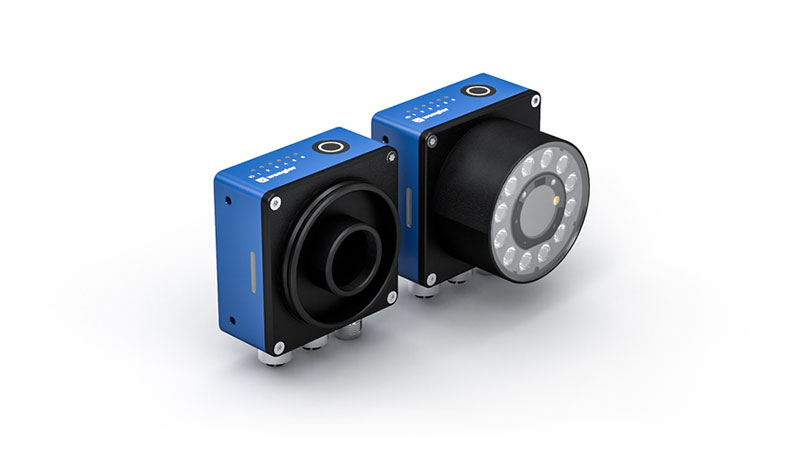

Smart Cameras and Vision Sensors

- Smart Cameras and vision sensors solve a wide range of industrial image processing tasks in real time. The highly modular hardware platforms in combination with high-performance Machine Vision software enable tailored adjustment for all Machine Vision applications.

B60 Smart Camera

- The high-performance smart camera B60 carries out a wide range of industrial image processing tasks. The highly modular hardware platforms in combination with powerful machine vision software offer the computing power of a vision system in the housing of a smart camera.

weQube B50

- The weQube B50 is available as a smart camera, vision sensor and OCR reader and solves a wide range of industrial image processing tasks in real time. The highly modular hardware platforms in combination with high-performance machine vision software enable tailored adjustment for all machine vision applications.

Illumination Technology for Machine Vision

- Illumination is a crucial component in the 2D machinevision illumination and code reading industry. It is the key to having robust and well-contrasted pictures for image processing. Machine vision lighting is constructed of LEDs, optics and diffusors. It can come in several housings and sizes to suit a variety of applications and environments, such as illuminating large fields of view or shiny surfaces.

Machine Vision Bar Lights (LED)

- Bar lights are a versatile illumination that can be utilised in many lighting conditions. wenglor bar lights are a linear array of LEDs with excellent brightness and homogeneity balance across many situations, such as creating a dark field effect to illuminate shiny parts or to create a brightfield effect to flood an area with powerful illumination. Various sizes, colors, illumination angles and diffusion options are available.

Machine Vision Ring Lights (LED)

- Ring illumination describes the shape of the illumination, constructed of a circular array of LEDs. Ring lights are normally positioned around a machine vision camera’s optical axis, giving the image a high-intensity brightfield effect. wenglor has a range of ring light products comprising of many colors, suitable for homogeneously illuminating at both large and small working distances.

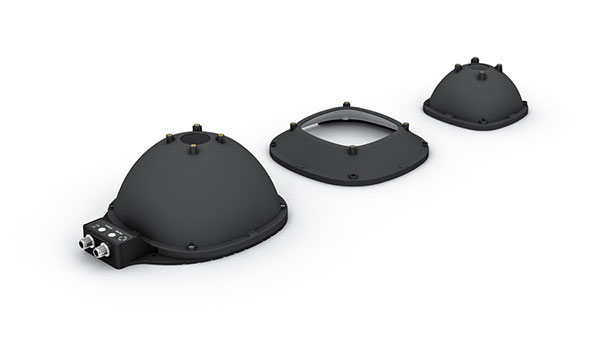

Domes and Dome Lights

- Dome lights are classically referred to as ‘cloudy day illumination’. It describes the lighting type that is a highly homogeneous and diffuse LED lighting that can eliminate shadows in the images. This means the illumination is excellent for the inspection of uneven surfaces. The highly diffuse lighting from a dome light is also suitable for the inspection of metals and shiny parts. wenglor dome lights use some novel features to assist with complex feature inspection.

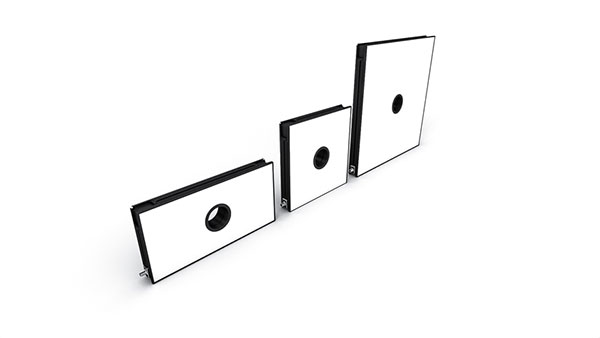

Machine Vision Flat Lights / Back Lights

- This category of illumination contains highly homogeneous area lights, typically used but not limited to backlighting. Backlights generate robust black-on-white contrast (silhouettes) – even on reflective surfaces. They can also be used to work closely to samples as a highly diffuse direct LED illumination. wenglor flat lights are available in many sizes with excellent brightness for ensuring high contrast.

Machine Vision Flat Dome Lights

- Flat dome lights are most often used as top lights or area lighting to homogeneously illuminate large areas. The name comes from the lighting effect being similar to a traditional dome light but created over a larger field of view. The housing is constructed like an LED flat light (or backlight) with a camera hole in the centre. Flat domes are typically used at double the size of the field of view to perfectly illuminate many types of surfaces.

Machine Vision Spot Lights

- Spot illumination is typically a highly focused light source, perfect for creating contrast on specific features from various working distances. Spots normally comprise of a small number of LEDs, this means they come in a small package that is easy to adapt into tight spaces whilst providing intense illumination exactly where it is needed. wenglor spot lights are designed to be easily integrated whilst providing bright and homogeneous illumination for image processing.

1D/2D and Barcode Scanners

- The scanners read all 1D and 2D codes using different types of light. The light arriving at and returning from the code is reflected to varying degrees on a specific receiving element, decoded electronically, and evaluated.

1D Code Scanners

- 1D code scanners use different technologies to read and decipher one-dimensional high-frequency barcodes. Variants with CCD line or laser technology offer precise reading results – even damaged or incomplete codes are decoded. Networking to control systems is possible via integrated industrial Ethernet interfaces.

1D/2D Code Scanners

- 1D/2D code scanners read printed, engraved, etched or directly marked codes at high speeds – regardless of the location, position or condition of the code. Data can be transferred via Industrial Ethernet and settings can be received via the intuitive user interface Weblink.

1D/2D Handheld Scanners

- Handheld scanners read all 1D/2D codes omnidirectionally, regardless of location and background. Decoding is indicated by vibration, acoustic or visual signals. The adjustment option between the near and far range accelerates the scan rate or increases the detection range. In addition to wired scanners, Bluetooth scanners are also available.

Configuration Software for Code Scanners

- Configuration software for code scanners enables setup and configuration of 1D/2D and barcode scanners.